Subvisible particles are of increasing interest in industrial and pharmaceutical applications, but they can present a challenge to many particle sizing techniques. Optical imaging can theoretically measure particles that are as small as 0.5 µm with white light illumination. However, there is more to this limit than the illumination wavelength range. Indeed, the quality of images acquired by the system also plays a crucial role to ensure accurate measurements.

There are different circumstances where small particles need to be measured. For example, small particles may be debris from mechanical damage to large particles (such as in abrasives); in this case, it is important to understand the load of these fine particles. A number-based technique performs better than a volume-based technique in this situation because all particles count equally in a distribution so the small particles have an importance on the size distribution that is proportional to their abundance. On the contrary, in a volume-based measurement such as obtained by laser diffraction or light scattering, the small particles have a contribution proportional to their volume.

Another example of important measurements of small particles is the analysis of nanometer-sized particles suspensions, where micron-sized particles are indicative of an aggregation or contamination problem (some biological pharmaceutical formulations are one such example). In this case, the larger particles are important, so it may be possible to use a volume technique to emphasize their presence. If however a count is required, then only a number-based technique can provide this result.

Small subvisible particles, in the size range of 0.5 to 10 µm are also receiving increasing interest, especially in protein formulations due to the potential immunogenic response such large aggregates could cause.

When analyzing small particles by the technique of automated image analysis in applications such as those described above, the quality of the images is key since it directly impacts the reliability of the size and shape measurements. Factors that affect the quality of the image include:

The FPIA-3000 is a flow particle image analysis system which enables image acquisition and particle measurement in the size range 0.8-300 µm.

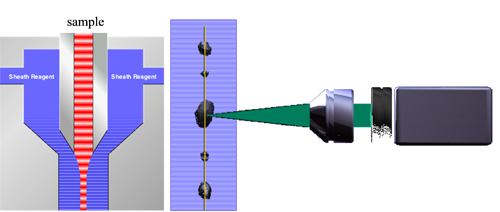

The excellent performance of the FPIA-3000 for the measurement of small particles is due to the combination of a high resolution camera, calibrated and controlled illumination and the controlled sheath flow mechanism. This aligns particles at the focal plane of the imaging camera keeping them in focus by sandwiching a thin (~ 3 µm) flow of the suspension between two 'curtains' of sheath fluid, from which larger particles protrude. Figure 1 illustrates the process. The sheath flow mechanism also means that particles do not come into contact with the cell windows eliminating any contamination or cleaning requirements.

In order to demonstrate the resolution of the FPIA-3000, two different experiments measuring latex spheres were performed.

For both experiments the latex spheres (Duke Scientific Corporation, Palo Alto, CA) were dispersed in distilled water. In order to favor the separation of agglomerated beads,

|

|

|

which are common in this type of product, the sample was subjected to sonication for 30 seconds in the sample chamber prior to automatic injection into the imaging cell.

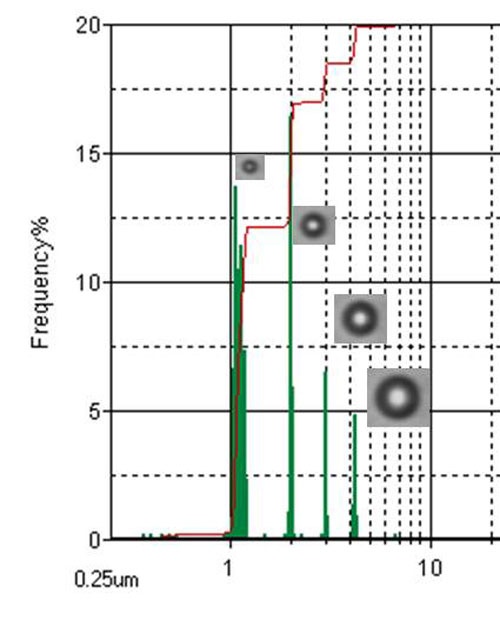

For the first experiment a suspension of a mixture of 1, 2, 3 and 4 µm spheres was prepared.

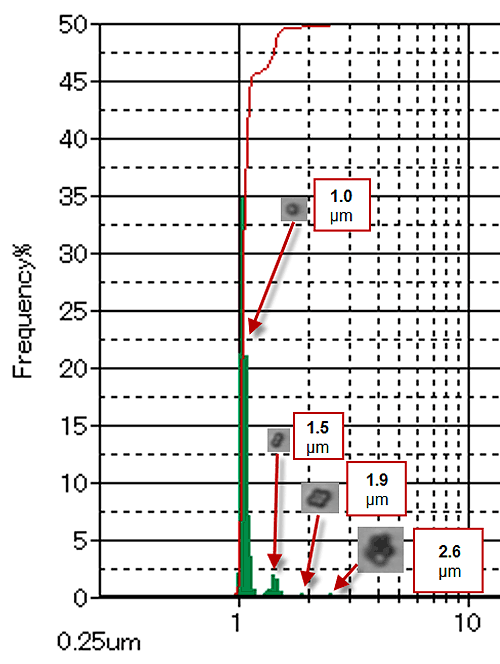

For the second experiment, a suspension contained only the 1 µm spheres was prepared.

For this application the FPIA-3000 was operated in High Power Field mode with a 20X lens giving a total magnification of 40X.

Figure 1 shows the result of the first experiment in terms of a number based Circular Equivalent Diameter size distribution. The selection of the most appropriate magnification means that images are of excellent quality and the four classes are well separated. The 20x magnification used in High Power Field gives a total of 40x and results in a pixel size at the object plane of 0.185 µm. At this magnification, a 1 µm sphere is imaged onto a circle that is 6 pixels in diameter.

Figure 3 shows the result of the second experiment in terms of a volume based Circular Equivalent Diameter size distribution. It indicates that the system is also able to distinguish between doublets, triplets and larger agglomerates of 1 µm particles.

The FPIA-3000 is an excellent tool for measuring small particles. The patented sheath flow in combination with controlled illumination and the use of a high magnification objective ensure that the particles are at the point of focus, consistently illuminated with the correct light intensity and imaged at high resolution leading to reliable results.