What is the value of NIR & full range spectrometers and how is chemometrics (multivariate analysis) used to develop quantitative calibrations for beer brewing and ethanol production properties.

“The brewing process includes several steps: malting, milling, mashing, lautering, boiling, fermenting, conditioning, filtering and packaging. The fermentation step is critical to the final beer quality because a multitude of factors (e.g. temperature, pH, sugar composition, yeast type) can affect a large number of quality parameters.” (Grassi et al., 2013)

The value of NIR & full range spectrometers:

- “The analysis of the spectral response of vegetation through remote sensing could be a valid means to rapidly investigate and define overall plant health and nutritional status.” (Fluvià, 2015)

- NIR measurements have been found useful for plant breeding and monitoring of crop ripening screening purposes (Halsey, 1987)

- NIR can be used for the quality control testing of raw materials (barley, malt, hop, yeast), intermediates, and finished product (Valeria et al., 2012)

- Conventional NIR analysis, on ground samples, has been applied to hops for the analysis of moisture, α-acids, β-acids, hop oil and the prediction of hop storage index (Halsey, 1987)

- Ethanol can be produced from many different starch sources including corn, wheat, barley or potatoes; NIR technology has made it possible to directly measure composition of these raw ingredients and to predict ethanol yield (Fluvià, 2015)

- NIR is a useful tool to measure the composition of distillers grain products used for animal feeds (ASD Inc., 2009)

- The use of NIR has indicated that alcoholic beer samples could be clearly discriminated with respect to ageing stage (Ghasemi-Varnamkhasti et al., 2012

Use of chemometrics (multivariate analysis) to develop quantitative calibrations for beer brewing & ethanol production properties:

- Multivariate calibrations can be created to provide a variety of compositional or processing characteristics

- Real time quantitative analysis using calibrations configured to work with the ASD LabSpec analyzer (GRAMS IQ; The Unscrambler®)

- Use regression analysis to correlate various laboratory methods to NIR reflectance

- Calibrations can be created for all parts of the fermentation process, such as: moisture, protein and starch content (grain receipt), malt quality and protein (malting), total carbohydrates, fermentable carbohydrates, wort parameters (mashing), soluble sugars, acid content (fermentation), sulfur content, moisture, protein, fiber (production of by-products for animal feed)

- Make multiple analyses with one measurement.

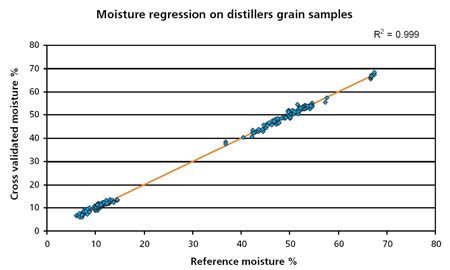

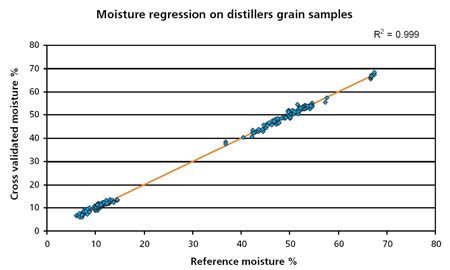

Figure 1. Distillers Grain Moisture calibration results. Validation of the moisture model with the independent test set of 55 samples produced an RSQ of 0.999 and SEP of 0.96 (ASD Inc., 2009)

The solution

ASD spectrometers have high signal-to-noise design for optimal sensitivity and speed, combined with a spectral range of 350- 2500 nm, they are suitable for measurement of a variety of compositional and important processing parameters.

ASD instruments are a practical solution for the determination of beer brewing & ethanol production component properties.

- LabSpec 4 offers laboratory-grade performance in a ruggedized, portable design suitable for benchtop analysis or transport to the sample location. Used for quantitative applications.

- Muglight designed for analysis of raw materials requiring reflectance and absorbance measurements.

- Turntable for analysis of irregularly shaped or non-homogeneous samples. Ideal for obtaining a highly accurate average.

Ideal for beer brewing & ethanol production applications:

- Portable solution; suitable for lab and at-line

- Non-invasive and Non-destructive

- Simple, rapid and cost effective real-time measurement (data and analysis in the field)

- Little or no sample preparation

References

ASD Inc. (2009). Distillers Grain Sulfur and Moisture Modeled using LabSpec 5000. Boulder, CO: Dan Shiley.

Fluvià, S. (2015, October 26). NIR techniques and chemometric data analysis applied to food adulteration detection. Retrieved from http://upcommons.upc.edu/bitstream/handle/2117/78402/memoria.pdf

Ghasemi-Varnamkhasti, M.; Mohtasebi, S.; Rodriguez-Mendez, M.; Gomes, A.; Araújo, M.; Galvão, R. (2012), Screening analysis of beer ageing using near infrared spectroscopy and the Successive Projections Algorithm for variable selection. Talanta(89), 286-291. doi: 10.1016/j.talanta.2011.12.030

Grassi, S.; Amigo, J M.; Lyndgaard, C.B.; Vigentini, I.; Casiraghi, E. (2013, June). Monitoring beer fermentation by using FT-NIR spectroscopy. Paper presented at NIR2013 Proceedings; A1-Agriculture and Environment, La Grande-Motte, France (pp. 79-81).

Halsey, S. (1987). Near infrared reflectance analysis of whole hop cones. Journal of the Institute of Brewing(93), 399-404. doi: 10.1002/j.2050-0416.1987.tb04526.x

Valeria, S; Marconi, O.; Perretti, G. (2012). Near-infrared Spectroscopy in the Brewing Industry. Critical Reviews in Food Science and Nutrition(55),1771-1791. doi: 10.1080/10408398.2012.726659