Controlling the size distribution of droplets in sprays and aerosols is essential to ensure successful delivery of a product, whether it is a drug to a patient, a coating to a substrate, a pesticide to a plant, or fuel to an engine. This white paper explores the effectiveness of laser diffraction for the real time tracking of spray droplet size distributions for both rapidly-evolving and steady-state atomizer systems.

Many industries share the need to closely control the characteristics of sprays, albeit for very different reasons, and one of the most critical parameters is the particle size of the droplets within the spray plume. In pharmaceutical nasal sprays this is controlled to ensure successful drug delivery, while at the other end of the spectrum in agricultural crop sprayers, droplet size is manipulated to achieve the targeted delivery of pesticides and herbicides to a defined site with minimal drift. Droplet size also determines the efficiency and cleanliness of fuel combustion within an engine, and in spray coating it influences the quality of the finish for goods ranging from automotive parts to household furniture.

While individual industrial applications of sprays are too numerous to cover in a single paper, here we take a look at a cross-section that exemplify the variation in timescales and size ranges that spray characterization tools must accommodate. We examine how measuring spray droplet size distribution supports both product development and optimization studies in each case and consider the variable properties that can be used to control the characteristics of the droplets delivered. Example studies illustrate how real-time particle size information enables the intelligent manipulation of droplet size.

Sprays and aerosols are highly effective delivery vehicles for a wide range of industrially important products. The size of the droplets delivered in the spray dictates many aspects of product performance. Consequently there is a pressing need to measure spray droplet size distributions and to understand the dynamics of liquid atomization processes.

Timely and efficient droplet size measurements provide a secure basis from which to manipulate the parameters that influence whether or not spray performance targets will be met. These parameters relate to features of the device and the atomization mechanisms it imposes, and to properties of the formulation, as well as the set-up adopted for spray delivery during product use. When it comes to measuring droplet size distributions, the absolute requirement is for a technique that acquires data at the very high rates needed to capture the fine detail of dynamic spray behavior - in essence, measurement in real time.

For the vast majority of industrially important sprays, laser diffraction particle size analysis delivers the information needed. It can be used equally well to investigate a discrete spray event, as in the case of pharmaceutical nasal sprays, or to profile continuously operating sprays, such as for agricultural spraying or in the application of spray coatings. The practical benefits of such analysis for both types of spray are to inform decision making around the design and set-up of optimized spray systems.

Laser diffraction is suitable for measuring the particle size distribution of liquid and dry powder sprays and aerosols. Using this technique particle size is determined from the scattering pattern produced as particles pass through a collimated laser beam. Small particles scatter light at wide angles while larger particles scatter at narrow angles. Laser diffraction analyzers measure the intensity of light scattered at different angles. From this information the complete particle size distribution can be calculated, through the application of the Mie theory.

Several features of laser diffraction define its value for spray characterization. The first is that data acquisition is very rapid, with a full droplet size distribution captured every 0.1 ms. This allows real-time monitoring of the changes in droplet size that occur during even the most rapid spray events, during fuel injection in an engine for example. The second is the measurement range of the laser diffraction instrumentation, which for sprays typically spans 0.1 to 2000 microns. This relatively wide range compared to other techniques means that both dispersion and coalescence can be comprehensively characterized, over a wide range of conditions, even where this gives rise to a substantial change of particle size in a single event spray event.

Finally, one very practical benefit of laser diffraction is that the laser source and light detectors that make up the instrumentation can be flexibly configured, and indeed positioned some way apart. This eases measurement across broad spray plumes, as in the spray coating and agrochemical applications, where there is also a requirement for measurement as a function of distance from the spray source. Appropriate positioning of the detector also helps to keep optics clean and reduce the workload associated with routine spray measurement.

The following case studies show how different applications draw variously on these features, and the ability of laser diffraction to deliver data for each application.

In engine manufacture, optimizing the injection set-up is a key step to developing products that efficiently deliver the necessary power. Both the rate and efficiency of fuel combustion are related to the size of droplets released from the fuel injector, so optimal design is central to engine performance. Advances in fuel technology, which include the use of higher viscosity biofuels, bring new challenges when designing fuel injection systems, sharpening the focus on effective spray characterization.

