Asphalt binder emulsions have proven to be an environmentally friendly, energy efficient, and cost-effective alternative to hot asphalt binder mixtures [1]. They are typically used for roadway resurfacing where they are employed as an adhesive for post-applied aggregate chip. They are typically composed of bitumen, water, and an emulsifying agent or surfactant and must give the required stability and application characteristics for optimum performance. For example, the structural layers must have adequate mechanical properties to make them less susceptible to early-life damage.

The main component of asphalt emulsions is asphalt cement which constitutes 50-75 percent of the emulsion content. Its properties are critically important since they influence emulsion behavior and performance on the road [1]. Water is the next component and can affect the properties of the emulsion if minerals or other materials are present. One of the most influential components is the emulsifier or surfactant, and more specifically its chemical structure. The emulsifier can determine whether the emulsion is cationic, anionic, or non-ionic. Furthermore, the chemical compatibility of the emulsifier with the asphalt cement greatly affects the emulsions’ stability. The physical properties of asphalt emulsions can also be modified using additives such as polymers or fillers. There are many reasons to modify asphalt emulsions, including; improved resistance to permanent deformation at high temperature; increased low temperature flexibility; improved fatigue resistance; increased tensile strength; and reduced temperature susceptibility.

Malvern Panalytical has several tools that can provide valuable metrics for production and characterization of asphalt emulsions. The two tools discussed in this application note are the Mastersizer and the Zetasizer., which can both be used to determine droplet/particle size, and in the case of the Zetasizer to measure the Zeta potential of emulsions also.

Asphalt binder emulsions have proven to be an environmentally friendly, energy efficient, and cost-effective alternative to hot asphalt binder mixtures [1]. They are typically used for roadway resurfacing where they are employed as an adhesive for post-applied aggregate chip. They are typically composed of bitumen, water, and an emulsifying agent or surfactant and must give the required stability and application characteristics for optimum performance. For example, the structural layers must have adequate mechanical properties to make them less susceptible to early-life damage.

The main component of asphalt emulsions is asphalt cement which constitutes 50-75 percent of the emulsion content. Its properties are critically important since they influence emulsion behavior and performance on the road [1]. Water is the next component and can affect the properties of the emulsion if minerals or other materials are present. One of the most influential components is the emulsifier or surfactant, and more specifically its chemical structure. The emulsifier can determine whether the emulsion is cationic, anionic, or non-ionic. Furthermore, the chemical compatibility of the emulsifier with the asphalt cement greatly affects the emulsions’ stability. The physical properties of asphalt emulsions can also be modified using additives such as polymers or fillers. There are many reasons to modify asphalt emulsions, including; improved resistance to permanent deformation at high temperature; increased low temperature flexibility; improved fatigue resistance; increased tensile strength; and reduced temperature susceptibility.

Malvern Panalytical has several tools that can provide valuable metrics for production and characterization of asphalt emulsions. Two tools highlighted here are the Mastersizer and the Zetasizer.

The Mastersizer 3000 uses the technique of laser diffraction to determine the particle size distribution by measuring the angular intensity of light scattered as a laser beam passes through a particle dispersion - large particles scatter light at small angles and small particles scatter light at large angles. The particle size distribution is obtained by analyzing the scattering pattern using a model such as the Mie theory of light. The Mastersizer can provide accurate particle size distributions for both wet and dry dispersions in the size range of nanometers to millimeters. Laser diffraction provides a droplet size distribution, showing the size population distribution of millions of droplets. This plot can show if the emulsion is becoming finer or coarser which has several effects on the coating process of the emulsions. Finer particles and narrower distributions set and cure faster, while width of the distribution can affect the flow-behavior and stability of the emulsion, so must be precisely controlled.

