Acrylonitrile-butadiene copolymers (NBR) are more commonly known as nitrile rubbers or Buna-N. Some trade names include Nipol, Krynac and Europrene. Copolymers of an unsaturated nitrile and diene, they are used widely for adhesive compounding, where resistance to oil, fuel and grease is required. Gloves for examination, cleaning and disposable lab supplies are made of various grades of NBR. The chemical resistance to chemicals like ketones is dictated by the composition of the copolymers as well as the molecular weights of NBR. Furthermore polymer cross-linking and branching are affecting the macroscopic properties of NBR like flexibility and puncture resistance, a key attribute for gloves. In this communication, three samples of NBR are studied by triple detection gel permeation chromatography (TD-GPC).

The triple detector system is ideal for analysis of rubbers because it directly detects changes in polymer structure, which affect the polymer's performance. Conventional methods detect only differences in hydrodynamic size. Concentration distribution is calculated through the refractometer, viscosity through the Wheatstone bridge viscometer, and absolute molecular weight directly from the light scattering detector.

Tetrahydrofuran (THF) stabilized with 250 ppm of BHT was used to dissolve the NBR samples and as the eluent for the GPC. The pump flow rate was constant at 1 ml/min. The injection volume was 100 μL and the concentration injected was about 2% NBR. The columns used were 10 μm mixed bed SDVB.

|

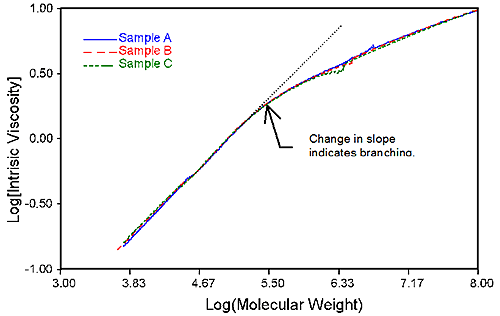

Samples A, B, and C all have the same dn/dc, indicating they are all similar in composition. This is clearly illustrated by overlaying each Mark-Houwink plot, figure 1, which is the log of intrinsic viscosity as a function of the log of molecular weight. All three samples have the same density to molecular weight relationship. Note the change in slope around log (molecular weight) = 5.50, or molecular weight of 315,000 g/mol. From this, it can be concluded that there is polymer branching at the higher molecular weight range of the rubber samples.

|

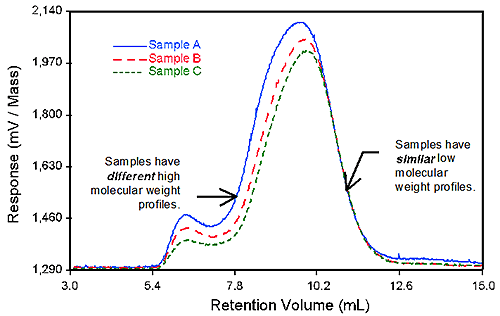

Figure 2 presents the light scattering overlay if the 3 NBR samples. The high molecular weight shoulder shown clearly by the detector plays an important role in the determination of sample differences resulting either from aggregation or cross-linking. The overlay of the light scattering chromatograms (normalized for concentration) gives a direct idea of the presence of sample that has a very high molecular weight.

|

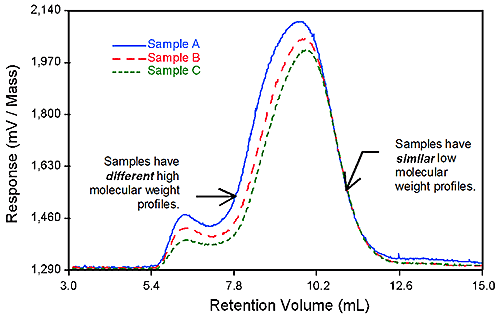

Figure 3 overlays the viscometer signals for the 3 NBR samples. The samples are also ranked easily by the overlay of the normalized viscosity chromatograms. The viscosity detector provides extra insight into the nature of the very high molecular weight shoulder. Since the viscometer does not respond strongly to the shoulder, it has a very high density. This indicates the presence of branching or cross-linked material.

Through TD-GPC, much information can be determined about a polymer. The triple detector system can determine the hydrodynamic radius reliably and accurately down to less than 1 nm . Also, intrinsic viscosity values are the same as those as would be obtained from the creation of a Huggins' plot with U-tube analysis. The light scattering detector measured the absolute molecular weight of the sample. Polydispersities and Mark-Houwink coefficients are also available using the triple detection method.