Once fuel is released from an injection nozzle within an engine, combustion efficiency is determined by droplet size. Smaller droplets vaporize more quickly than larger ones, so generally enable more rapid and efficient combustion. Larger droplets, however, facilitate better penetration of the spray into the engine's cylinder head. Getting injector design right for any given fuel is essential for efficient long term operation. Fuel injection takes place over the shortest of timescales with a typical injection time of just 0.2 to 10 ms, so gathering relevant data for this application is extremely demanding in terms of measurement rate.

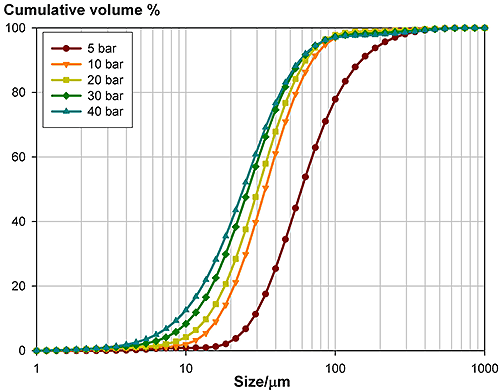

Traditionally the requirement for high data acquisition speeds has been a barrier to research in this area. However, modern laser diffraction spray systems that measure at up to 10 KHz enable the profiling of very rapid spray events. Figure 1 shows data acquired using the Spraytec system (Malvern Instruments) during an investigation of the effect of pressure, across the range 5 to 40 bar, on the droplet size produced by a fuel injection system. This in turn relates to the changes in droplet size which may occur when more power is demanded during engine use.

Twenty-five injection events were characterized at each pressure, yielding a total of 7000 records per experiment. By averaging the data from each event to produce a single cumulative size distribution for each experiment, it is possible to confirm the extent to which droplet size decreases as injection pressure is raised (see figure 1).

|

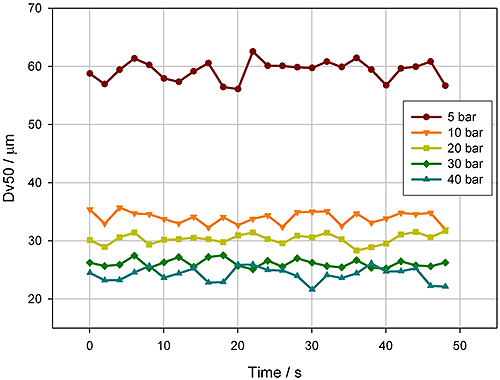

These data are clearly useful in developing an injector set-up that will deliver the droplet size required for clean and efficient combustion, but in engine applications consistency is also critical. By assessing the variability in Dv50 at each pressure, from the 25 sets of data produced under each set of conditions, it is possible to make a judgment about the reproducibility of atomization and the associated consistency of engine performance (see figure 2).

|

Figure 2 shows droplet size variability increases at low pressures. In general, increasing pressure leads to a more reproducible and more consistent atomization process. However, the variability at 40 bar pressure is, in this case, slightly higher than at 30 bar pressure. This may be attributable to degradation of the spray profile, resulting from the onset of cavitation within the nozzle.

In the development and manufacture of nasal sprays, droplet size is controlled to ensure efficient drug delivery and to manage bioavailability. If the droplets are too small - below approximately 10 microns - they risk being drawn through the nasal passages into the lungs. Conversely, relatively large droplets may be trapped in the nostrils and simply flow back out of the nose. This creates an imperative to engineer the product to deliver droplets of the required size, typically in the 20 to 120 microns range. Droplet size data form part of the regulatory submission for both new and generic products. Like fuel injection sprays, nasal spray plumes are relatively narrow, making characterization using laser diffraction easy. However the timescale of the spray event is considerably longer, in excess of 100 ms.

