Introduction

This white paper outlines the main benefits of using hard radiation for material analysis studies. X-ray powder diffractometers are generally equipped with X-ray sources using Cu anodes. For specific applications, however, switching to shorter wavelength, ‘harder’ radiation, like obtained from X-ray tubes with Mo or Ag anodes, gives significant improvements over Cu, or even allows experiments that are impossible with Cu radiation, like experiments where a large Q range needs to be probed.

Often, people make use of synchrotron radiation, but new developments on source, optics and detector technologies allow a variety of hard radiation experiments in the home lab. In this white paper we present six key advantages of hard radiation studies.

Larger penetration depth

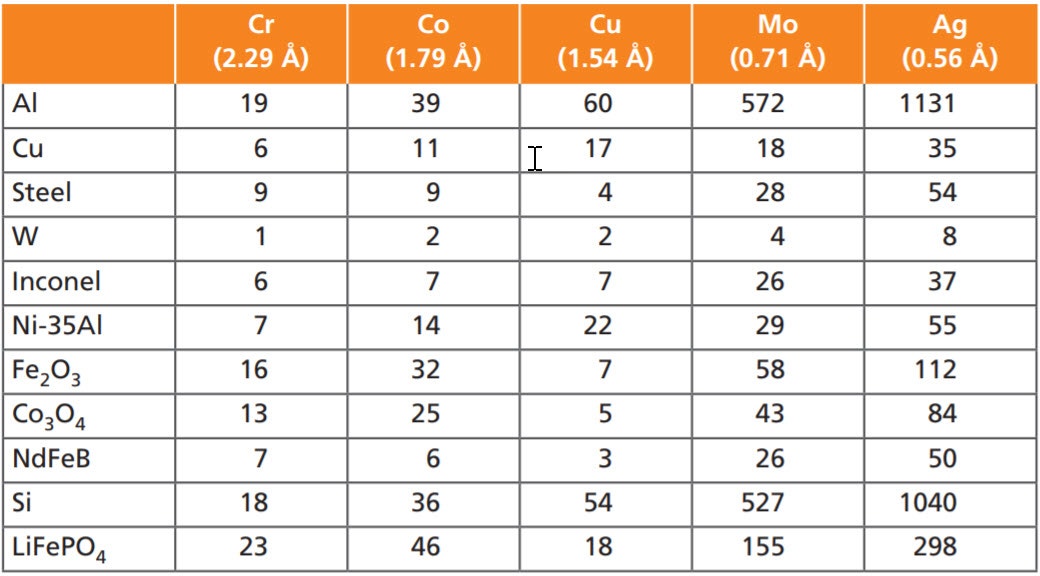

For inorganic materials, the penetration depth of Cu K-alpha is often only a few micrometers (see Table 1). In order to extract information from a larger sample volume, hard radiation is an advantage in transmission experiments. Thanks to the larger penetration depth, it is possible to observe crystallographic changes in working devices, such as Li-ion batteries, and perform highpressure experiments with diamond anvil cells. Hard radiation allows using transmission geometry for inorganic samples.

Table 1. Example of penetration depth in µm for different materials and different X-ray wavelengths

Login or create an account to read more.

Introduction

This white paper outlines the main benefits of using hard radiation for material analysis studies. X-ray powder diffractometers are generally equipped with X-ray sources using Cu anodes. For specific applications, however, switching to shorter wavelength, ‘harder’ radiation, like obtained from X-ray tubes with Mo or Ag anodes, gives significant improvements over Cu, or even allows experiments that are impossible with Cu radiation, like experiments where a large Q range needs to be probed.

Often, people make use of synchrotron radiation, but new developments on source, optics and detector technologies allow a variety of hard radiation experiments in the home lab. In this white paper we present six key advantages of hard radiation studies.