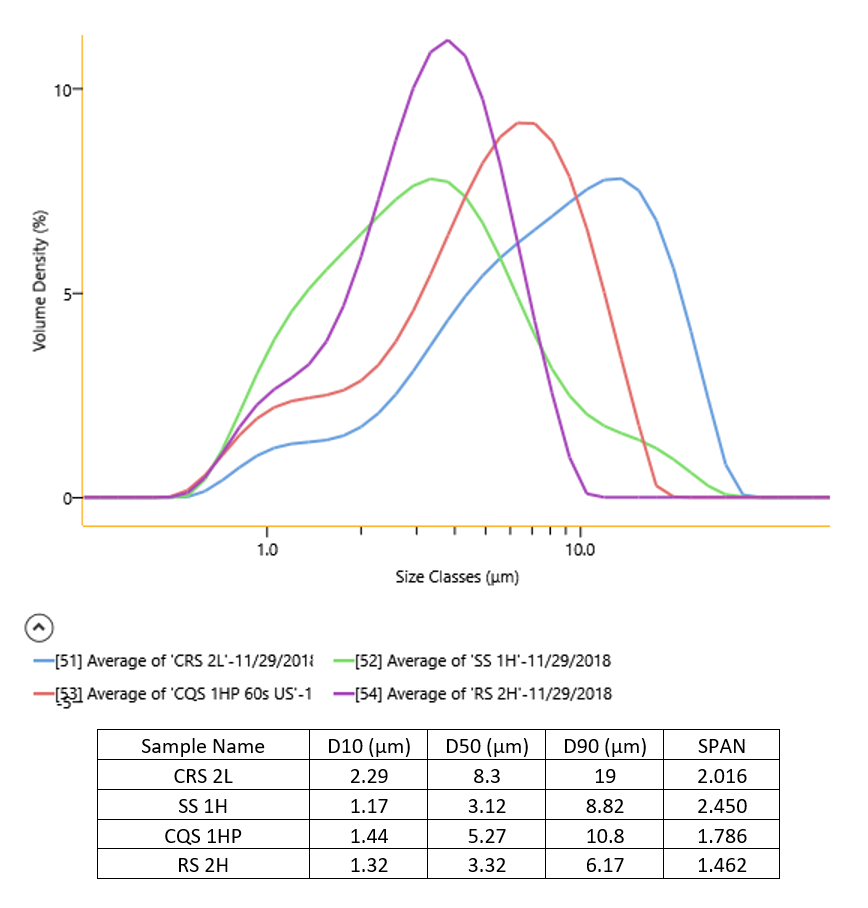

Figure 1: Volume-based Particle Size Distribution of 4 Asphalt Emulsion

Figure 1 shows the results of 4 different asphalt emulsion samples measured on the Mastersizer 3000. Per ISO 13320:2009, laser diffraction data is to report 3 size parameters: D10, D50 and D90. These D-values (D10, D50 & D90) are the intercept for 10%, 50% and 90% respectively of the cumulative volume. The other statistical number that is commonly used for laser diffraction is SPAN which is calculated by (D90-D10)/D50. SPAN will increase as particle size distribution width broadens. The Mastersizer 3000 was able to clearly differentiate 4 asphalt emulsion samples even though these samples have similar particle size range and median size.

The Zetasizer can be used to measure particle size through dynamic light scattering (DLS), and zeta potential through electrophoretic light scattering (ELS). DLS measures the diffusion of particles moving under Brownian motion and converts this to particle size and particle size distribution using the Stokes-Einstein relationship. Non-Invasive Back-Scatter (NIBS) technology is incorporated to give the highest sensitivity within the broadest range of sizes and concentrations. Furthermore, the Zetasizer Ultra now includes a new cuvette design called the Low Volume Capillary Sizing Cell. This new cell only requires only 3 microliters of sample and extends the size measurement range for dynamic light scattering to 10 µm without the need to density-match the dispersant. The cell enables repeatable analysis even at the ultra-low sample volumes, delivering high quality data whilst reducing cost.

The Zetasizer can measure particles from less than a nanometer to several microns in size, complementing the range offered by the Mastersizer mentioned above. With ELS or zeta potential analysis, an electric field is applied to a dispersion of particles which move with a velocity related to their surface charge. This velocity is measured using a patented laser interferometric technique called M3-PALS (Phase Analysis Light Scattering). This enables the calculation of electrophoretic mobility, and from this, the zeta potential and zeta potential distribution of a sample.