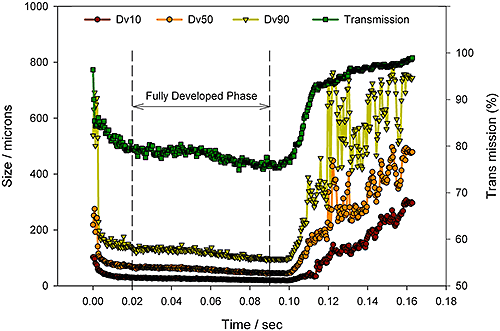

Figure 3 shows droplet size distribution data for a nasal spray, measured using a laser diffraction system. The data obtained are typical of what is observed when a spray pump or aerosol is actuated. The timescale of the spray event is 160 ms and three discrete phases are clearly observed, via droplet size and droplet concentration data.

|

Transmission, shown by the green line in figure 3, is a measure of the change in intensity of the laser after it has passed through the sample, and therefore indicates spray density or droplet concentration. This highlights an advantage of laser diffraction, which is that it measures both droplet size and concentration, helping to elucidate atomization dynamics.

Detailed observation of the atomization provided in figure 3 reveals three discrete phases in the delivery process: formation; a fully developed/stable phase; and dissipation. Initially, during the formation phase, flow through the pump is low but droplet concentration builds rapidly as the pump is primed, evidenced by the sharp fall in the measured transmission. During this phase, droplet size decreases sharply as flow through the pump reaches a maximum steady rate, leading on to the stable, fully developed phase. This phase is the one of most interest since the bulk of the spray delivery occurs under these conditions. The end of the spray event is marked by an increase in droplet size and a marked fall off in droplet concentration as the metering chamber of the device empties.

Here laser diffraction data provide the information needed to understand the dynamics and effectiveness of the atomization process and to compare the performance of different nasal sprays in terms of the droplet size at which the bulk of the drug formulation will be delivered. Such studies enable systematic investigation of the impact of the characteristics of the device, such as pump mechanism and actuator geometry, and of formulation properties such as viscosity, to scope the design space for an innovator or generic. Furthermore they support the demonstration of bioequivalence, which is closely correlated with droplet size, for regulatory submissions in line with FDA guidance.

In the field of paints and coatings, droplet size has an impact on both the aesthetics and performance of the finish. The final coating on a piece of furniture, for example, not only affects product durability but also contributes to customer appeal. Taking steps to optimize the coating process through spray analysis can therefore make an important contribution to a product's perceived, and actual, value. Furthermore, controlling droplet size contributes significantly to overall process efficiency, by shortening drying times for example and reducing the need for costly re-processing. Additionally, careful choice of coatings and the attainment of real control over the application process help minimize the environmental impact of coatings materials through decreasing over-spraying and waste.

When it comes to optimizing systems for delivering surface spray coatings, the quality of the final finish and transfer efficiency (TE) are defining factors. Here the application is continuous spraying, rather than discrete spray events, so although the droplet size is similar to, for example, nasal sprays, the experimental drive is quite different. The aim is to provide data to optimize a closely controlled, continuously operating industrial set-up. Two of the most frequently manipulated variables are fluid pressure and the distance between the spray nozzle and the substrate. In an experimental study a Spraytec system (Malvern Instruments, Malvern, UK) was used to characterize the impact of these parameters on the size of waterborne coating droplets produced by an airless spray nozzle.

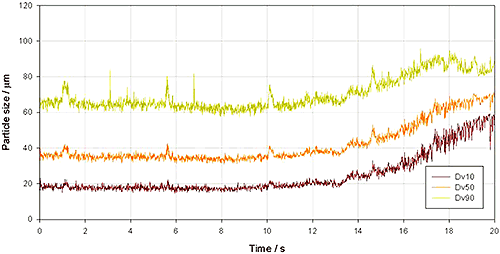

Spray coating systems have wide spray geometries designed to deliver quick and even coverage, so an initial set of measurements was made to investigate the consistency of droplet size across the spray fan (see figure 4).

|

These data were gathered via a vertical traverse of the spray so the time axis translates into distance from the center of the fan. Droplet size is larger towards the edge of the spray (median droplet size 44 µm) than in the center where the median droplet size is 34 µm. Such variations in droplet size can have a marked effect on the finish obtained, but this is easily addressed by moving the spray back and forth across the substrate to ensure that all areas are evenly coated with droplets of a similar size.