Larger penetration depth

For inorganic materials, the penetration depth of Cu K-alpha is often only a few micrometers (see Table 1). In order to extract information from a larger sample volume, hard radiation is an advantage in transmission experiments. Thanks to the larger penetration depth, it is possible to observe crystallographic changes in working devices, such as Li-ion batteries, and perform highpressure experiments with diamond anvil cells. Hard radiation allows using transmission geometry for inorganic samples.

| Cr (2.29 A) | Co (1.79 A) | Cu (1.54 A) | Mo (0.71 A) | Ag (0.56 A) | |

|---|---|---|---|---|---|

| Al | 19 | 39 | 60 | 572 | 1131 |

| Cu | 6 | 11 | 17 | 18 | 35 |

| Steel | 9 | 9 | 4 | 28 | 54 |

| W | 1 | 2 | 2 | 4 | 8 |

| Inconel | 6 | 7 | 7 | 26 | 37 |

| Ni35-Al | 7 | 14 | 22 | 29 | 55 |

| Fe2O3 | 16 | 32 | 7 | 58 | 112 |

| CO3O4 | 13 | 25 | 5 | 43 | 84 |

| NdFeB | 7 | 6 | 3 | 26 | 50 |

| Si | 18 | 36 | 54 | 527 | 1040 |

| LiFePO4 | 23 | 46 | 18 | 155 | 298 |

Better crystallographic information

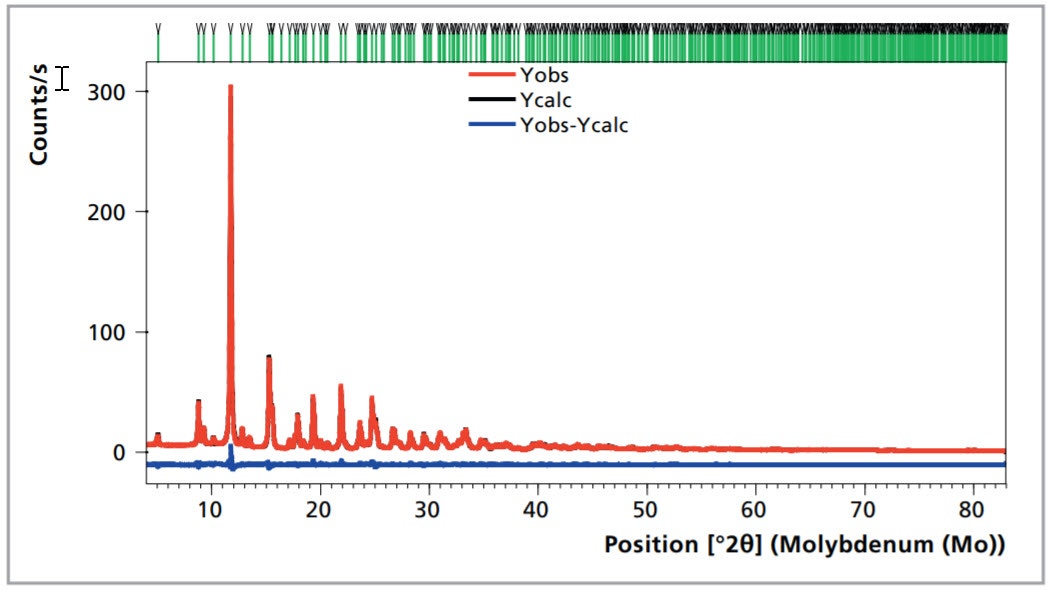

Crystallographers prefer to measure their samples in the Debye-Scherrer capillary geometry – preparing samples in glass capillaries is the best way to minimize preferred orientation effects of powdered samples. Working with Mo radiation in combination with optics focusing on the detector allows the usage of large-diameter capillaries without a loss in angular resolution or excessive absorption problems. Furthermore, it allows a better determination of the atomic thermal parameters like Biso.

Figure 1. Rietveld refinement of Fe(IO3)3 carried out with the HighScore suite [1]. Space group P63 with cell parameters a = b = 9.2361(1) Å, c = 5.23882(7) Å; Rwp = 2.4, GoF =3.4

Reliable information on the local structure of materials (PDF analysis)

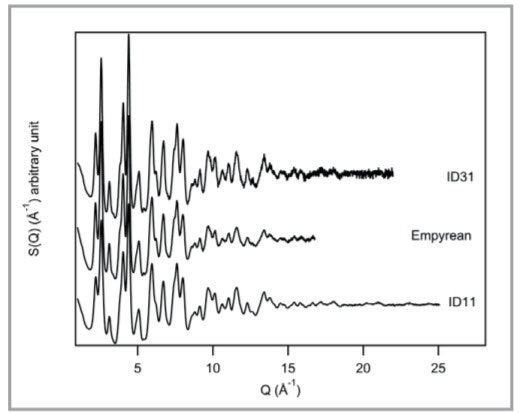

Pair distribution function (PDF) analysis, previously the domain of synchrotron sources, has become possible on laboratory multipurpose diffractometer, like the Empyrean, by a carefully optimized optical path with a low and featureless background. With Mo, a maximum Q range of 17 Å-1 can be reached and with Ag even 21 Å-1.