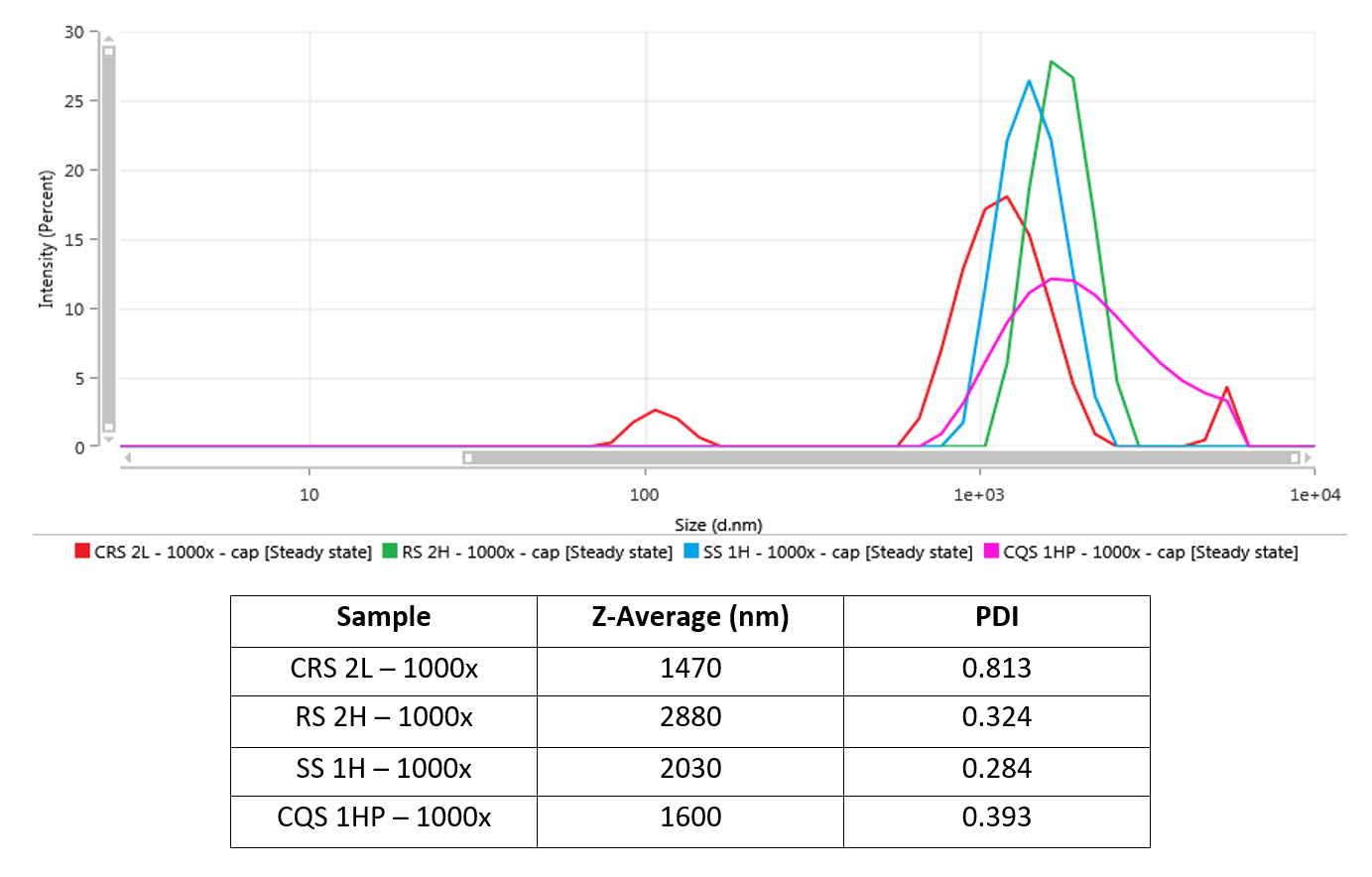

Figure 2: DLS showing particle size distributions of different asphalt emulsions with relatively broad distributions with high PDIs

As shown in Figure 2, the Zetasizer can be used to measure the average size and degree of polydispersity of asphalt emulsions using the Z-average and Polydispersity Index (PDI). The Z-Average size or Z-Average mean used in dynamic light scattering is a parameter also known as the cumulants mean. It is the primary and most stable parameter produced by the technique. The Z-Average mean is the best value to report when used in a quality control setting as it is defined in ISO13321 and more recently ISO2412, which defines this mean as the ‘harmonic intensity averaged particle diameter’. The Polydispersity Index is a number calculated from a simple 2-parameter fit to the correlation data (the cumulants analysis). The PDI is dimensionless and scaled such that values smaller than 0.05 are rarely seen other than with highly monodisperse standards. Values greater than 0.7 indicate that the sample has a very broad size distribution and is probably not suitable for DLS. The calculations for these parameters are defined in the ISO standard document 13321:1996 E and ISO 22412:2008. The detectable range for the Zetasizer is 0.3 nm to 10 micrometers.

