Overview

XRD-OEM brings the crystal orientation metrology to the next level. Built to withstand the challenging conditions of grinding and sawing, this X-Ray diffraction system offers seamless integration into any processing line while ensuring the highest precision and speed.

Features and Benefits

Compact and connected

Designed to integrate effortlessly into any processing line, XRD-OEM enables a streamlined, efficient and continuous orientation measurement without transferring samples between instruments.

Robust

Built for durability and resilience, XRD-OEM can be deployed into any harsh environment such as grinding and sawing processes, and it will stay reliable while ensuring high productivity and throughput.

Fast and precise

With measurements completed in just as few as 10 seconds per sample, XRD-OEM guarantees high production rates while not compromising its precision, with a standard deviation of less than 0,003o due to the usage of the Azimuthal Scan method.

Convenient

XRD-OEM is capable of detecting the geometrical reference, whether that is a flat or a notch, an essential feature during the pre-alignment of large ingots before sawing or grinding processes.

It can also determine crystal orientation on both flat surfaces and circumferences for extra versatility.

Key Applications

-

- Production and processing

- XRD-OEM is designed with your busy production environment in mind. As an in-line instrument, it is ready to be integrated into your automated high-throughput setup as an efficient solution for measuring and handling ingots, boules, and panels. Capable of measuring a range of compound semiconductor materials including Si, SiC, GaAs and many more, its air-cooling and compact size make it a powerful and cost-effective addition to your process.

- Ingot pre-alignment before sawing or grinding

- With its accurate pre-alignment capabilities, XRD-OEM enables precise positioning and orientation control before further processing steps.

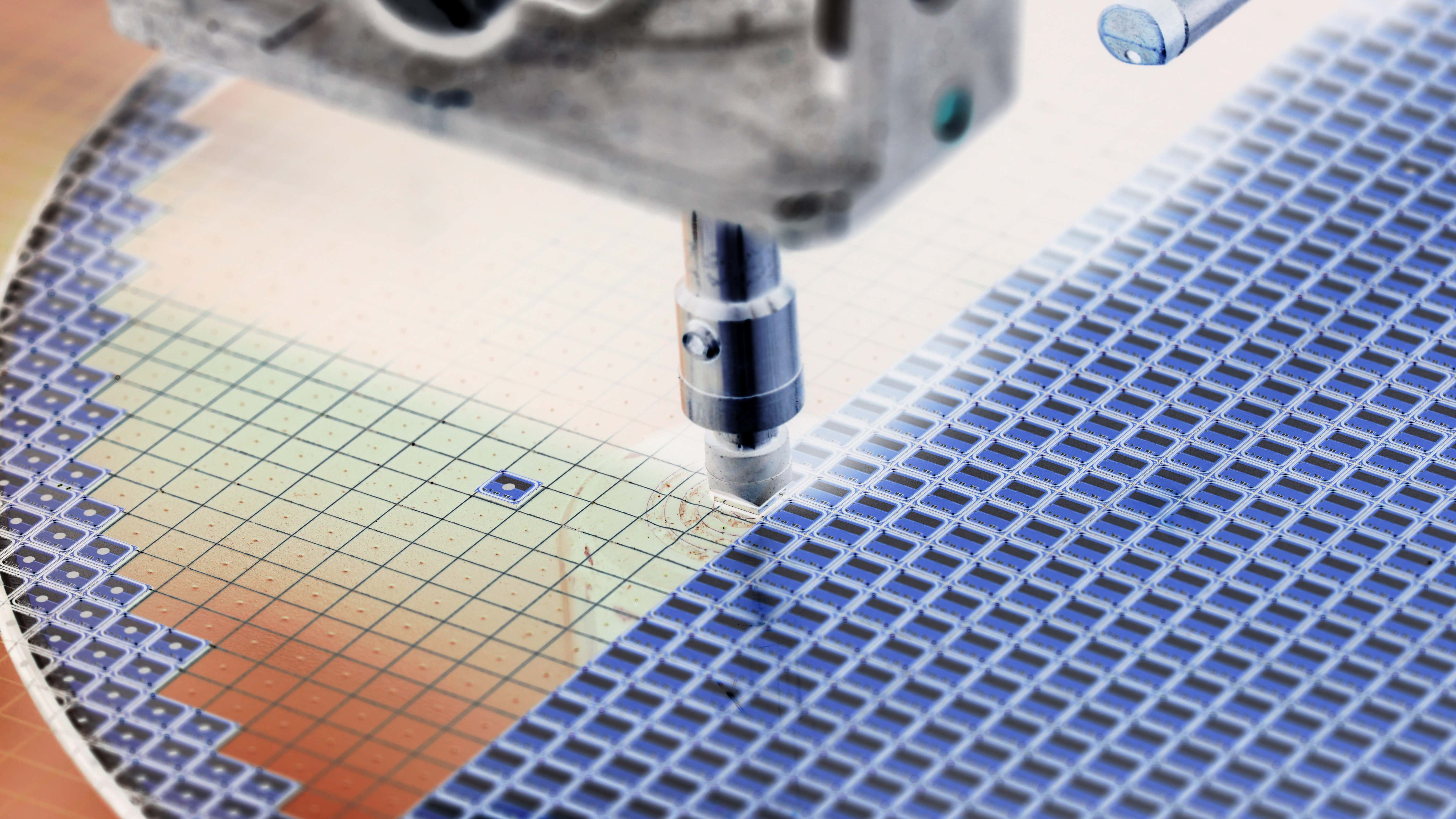

- Quality control

- Rapid orientation measurements are essential in production, and XRD-OEM delivers quality data at speed. By fitting seamlessly into your new or existing automated processes, XRD-OEM helps you to prepare for the automated future of manufacturing today.

Specification

| Notch position | 0.005° |

| Notch depth | 0.005 mm |

| Notch profile angle, typical | < 0.5° |

| Diameter | 0.02 mm |

| Flat position | < 0.03° |

| Flat length | < 0.3 mm |

Support

Support services

- Phone and remote support

- Preventive maintenance and checkups

- Flexible Customer Care Agreements

- Performance certificates

- Hardware and software upgrades

- Local and global support

Expertise

- Turnkey solutions for elemental and structural semiconductor metrology

- Automation and consultancy

- Training and education