The physical components and features of a Differential Scanning Calorimeter (DSC) instrument and the technical specifications are clearly important to consider when purchasing a new system. However, written specifications can be confusing, misleading and may actually have very little bearing on the actual performance of the instrument. Specifications, on paper, do not necessarily translate into advantages or disadvantages when it comes to making measurements on your samples. The best components and technical specifications in the world do not matter if the instrument is not assembled or optimized in a way that translate into real improvements in data quality and ease of use when you are working with your samples.

Here are some questions you should ask yourself as you begin evaluating differential scanning calorimeters.

All vendors have their own jargon and ways in which they like to present their specifications and instruments. However, all considerations about DSC instruments must start with an understanding of your application requirements and how specifications and features impact upon them.

A popular way to assess the sensitivity of an instrument is to compare the noise. This may seem reasonable but these values can be difficult to compare from one vendor to the next as each will define noise differently.

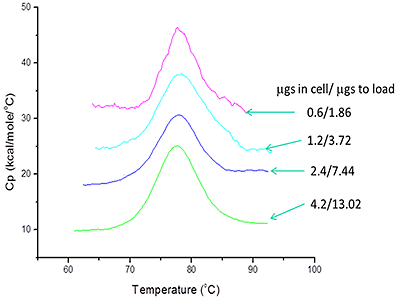

Good ways to check the sensitivity are to either run samples at low concentrations and perform repeat experiments or, if you have a test system that is not concentration dependent, run samples at a series of concentrations and compare the derived values (see figure 1)

In addition to assessing the calorimetric sensitivity of the instrument you should also consider the volume of material required by the user to fill the cell properly. There is a large variation in the volume requirements for the DSC instruments that are available on the market. So, when choosing a DSC you should consider the amount of sample (weight) as well as the sample concentration (see figure 1).

|

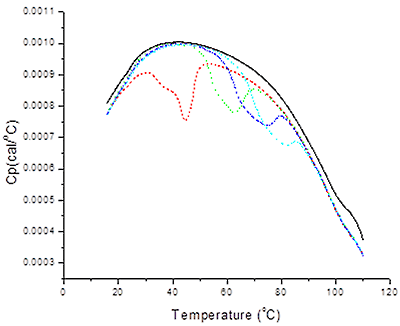

You should check the suitability of the instrument for your specific applications and buffer types. For instance, platinum has thermal properties that make it suitable for use in a DSC cell but it is commonly used as a catalyst making unsuitable for a range of applications. In our hands we have noticed issues with platinum with a number of commonly used buffer and therefore should be avoided when studying an array of biological systems (see figure 2) Need comments pointing to different plots explaining phenomena etc

|

Some DSC instruments can run samples at 240°C/hr. This fast scan rate allows for maximizing the number of measurements that can be run in a day. Check the scanning rate options on all the DSC instruments that you assess.

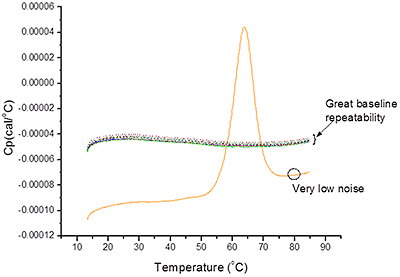

Baseline repeatability is an important factor to consider if you plan on using your calorimeter for detailed thermodynamic studies. You should check how well the profiles of the blank buffer scans agree through a series of experiments conducted under the same settings. Like many instruments DSC needs a few start-up runs to establish repeatable performance. Following these initial runs profiles of the buffer scans should be very similar with only minor shifts in the Y-axis position and shape. There are specifications for baseline repeatability but it would be useful to test this by making a few measurements of your own.

|

User friendliness is in the eye of the beholder, so check out the features that are most important to you. The best way to do this is to run the instrument and perform the data analysis yourself. By sending samples to vendor’s lab and receiving a report in the post at some time in the future will not help you to understand how to operate an instrument, run a sample or analyze data. Ask to use the software and run an experiment or two from start to finish. You’ll be glad you did because only then will you have a true understanding of how-user friendly and time saving the instrument and the software are for your requirements.

There are a wide range of macromolecules and macromolecular assemblies that can be studied using DSC. If the instrument will be used by a number of research groups and/or by a team with broad interest in macromolecular assembly, you should make sure that the instrument you purchase can accommodate the specific requirements for each of these applications. For instance, some assemblies such as lipid micelles have very narrow transitions that are complete over 2-3°C whereas protein denaturation profiles typically occur over the 20°C range. Some micro-calorimeters have user selectable response times which can be used to optimize the performance of the instrument for different applications. So, if broad applicability is important to you then you should look for this type of flexibility in your DSC.

It is important to assess the reputation of the manufacturer or vendor that you use. DSC instruments must be manufactured using high standards and engineered by solid, technology leading companies in order to yield publication quality or decision making results.

Look for a manufacturer that has a suitable history of being at the forefront of developing and optimizing these instruments. These companies will produce instruments with good machine to machine variability and be the first to develop innovative advances to the technology and its applications. Such companies have been through the learning curve and you will benefit greatly as a result. These companies are much more likely to have the expertise, experience and support resources to not only build great instruments but also to support them properly.

Once you purchase your instrument your experience is really just beginning so it is important to purchase a system from a company that offers acceptable service and post-sales support.

Look for a company that can provide telephone, in –person and email support, ongoing training opportunities, field base service and expert level support. Before you purchase an instrument ask about what support is offered and may be ask to try some of these before making your decision so that you can get a feel for the quality and depth of the support you can expect once you have your new instrument installed in your lab.

Absolutely not.

DSC instruments can vary greatly in their design, quality and performance.

Even though different instruments may have specifications that look similar on paper, instruments vary greatly in real-life performance, quality and longevity. As with many things in life, the cheapest option is often not the best long-term value and usually winds up costing you more in the long run. Instruments that are slow and have poor repeatability end up costing a lot in terms of the extra sample and the time needed to generate data.