Anode materials are essential components of lithium-ion batteries, playing a key role in determining energy density, lifespan, and safety. To have good performance in lithium-ion batteries, anode materials must meet several critical requirements:

- High Specific Capacity: The material should have a high specific capacity (measured in mAh/g) to store more energy effectively.

- Good Electronic Conductivity: High conductivity is necessary to reduce energy losses during usage.

- Good Ionic Conductivity: The material must allow easy movement of lithium ions in and out of the anode.

- Structural Stability: An effective anode material should maintain its structure during charge/discharge cycles to ensure reliability over time

Crystalline quality, particle size, and particle shape are the key parameters governing the quality of the battery anode materials.

Our solutions

Types of Anode Materials

Lithium-ion batteries utilize various anode materials, each with distinct properties that affect performance, capacity, and longevity. Below are the primary types of anode materials used in Lithium-ion batteries:

- Intercalation-based anodes

Intercalation-based anodes are layered materials and can store Li ions between the layers.

- Graphite and Carbon are the most widely used anode materials due to their high electrical conductivity, low cost, and stable structure with reversible intercalation of lithium ions. However, it has a relatively lower capacity compared to some newer materials. Hard carbons are used as anodes in Na ion batteries.

- Lithium Titanium Oxide (LTO) is Known for excellent cycle stability and safety, LTO does not undergo significant volume changes during lithium insertion and extraction. However, it has lower conductivity and operates at a higher voltage compared to other anode materials, which limits its capacity.

- Alloy-based anodes

Alloy-based anodes are metals or their oxides (Si, Ge, Sn, Sb, and Si/Sn oxides) that can form an alloy with Lithium.

Silicon offers a significantly higher theoretical capacity than graphite, potentially up to ten times more. However, silicon experiences substantial volume expansion during cycling, which can lead to mechanical failure and reduced cycle life. Research is ongoing to develop silicon composites that mitigate these issues, some of which are already commercialized.

- Conversion anodes

Conversion anodes are MX (M = Fe, CO, Mn, Ni, Cu, Cr, Mo, and X = O, P, S, N) which convert to (LiyX + M) upon charging. These materials are being researched for their unique electrochemical properties and potential benefits such as improved rate capability. Their drawbacks are voltage hysteresis and large volume expansion.

- Nanostructured anodes

Recent advancements focus on nanostructured anode materials that enhance surface area and reduce lithium-ion diffusion paths. These can include various combinations of carbon-based materials, silicon, and transition metals designed as core-shell particles or composites to improve performance metrics like capacity and cycling stability.

How do I characterize my battery anode materials?

Anode materials quality can be optimized by measuring and controlling the following parameters:

- Particle size and shape

- Crystal structure and defects

- Impurities

Find out more about how to control these below.

Particle size and shape

Whether you produce your own active materials or you buy it from your suppliers, particle size and particle shape are the defining parameters not only for the battery performance, but also for the uninterrupted high-yield production process.

Particle size and shape govern the rheology of the electrode slurry, packing density/porosity of the electrode coating, and ultimately the performance of the battery. The best way to measure these is with a combination of laser diffraction and automated optical imaging.

Mastersizer range

The smartest way to measure particle size

Mastersizer 3000+

Delivering the data you need, for the outcomes you can trust.

The Mastersizer range of laser diffraction particle size analyzers set the standard for delivering rapid, accurate particle size distributions. With its wide size range and best-in-class accuracy, Mastersizer 3000+ is the tool you need for Anode particle sizing from 0.01 to 3500 micrometre range. And when you get unexpected results on your sample, you have the Size Sure and data guidance tools for further investigation. Add in flexibility, ease of use, and Hydro Insight accessory for dynamic imaging, the Mastersizer truly is the top choice for particle sizing and beyond.

Further particle size and shape solutions

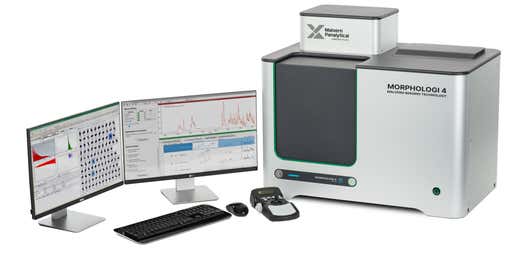

Morphologi 4-ID

Particle size and shape resources

Battery manufacturing: Reliable, adaptable particle sizing using the Mastersizer 3000+

The impact of electrode particle size and shape on battery slurry viscosity

Crystal phase

The quality of the crystal phase is another critical parameter that governs the performance of battery materials like specific energy and discharge rate or capacity. For battery anode materials, important parameters of concern are degree of graphitization, orientation index and crystallite size for graphite materials. Crystallite size can also give an idea about particle size of nano-crystalline active materials like silicon-based anode.

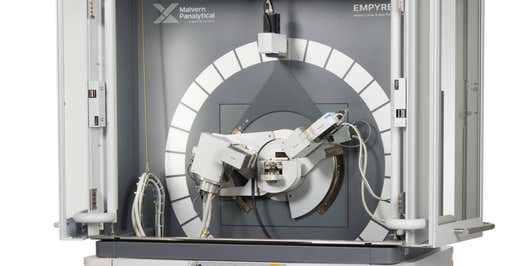

Aeris

The future is compact

Aeris XRD

The future is compact.

Aeris XRD can analyze anode and cathode materials in just a few minutes to provide quality parameters like crystallite size, graphitization degree, and orientation index. This is a compact plug-and-play XRD system, built with industrial robustness and safety. Moreover, it can be easily integrated into the process with belt or robot automation.

Crystal phase resources

Graphitization degree and orientation index in graphite anode materials

Elemental composition

For anode materials, measurement of dopant and impurity concentrations is critical to evaluate their performance. If it is a C-Si anode, then the relative concentration of Si determines capacity as well as stability.

ICP is a common way of measuring elemental composition, however, it is expensive, time-consuming, and involves hazardous chemicals. XRF can analyze most of these materials with relative ease.

Revontium

Compact brilliance, powerful analysis, endless possibilities

Revontium

Compact brilliance, powerful analysis, endless possibilities.

Revontium™ is a compact X-ray fluorescence (XRF) analyzer that delivers high-quality elemental analysis in a compact, tabletop format. It bridges the performance of floor-standing XRF and the versatility of table-top instruments.

Compact XRF offers a smaller physical and environmental footprint. Its cost of ownership can be more than 25% lower due to reduced need for consumables, extensive sample preparation, and maintenance.

Further elemental composition solutions

Elemental composition resources