Figure 2. Structure function S(Q) comparison between two synchrotron beamlines and the Empyrean with GaliPIX3D, from [2].

Allowing X-ray imaging and computed tomography for a large class of materials

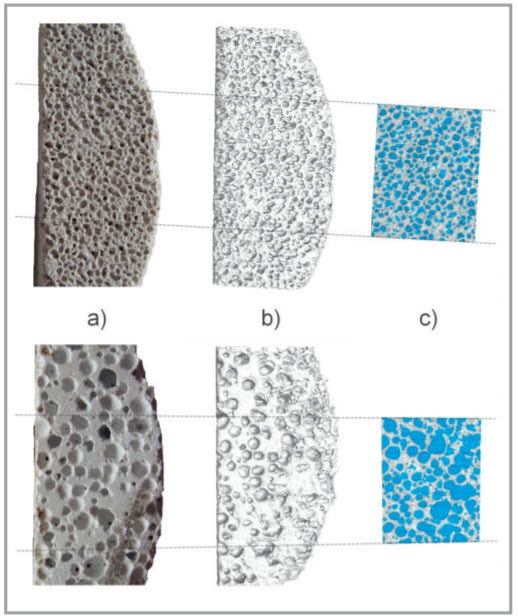

Hard radiation allows X-ray imaging and computed tomography for a larger class of materials. The more penetrating Mo or Ag radiation allows thicker and/or denser samples to be successfully evaluated.

Figure 3. Porous concrete. Top row with small pores, bottom row with large pores. a) picture of the concrete slab, b) 3D view using Isosurface render, c) cross section of the sample showing in more detail the pores (blue) and the concrete framework related to the selected area where the pores are determined in.

Hyper-speed data collection

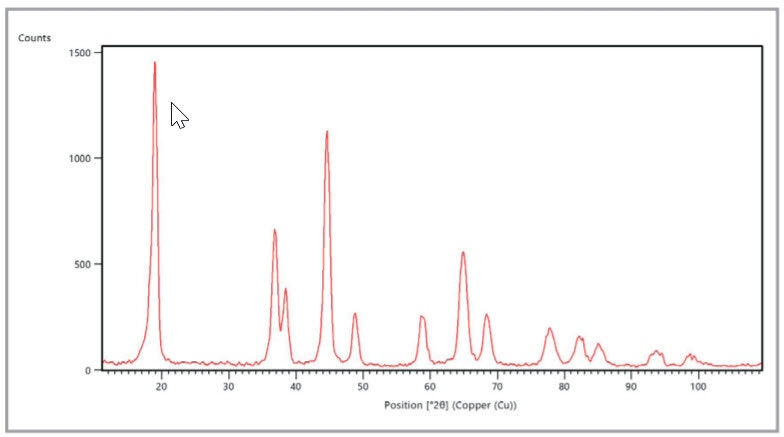

When using hard radiation instead of Cu radiation, the 2theta range required for collecting the same number of reflections decreases. A range of 100° 2theta with Cu radiation corresponds to ~30° 2theta with Ag radiation. A full-pattern one-second time resolution becomes possible.

Figure 4. Hyper-speed full pattern snapshot (33 deg with Ag radiation, equivalent to ~100 deg with Cu radiation) recorded in just 2 seconds.

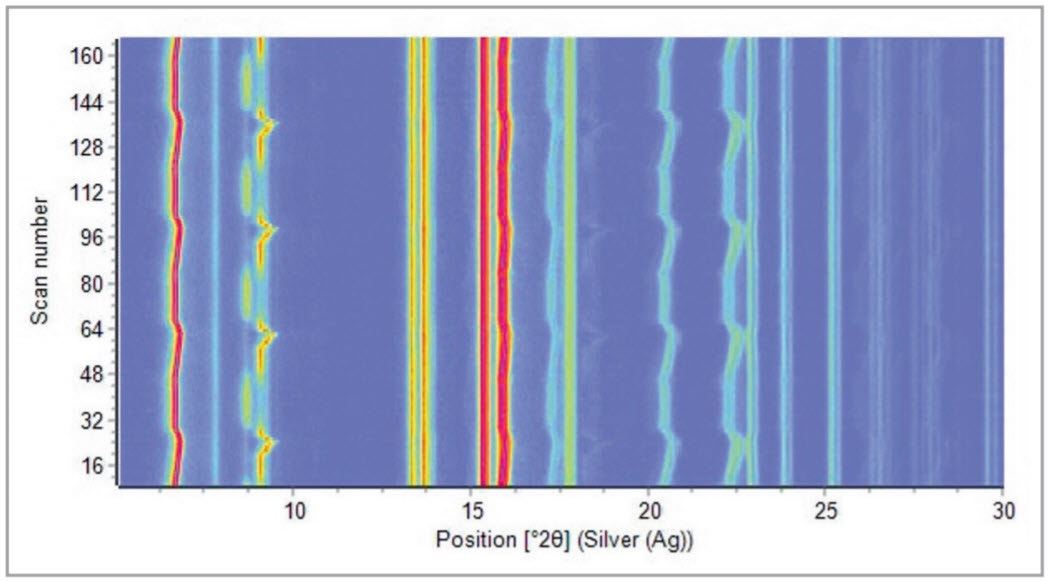

Better preparation for synchrotron beam time

Although lab systems inherently have a much lower X-ray flux, their main advantage is the direct availability. Samples can be tested prior to submissions for beam time so the chances for project approval increase.

Figure 5. Four complete charge-discharge cycles of a commercial prismatic battery cell, measured with Ag radiation (5 minutes per scan, 14 hours total measuring time).

Who should be interested in hard radiation studies?

Malvern Panalytical, your partner of choice for hard radiation applications

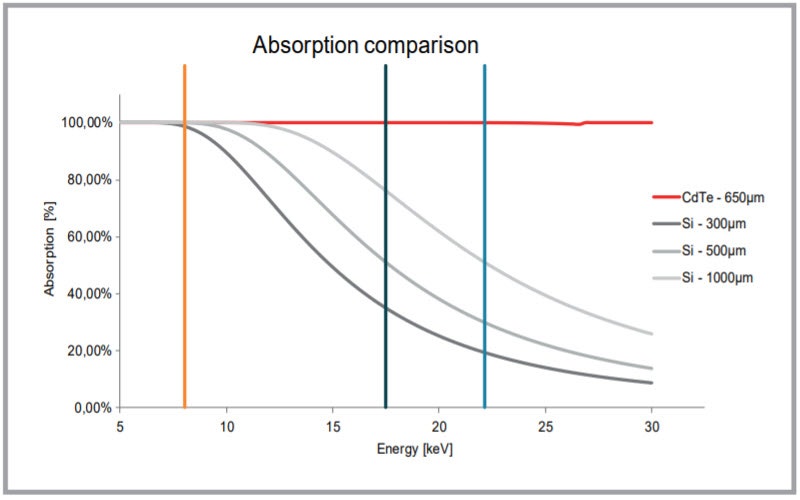

The Empyrean system has been designed for state-of-the-art data quality, including the much more demanding hard radiation applications. All following aspects of the system contribute to a superior data quality:

Figure 6. Detection efficiency as a function of photon energy for Si and CdTe with different thicknesses (h)

Bibliography

[1] T. Degen, M. Sadki, E. Bron, U. König, G. Nénert, Powder Diffraction 29 (S2), S13-S18 (2014).

[2] G. Confalonieri, M. Dapiaggi, M. Sommariva, M. Gateshki, A.N. Fitch, A. Bernasconi, Powder Diffraction 30(2), S65 (2015).

Acknowledgments

All trademarks ™ and copyrights © are the property of their respective owners. Copyright notice Copyright 2016, Malvern Panalytical, Almelo, the Netherlands. All rights reserved worldwide. No part of this document may be copied, distributed, transmitted, stored in a retrieval system or translated into any human or computer language, in any form or by any other means, electronic, mechanical, magnetic, manual or otherwise, or disclosed to third parties without the express written permission of Malvern Panalytical.

Disclaimer

Malvern Panalytical makes no warranties with respect to the contents of this document and specifically disclaims any implied warranties of merchantability or fitness for any particular purpose. Further, Malvern Panalytical reserves the right to revise or change this document without the obligation to notify any person or organization of such revision or change. The content of this document is checked on a regular basis and subsequent editions are issued when necessary.