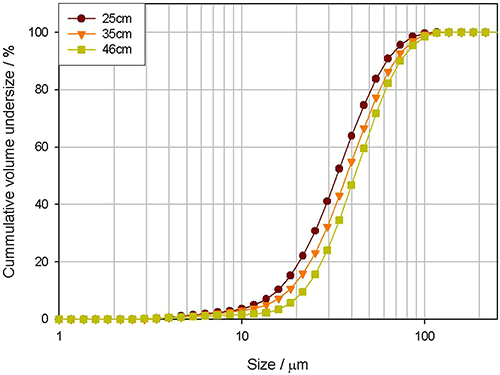

To investigate how droplet size varies when the distance between the spray and the substrate is changed, a further series of measurements was made. Average droplet size distributions were measured at the center of the spray at a distance of 25, 35 and 46 cm (see figure 5). These results show that median droplet size increases as the nozzle is moved further away from the target site, in this case from 33 µm to 41 µm over the distance range covered. This can be attributed to droplet coalescence within the spray fan.

|

|

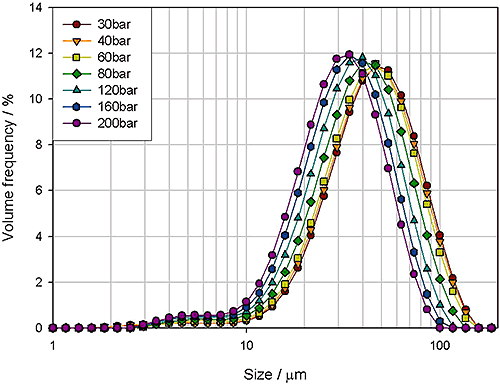

Figure 6 shows a final set of data measured to assess the impact of fluid pressure, an alternative variable that can be easily adjusted by the operator. Again measurements were made at the center of the spray fan, this time as fluid pressure was increased from 30 to 200 bar. These data indicate a significant decrease in droplet size which falls from 42 µm at 30 bar to 28 µm at 200 bar.

The results of these three trials exemplify how, given a target droplet size, settings can be determined for an industrial spraying system to ensure the consistent application of a high quality coating. The ability of laser diffraction to measure particles distributed across wide spray plumes during continuous spray processes is key in enabling characterization of these spray systems.

The agricultural industry faces a dual incentive for droplet control: to maximize delivery efficiency and to meet legislative and environmental constraints. Here, droplet size defines the efficacy of delivery and is tailored to ensure deposition at different target sites depending on the product being applied. However, it also influences the extent of spray drift - the movement of an agricultural spray into any area other than the intended target. Spray drift can be damaging to sensitive, untargeted crops and has further potentially hazardous implications for residential districts or watercourses. Studies of droplet size enable the specification of a spray delivery regime best suited to both the crop and the surrounding environment.

With respect to the practicalities of applying agrochemicals, farmers can select the type of spray atomization nozzle they need and can adjust the pressure used to force liquid through the nozzle in order to control the droplet size. To help in selecting the correct nozzle type and spray conditions, the British Crop Protection Council (BCPC) has produced a classification scheme for agricultural nozzles based on a set of different droplet size ranges, these being Very Fine, Fine, Medium, Coarse and Extra Coarse droplets. Picking the most appropriate nozzle class depends on the target species and the risk and impact of spray drift. As part of this classification scheme, the BCPC has also selected standard nozzles for each class, against which unclassified nozzles can be assessed.

Once again this is an application involving continuous spraying and the need to optimize a spraying set up, so there are parallels with the previous coating study. However the Dv50 of droplets for this application is much larger, and there is a simultaneous requirement to precisely quantify the levels of fines present, to assess the likelihood of drift. The wide size range which can be measured using laser diffraction is therefore important to this application. The focus for investigation is scoping the performance of specific nozzles, under a range of possible on-farm operating conditions, to ensure appropriate selection. To demonstrate the application of laser diffraction particle sizing, five standard British Crop Protection Council (BCPC) nozzles (BCPC01, BCPC03, BCPC06, BCPC08 and BCPC10) at the boundaries of the different spray classes were characterized using the Spraytec system. The aim of the study was to establish baseline droplet size data to define the BCPC classification grid, in order to assign a classification to other non-standard nozzles operated under various conditions.

Each spray was analyzed as it traversed the measurement zone of the instrument permitting the determination of droplet size as a function of position within the spray plume. The cumulative volume-based droplet size distribution for the entire spray plume was then calculated by averaging all the data obtained during the traverse, weighted according to the concentration of the spray at each measurement point. Droplet size data were summarized in terms of volumetric median diameter values (Dv50), the droplet size below which 50% of the population lies on a volumetric basis.