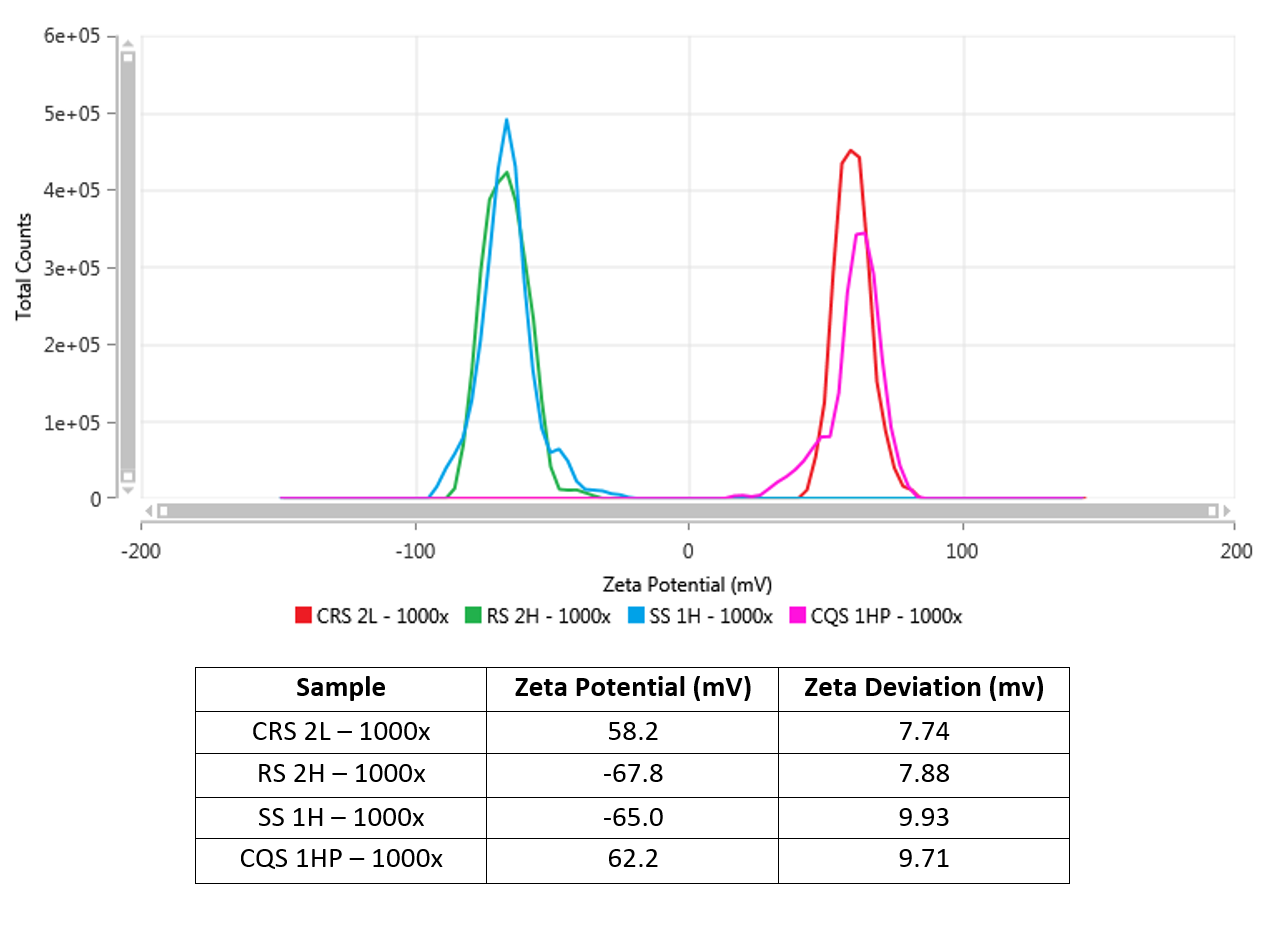

Figure 3: ELS showing zeta potential of different asphalt emulsions. Both CRS 2L and CQS 1HP had positive zeta potentials while RS 2H and SS 1H had negative values

Zeta potential is another common metric for stability and formulation applications. Emulsion droplets must be stabilized through a steric or charge repulsion mechanism. In the latter case zeta potential is a key metric, with high positive or negative Zeta potentials (usually > 30 mV) required to achieve a stable system. Zeta potential can be influenced by charge state, pH, additive concentration, and ionic concentration among other factors. Figure 3 shows the Zeta potential distributions for several formulations are exhibiting a higher absolute value for zeta potential. Chemists routinely use Zeta potential to characterize the colloidal stability of the overall emulsion and to evaluate the behavior of different emulsifiers and dispersion conditions.

The Mastersizer and the Zetasizer can be both used to characterize asphalt emulsions. They complement each other with the following highlights: