The performance of a drilling mud, or fluid, is affected by its particle size. The ideal particle size depends on the geological formation and the function required of the mud. This note describes how laser diffraction can analyze different mud types.

The performance of a drilling mud, or fluid, is affected by its particle size. The ideal size depends on the geological formation and the exact function required of the mud. Rapid access to the mud particle size allows drilling muds to be customized during production.

Drilling muds are liquids circulated through the wellbore during drilling to provide multiple functions, including:

Drilling muds can be either water-based or oil-based. Water-based muds are relatively inexpensive and more environmentally friendly, but can be difficult to formulate and costly to maintain. Oil-based muds are easier to formulate and maintain, but are more expensive to produce and pose a greater pollution risk.

Drilling mud formulations may contain the following components.

Water-based muds may also contain additives, such as starches and polymers, to reduce fluid loss.

The geology of the formation will determine the optimum particle size of the drilling mud. The particle size should be small enough to form bridges across the pores in the formation, preventing fluid and pressure losses. However, the particle size must not be too small so that the mud itself can penetrate into the formation.

There has been a significant amount of research into exactly how to correlate mud particle size to formation pore size. Some of the particle size recommendations are summarized below:

The particle size of a weighting agent affects the ability of a mud to protect the formation, as well as the stability of the mud. If the particle size is too coarse then particles can settle out and damage equipment. However, too many fines can lead to insufficient weighting and formation damage.

Barite is commonly used as a weighting agent in both water-based and oil-based muds. The American Petroleum Institute (API) has two specifications relating to barite particle size: the percentage of material larger than 75 micron should be minimized, and the percentage of material smaller than 6 micron should be less than 30%.

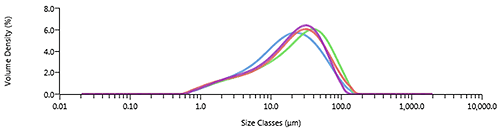

|

| Record number | Dx 10 (µm) | Dx 50 (µm) | Dx 90 (µm) | Result below 6 µm (%) | Result above 75 µm (%)

|

|---|---|---|---|---|---|

| 9 | 3.236 | 17.543 | 57.833 | 19.55 | 4.94 |

| 10 | 3.301 | 24.478 | 73.337 | 17.59 | 9.39 |

| 11 | 3.008 | 21.698 | 66.546 | 18.46 | 7.31 |

| 12 | 3.140 | 20.556 | 57.840 | 18.65 | 3.97 |

The particle size distributions of four Barite samples from different suppliers are shown in Figure 1. As the materials have been developed to fulfill the same function the samples have similar size distributions. All of the samples meet the API specifications with less than 20% of the material below 6 micron and between 3% and 10% larger than 75 micron.

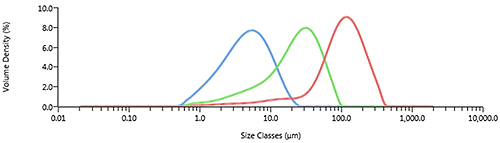

To achieve bridging over the pores in a formation the particle size of the bridging material must match the pore size of the formation. Calcium carbonate is commonly used as a bridging material (it can also be used as a weighting material) and a range of different particle size grades are available form coarse (median size larger than 100 micron) to ultra-fine (median size smaller than 10 microns) so that the appropriate grade can be used for each formation.

|

The particle size distributions of a fine, medium and coarse grade of calcium carbonate are shown in Figure 2, with median particle sizes of 4.5um, 23.5um and 105.5um respectively.

|

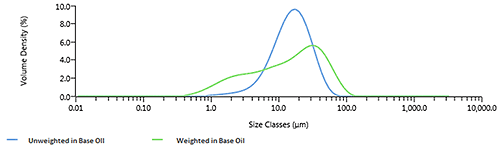

Figure 3 shows the particle size distributions for a mud containing mainly bridging agent, un-weighted, and a mud with a weighting agent added, such as barite. The weighted mud has a much broader size distribution which will increase the maximum packing fraction of the mud, increasing its weight and changing its rheological properties.

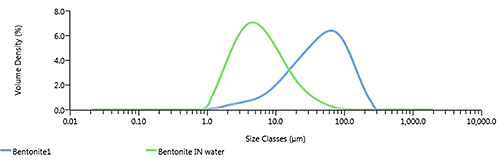

Achieving meaningful and reproducible results from a laser diffraction system requires the sample's dispersion state to be controlled. The dispersant in which you measure a sample has a significant effect on its dispersion state. For example Figure 4 shows the particle size distributions of a Bentonite sample measured in both water and in isopropyl alcohol (IPA). In each case the sample has been fully dispersed. However, there is a 40 micron difference in the median particle size between the dispersants. Which result is representative of the mud performance will depend on the dispersion conditions within the mud system during use [3].

|

Most materials must be diluted to reach an appropriate concentration for laser diffraction measurements. During dilution of water-based muds it is important that the ionic strength of the dispersant is matched to that of the mud. This will aid dispersion and prevent dissolution of any of the salt based compounds. Important considerations for measurements of oil-based muds are the viscosity and surface tension of the dispersant.

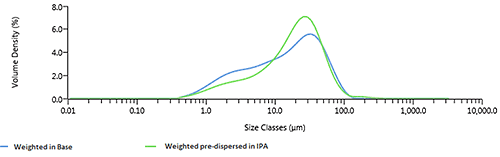

An example of the effect of the dispersant on particle size measurements is shown in Figure 5 where an oil-based mud, with 95% mud and 5% water, has been measured directly in base-oil and pre-dispersed in IPA (before being measured in base oil). The measurements in base oil show the water droplets and the result is slightly finer than the pre-dispersion in IPA where the water droplets have been removed. The correct measurement conditions will depend on the application and can often be determined by correlation with the physical properties of the mud and its behavior. For example, correlation with the rheological properties of the mud system may be important.

|

Particle size measurement of drilling muds is required to tailor the mud to the geological formation and drilling operation. Using laser diffraction provides rapid, reproducible particle size results for both water and oil based drilling muds. This allows simple routine testing of the mud to be carried out during planning as well as production.