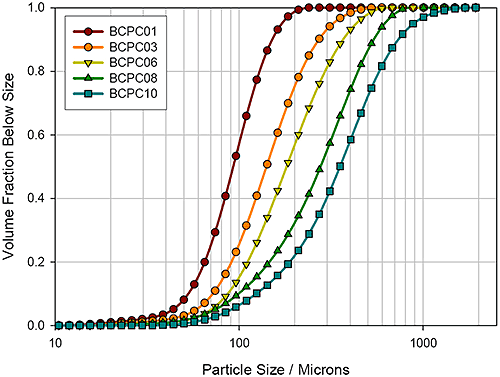

Figure 7 shows data for the standard BCPC boundary nozzles, illustrating the expected increase in particle size at higher classification numbers.

|

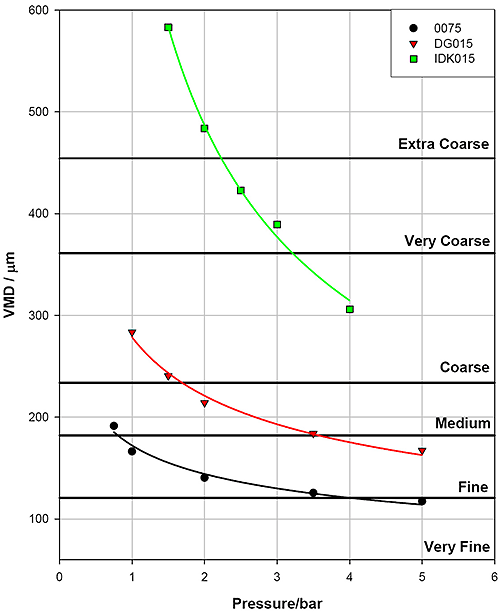

The Dv50 data from these tests were used to define the BCPC classification grid, which ranges from Very Fine, a droplet size (Dv50) of less than 120 μm, through to Extra Coarse, a droplet size greater than 450 μm (see figure 8). Three flat-fan unclassified nozzles (0075, DG015 and IDK015) were then analyzed in an exactly analogous way to assess their performance relative to the defined BCPC classifications. Particle size distributions were measured for each nozzle at a range of liquid pressures between 0.75 and 5 bar (see figure 8).

The data obtained for these three flat nozzles illustrate how droplet size information can be used to classify nozzle designs and provide guidance for selecting both nozzle and operating pressure for a specific crop in a specific location.

Nozzle 0075 was found to produce droplets in the size range 191 µm to 117 µm as pressure was varied from 0.75 bar up to 5 bar, with droplet size lying in the Fine classification between 1 and 4 bar. Fine sprays maximize droplet surface area and will typically give good levels of pest control, although the potential for spray drift is likely to rule out their use under most field conditions.

Nozzle DG015 produces droplets that vary from 283 µm at 1 bar, to 167 µm at 5 bar, thus covering the Medium spray classification in the range of 1.5 to 3.5 bar. This droplet size range is ideally suited to the treatment of broadleaf weeds.

|

The third nozzle IDK015, on the other hand, generated a droplet size that varied between 583 µm at 1.5 bar and 306 µm at 4 bar, producing the Very or Extra Coarse droplets that offer acceptable efficacy for only a limited number of pesticides. This nozzle does, however, minimize the potential for spray drift.

A number of industries share the need to control the droplet size of sprays and aerosols in order to ensure successful delivery of a product, whether a drug to a patient, a coating to a substrate, an agrochemical to a plant or fuel in an engine. To meet droplet size specifications precisely, formulators and developers may alter the physical properties of the formulation, change specific features of the nozzle geometry, or adjust the set-up applied during use, but in each case informed choices as to the best course of action rely on the availability of appropriate data.

The rapid data acquisition associated with laser diffraction particle size analysis enables real-time tracking of the evolution of droplet size, even for the fastest spray events. The results provide insight into the dynamics of spray behavior and, most importantly, deliver a firm foundation of understanding that supports the swift identification of optimal operating parameters. As these case studies demonstrate, no matter what the application, laser diffraction particle size measurements support the development of efficient spray systems to meet demanding industry specifications.