This note demonstrates the excellent capability of the Metals editions of the Zetium spectrometer analysis of precious metals in automotive catalysts. The system is precise, accurate and repeatable offering a viable alternative to fire assay for many types of precious metals analysis.

Due to their high activity, selectivity and recyclability, precious metal chemicals are often the first choice as heterogeneous catalysts for chemical reactions in automotive catalysts. Accurate determination of these precious metals (e.g. Pt, Pd, Rh) in catalysts is critical for developers and producers of automotive catalysts as well as those recycling the end products to reclaim these precious metals.

Due to their high activity, selectivity and recyclability, precious metal chemicals are often the first choice as heterogeneous catalysts for chemical reactions in automotive catalysts. Accurate determination of these precious metals (e.g. Pt, Pd, Rh) in catalysts is critical for developers and producers of automotive catalysts as well as those recycling the end products to reclaim these precious metals.

Traditionally, the time-consuming and labor-intensive method of fire assay has been the industry standard because of its excellent accuracy and low limits of detection. However, the time and skill necessary to perform accurate fire assay determinations makes it an expensive type of analysis. By comparison, XRF is a relatively simple, non-destructive and cost-effective method of analysis.

This note demonstrates the excellent capability of the Metals editions of the Zetium spectrometer analysis of precious metals in automotive catalysts. The system is precise, accurate and repeatable offering a viable alternative to fire assay for many types of precious metals analysis.

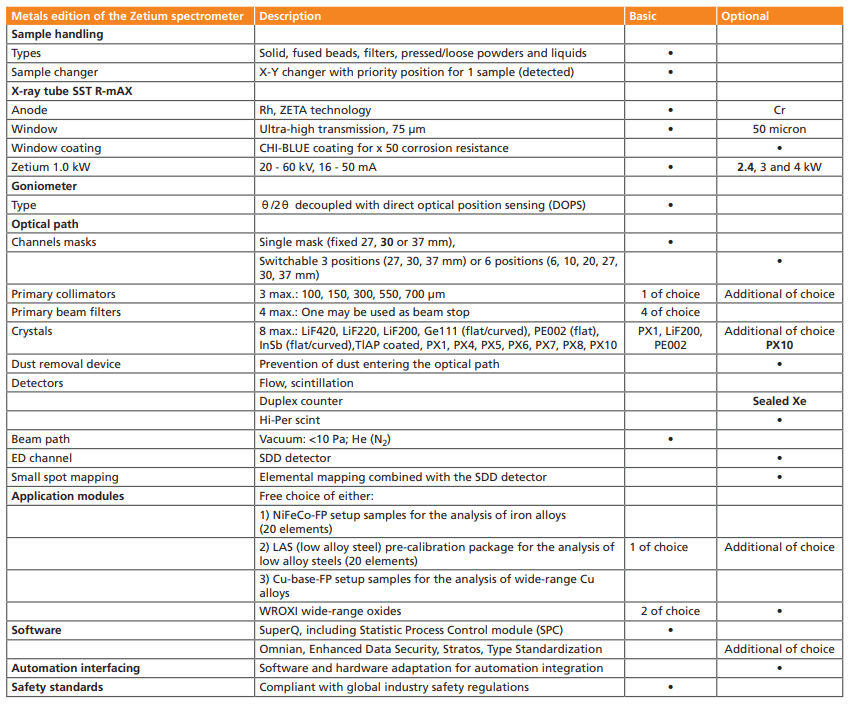

The power settings of the X-ray tube were 50 kV / 48 mA for Ce and La and 60 kV / 40 mA for Pt, Nd, Pd, Rh, Zr and Sr. For analyzing Zr and Sr a collimator of 150 µm spacing was used whereas for all other elements a collimator of 300 µm spacing was used. A PX10 crystal was selected to obtain high intensities for Pd, Rh and Zr. Nd and Ce characteristic X-rays were detected by means of a duplex counter. Background reduction and improvements to peak-to-background ratio were achieved by using different tube filters (brass 100 µm and 300 µm and Al 750 µm). A brass 300 mm is particularly important for analyzing Rh, because it removes the Rh lines from the X-ray tube.

A series of in-house catalyst standards were used to set up the calibrations. The samples were prepared as 35 mm (diameter) and 8 mm thick pressed pellets by mixing 9.6 g of powdered sample with 2.4 g of a copolymer-wax binder and pressing at 20 tons for 30 s in an automatic sample press.

The precision, repeatability and reproducibility of the Metals edition of the Zetium XRF spectrometer is outstanding, not only for short-term measurements but also for longer- term measurements, Table 1. 20 con- secutive measurements of one of the

catalyst samples demonstrate standard deviations of 0.5 % relative at the 350 mg/kg level, e.g. 351.9 ± 1.8 mg/kg Pt. This level of precision is maintained for measurements carried out over a period of ten days, illustrating the long-term stability of this system without re- calibration. This stability is illustrated graphically for Pt and Rh in Figure 1. Table 2 lists the counting times required to obtain an analytical precision of 1% relative for one of the catalyst samples.

Table 1. Analytical precision

Table 2. Counting time for achieving a maximum of 1 rel% precision

The accuracies of the calibrations are presented in Table 3. The calibration RMS value is a statistical comparison (1 sigma) of the certified chemical concentrations of the standards with the concentrations calculated by regression in the calibration procedure. Due to sample heterogeneity and errors in the given concentrations of the standards, higher RMS values are observed for the calibrations than for the precision of the instrument.

Calibration plots for Pd and Rh give a graphic illustration of the accuracy of the method, Figures 2 and 3.

Table 3. Calibration quality

Figure 1. Short- and long-term stability measurements of Pt and Rh in a catalyst standard

Figure 2. Calibration graph for Pd

Figure 3. Calibration graph for Rh

Detection limits for the analytes of interest in typical automotive catalyst matrices are given in Table 4. The lower limit of detection (LLD) is calculated from:

Table 4. Detection limits

Components typeset in bold were present in the spectrometer used to obtain the data in this note.

The results clearly demonstrate that the Metals edition of the Zetium spectrometer is capable of analyzing precious metals in automotive catalysts at mg/kg levels. Measurements are accurate and precise and the method benefits from simple, essentially hazard-free, sample preparation. The stability of the Metals edition of the Zetium spectrometer is such that individual calibrations can be used for months. Time-consuming re-standardizations are unnecessary and the resulting data are highly consistent over time.