Across the energy industry, the transition to carbon-neutrality and renewability is well underway – and batteries have an important role to play, particularly when it comes to energy storage. While renewable energy sources such as solar energy and wind are increasingly replacing fossil fuels, batteries have emerged as a viable energy storage option for future power grid applications. The shift toward electric transportation is also driving the development of battery technology, super-capacitors, as alternatives to less sustainable combustion fuels.

Nevertheless, the transition to low-carbon energy is far from over. Renewable energy technology, particularly for energy storage materials and devices, still has large potential for improvement. For instance, when it comes to battery energy storage technology, more efficient electrode materials are continually being discovered and quickly scaled up. Another important factor is enabling a circular value chain with efficient recycling of used and waste products.

Explore

Cathode Active Materials (CAM)

In operando XRD

Lithium-ion battery recycling

Choosing the best battery characterization instruments

At Malvern Panalytical, we are proud to partner with you in your contribution towards carbon neutrality through battery-based energy storage. We offer a wide range of physical, chemical, and structural solutions for the R&D and quality control of battery materials and cell production.

Our tailored analytical solutions stand as a testament to our commitment: delivering high-quality material analysis seamlessly integrated into both laboratory research and manufacturing environments.

Solutions for battery research and quality control

Micromeritics AccuPyc

Micromeritics TriStar II Plus

Particle size and shape measurement

Mastersizer range

Control particle sizes with high precision

Whether you produce your own active materials or you buy them from your suppliers, particle size and shape are the defining parameters not only for the battery performance, but also for the uninterrupted high-yield production process.

Particle size and shape govern the production yield of precursor materials, the rheology of the electrode slurry, packing density/porosity of the electrode coating, and ultimately the performance of the battery.

The best way to measure these is with a combination of laser diffraction and automated optical imaging. Mastersizer 3000+ is the industry benchmark when it comes to particle sizing through laser diffraction. Its counterpart, Insitec, can be used when real time online particle size analysis is needed for the control of grinding mill or the sieve. Particle shape can be measured with our Hydro Insight dynamic imaging system or the Morphologi 4 automated imaging system.

![[shutterstock_2216935905.jpg] shutterstock_2216935905.jpg](https://dam.malvernpanalytical.com/87a9b86d-c8c2-4e13-8d60-af860119a234/shutterstock_2216935905_Original%20file.jpg)

Mastersizer for battery applications

Learn more about the key applications of the Mastersizer 3000+ range in the battery industry >>

Crystal phase analysis of batteries

Aeris

Aeris XRD can analyze anode and cathode materials in just a few minutes to provide quality parameters like crystallite size.

The quality of the crystal phase is another critical parameter that governs the performance of battery materials like specific energy and discharge rate or capacity.

For cathode active materials, important parameters of concern are cation mixing and crystallite size, while for graphite anode, it is degree of graphitization (or graphiticity) in synthetic graphite and orientation index in the coated electrode. Crystallite size can also give an idea about particle size of nano-crystalline active materials like silicon-based anode.

If you are working on single crystal cathode materials, then measurement of crystallite size becomes even more critical.

Aeris XRD is a perfect tool to measure these important parameters both in cathode and anode manufacturing. With external sample loading and industrial automation, Aeris is easy to use and offers unmatched performance. Find out more about Crystalline Defect Analysis.

In-operando XRD analysis

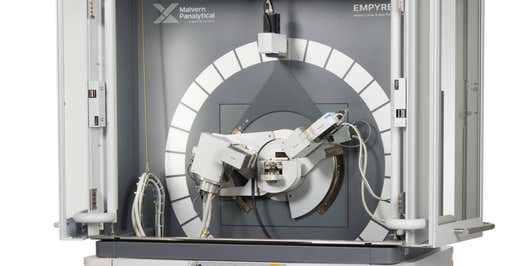

Empyrean

Platform for XRD, SAXS and in-operando analysis.

As the cell is cycled during formation and aging, electrode active materials undergo changes due to movement of Li ions and also due to the reaction with electrolyte at higher potentials.

In-operando XRD can track these changes at atomic scale and can provide an early warning for any potential issues with the battery cell. Empyrean XRD, can measure battery cells in-operando under simulated environmental conditions from -10 oC to 70 oC.

With renowned VTEC and VTEC-Trans stages, it can measure both the coin and the pouch / prismatic cell configurations. Combined with ultrafast hardware components and automated data analysis, Empyrean offers an innovative solution for R&D, as well as QC of fully assembled cells.

Elemental composition in battery production

For cathode active materials and their precursors, having correct elemental composition is equally important. Also important are the dopant and impurity concentrations both for the cathode and anode materials.

ICP is a common way of measuring elemental composition, however, it is expensive, time-consuming and involves hazardous chemicals. XRF can analyze most of these materials with relative ease.

Complementing our renowned Epsilon EDXRF and Zetium WDXRF systems is our new Revontium high end EDXRF system. Combined with our set of battery reference standards and Forj / Egon 2 fusion systems along with our expertise, we offer a complete solution that can match or even surpass the accuracy and precision of ICP analysis.

Online elemental composition analysis solutions include Epsilon Xflow for battery liquid precursors and Epsilon Xline for analysing the electrode coating.

Our expertise

Malvern Panalytical stands at the forefront of battery characterization, leveraging decades of analytical expertise to advance the development and performance of battery technologies. Our comprehensive suite of characterization tools and techniques addresses the critical needs of battery research, development, and production, ensuring optimal performance, safety, and longevity of energy storage systems.

Further reading

Electrifying the difficult segments with innovative battery technology

Graphitization degree and orientation index in graphite anode materials