DDCOM

Ultra-fast, bottom surface measuring crystal orientation in a compact package

Features include

- Benchtop device

- Higher throughput due to no height alignment

Fast, accurate crystal orientation

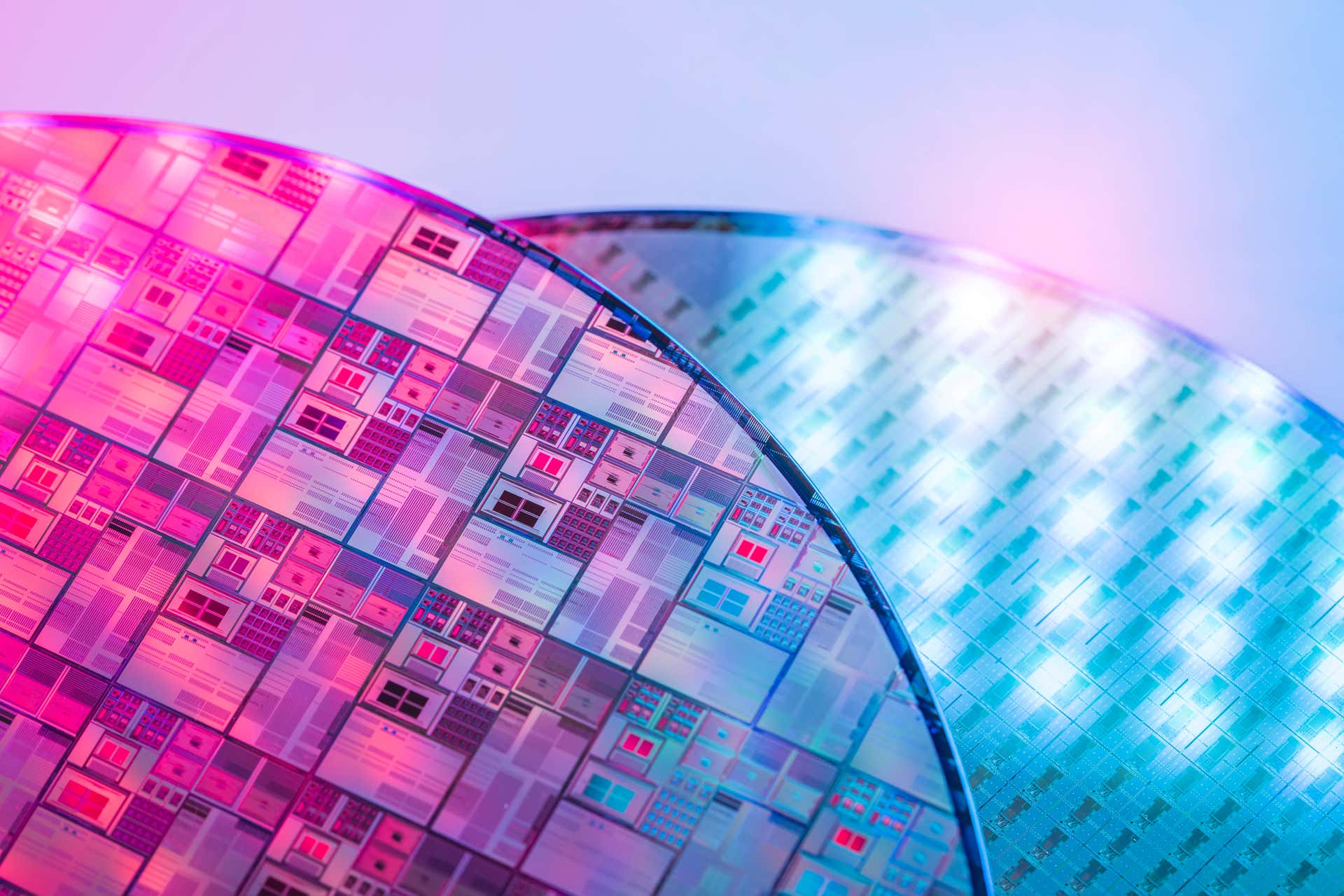

A crystal is a repeating pattern of atoms which means that what we see from the point-of-view of an electron/photon going into this crystal, will depend on the angle we are looking into this crystal. The view could be a channel pointing all the way through the crystal or just the top three layers of the material, therefore the material properties can be quite different depending on the angle. A good control of the material properties requires a good control of the crystal orientation.

It is an important process in ion implantation, lithography, epitaxy but also for example when making a laser or optical components.

The Crystal Orientation range is based on Azimuthal scan, a smart geometrical measurement technique to orient the crystal. That means that we can find not only the tilt of the main axis, but also all in-plain directions in as fast as 10 seconds. The instruments can measure almost any shape as long as it is a single crystal, such as wafers, ingots, boules, pucks etc.

Well designed for industrial applications such as single crystal or wafer manufacturers, research purposes but also for quality control of the wafers and other devices,

Our highly precise Crystal Orientation systems offer simple and quick crystal orientation measurements, ensuring the desired properties are there for the next processing steps.

Ultra-fast, bottom surface measuring crystal orientation in a compact package

Features include

Ultra-fast, flexible, top surface measuring crystal orientation in a compact package

Features include

Fully automated vertical three-axis X-ray diffractometer for ultra-fast crystal orientation

Features include

Fast, precise and fully equipped solution for wafer orientation and sorting

Features include

Integratable wafer orientation solution

Features include

Fully automated in-line orientation and handling of ingots, boules, and pucks

Features include