Metal organic frameworks (MOFs)

MOF characterization solutions to help you build robust structures

MOF characterization solutions to help you build robust structures

Metal organic frameworks (MOFs) are hybrid crystal covalent structures created by reacting organic molecules with metal ions. Not only are they more durable than organic crystals, but because of their nano-scale interconnected voids, they have unrivaled potential for trapping, storing, and catalyzing ions and molecules.

Thanks to these abilities, MOFs can add significant value in several applications, including gas storage and separation, liquid separation and purification, electrochemical energy storage, catalysis, or drug delivery. They can also be used in gas sensor devices that measure and respond to this capture process.

To take full advantage of MOFs’ potential, you need to be able to adjust their key characteristics and local environment (such as the electric field, temperature, pressure, or chemistry). Specifically, material characterization and optimization enable you to tailor the molecules or ions you attract, control how quickly the MOF traps or releases them, and ensure that it does this effectively. In this way, you can ensure that your MOF delivers robust, consistently processable end-products.

MOFs’ crystal structures give them their collection abilities. And, by tailoring the MOF’s constituent molecules and how it is synthesized, you can optimize the size, connectivity, and binding affinity of the crystals’ voids to attract specific molecules or ions. To do this, you need a strong understanding of how the crystalline lattice structure interacts with other molecular and ionic species, and how variations in the host environment affect this structure.

Understanding particle size and morphology is also important: optimizing these characteristics can maximize your MOF’s performance. Specifically, the particles’ total surface area determines how effectively gas or liquid can flow through and how quickly the MOF can trap or release molecules or ions. For the best end-product, MOF particles must remain a constant size, intact, and not agglomerated, and the powder’s flow and packing must be controlled.

Next to this, monitoring the elemental concentration of a MOF’s carrier liquid can help ensure that the MOF harvests and releases ions effectively.

Finally, when MOFs are formulated in synthetic nanoparticle form, the surfaces of these synthetic nanoparticles can be modified. This enables the nanoparticles to access cells and therefore to carry a wide range of active and targeted pharmaceutical drugs. Understanding the nanoparticles’ hydrodynamic behavior is essential for success with this kind of MOF application.

X-ray diffraction (XRD) enables you to measure and verify your MOF’s crystal structure – and our Empyrean and Aeris X-ray diffractometers provide the highest-quality powder diffraction data. Aeris can obtain scans in just five minutes, and both instruments provide excellent resolution and sensitivity for the finest details. Additionally, the ultra-sensitive microcalorimetry of our MicroCal PEAQ-ITC provides direct measurements of your structure’s binding affinity, stoichiometry, enthalpy, and entropy.

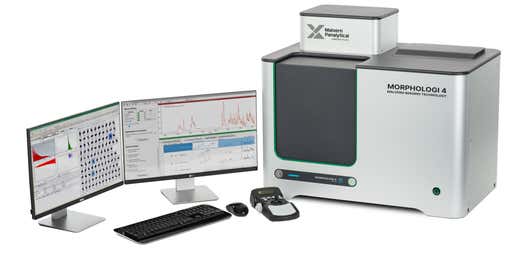

For particle sizing, our Mastersizer laser diffraction particle sizer is the solution – and its versatility means you can create the best setup for consistent results. When it comes to particle morphology, Morphologi 4 can generate a full set of size and shape results for up to 500,000 particles in just 30 minutes. And, with Morphologi 4-ID, you can return to any individual particle for more detailed analysis, such as Raman spectroscopy.

When it comes to analyzing MOF nanoparticles in solution, Dynamic Light Scattering (DLS) and Electrophoretic Light Scattering (ELS) are ideal for measuring particle size and analyzing particle drift for Zeta potential, respectively. Our Zetasizer Advance range supports both techniques, and the Nanosight Pro complements these measurements with real-time imaging of particle movement, including tracking analysis for both sizing and concentration.

In addition, our X-ray fluorescence (XRF) instruments, such as Epsilon and Zetium, can help you avoid impurities and track species uptake or expulsion by analyzing the chemical composition of your MOF sample or its carrier solution. Or, with our sample preparation equipment, you can also make solutions for ICP chemical analysis.

With Malvern Panalytical, you can also rely on the expertise of our application scientists. Whatever the instrument, they’ll show you how to get the most out of it through tailored training. And our regional customer support teams are only ever a call away. Whether you need a quick explanation, a full service contract, or anything in between, we’re here for you.

Let us help you get the most from your MOFs – contact us today.