What is Semiconductor Metrology?

Precision and quality are keywords in the semiconductor industry, a field that finds usage in every environment of today’s world. Semiconductor metrology refers to steps and practices that are being implemented in the area for the measurement and characterization of the physical and electrical properties of semiconductor devices and materials. Accurate dimensions and metrology determined by measurement results have been the key factors thus far for production processes with low tolerances and high performances.

Malvern Panalytical offers a range of advanced x-ray metrology solutions, tools, and technologies developed with the goal of supporting various stages of semiconductor manufacturing with non-destructive measurements, from material characterization to wafer inspection.

Metrology in semiconductor manufacturing

As previously established, Metrology plays a vital role in the semiconductor industry, by providing essential material characterization, measurements, and analyses.

As this industry continues to evolve with galloping steps, providing structural and chemical properties becomes increasingly critical in several key areas:

- Optimize Processes

Metrology tools help enhance manufacturing processes such as process control, yield enhancement and innovation and development, by continuously monitoring and giving fast feedback, thus ensuring higher yield rates and the further expansion of this industry towards ever-decreasing feature sizes - Ensure Quality Control

The quality standards of the semiconductor devices are strict and essential, which is why metrology ensures early identification of flaws or deviations from desired properties, allowing early intervention in the processes and reducing the likelihood of defective devices. The non-destructiveness of X-ray metrology allows its integration into the processes without compromising the integrity of the sample.

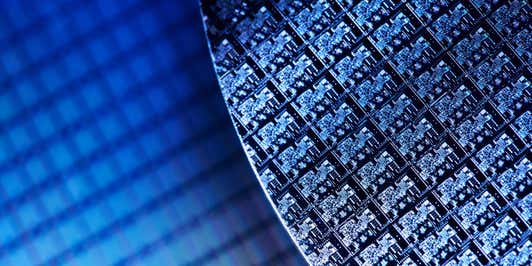

Why is wafer inspection important?

Wafer inspection refers to the process by which semiconductor wafers are structurally and chemically checked for defects, irregularities and inhomogeneities. This way any problems can be found long before the functional tests on the final device. Wafer inspection with x-ray metrology is often used to measure the following properties:

- Wafer mapping of film thickness and composition

- Wafer mapping of crystal quality using rocking curves

- High accuracy offcut measurements

Controlling these properties is critical to fabricating functional devices within their design specifications. Early detection enhances yield and saves time and resources in the long-term perspective.

Our semiconductor metrology instruments

Over the years, Malvern Panalytical has continued to provide its customers with high throughput and best-in-class solutions to support the ever-changing and ever-tightening process requirements in the semiconductor industry.

Malvern Panalytical is closely associated with the electronics industry with a wide range of solutions across the entire value chain:

- XRF (2830 ZT) delivers thickness and composition information for a wide range of thin films, with contamination and dopant levels and surface uniformity on wafers up to 300mm in size

- XRD (X'Pert3 MRD and X'Pert3 MRD XL) provides absolute, calibration-free, and accurate information on crystal growth, giving material composition, film thickness, grading profile, and phase and crystal quality

- Crystal orientation (Crystal Orientation Range) fast and accurate orientation for boule, ingot, puck and wafer applications

Featured products