The zeta potential of colloidal dispersions is routinely measured using laser Doppler electrophoresis. In this technique, a voltage is applied across a cell and the mobility of the particles undergoing electrophoresis is determined from the frequency shift in the scattered light detected..

The maximum conductivity specification for the Zetasizer Nano series is 200mS/cm. However, the higher the conductivity of the sample, the more difficult the measurements become. This is due to a number of factors which include Joule heating, electrode blackening (degradation), sample degradation (aggregation) and electrode polarization. The automatic settings of the instrument try to minimize these potential problems as much as possible. However, for some samples, manual set up of instrument parameters may be necessary to improve result repeatability.

The automatic settings used in the Zetasizer Nano software are discussed in further detail in the technical note "Automatic Settings for Zeta Potential Measurements in Version 5-00 Software" MRK835 available on the Malvern website.

This technical note discusses the ways in which zeta potential measurements for samples with high conductivity in the folded capillary cell can be manually set up with recommendations which may improve the results.

The default analysis model is Auto Mode which automatically selects the appropriate measurement protocol on the basis of the sample conductivity. The two models available are (1) General Purpose which calculates the mean zeta potential value and distribution of zeta potentials and (2) Monomodal which gives a mean zeta potential value only.

General Purpose uses a longer application of a steady field giving a higher degree of electrode polarization which can reduce cell and sample life. If the conductivity is greater than 5mS/cm (by default), Monomodal is automatically used. It is worth ensuring that the Monomodal analysis has been used for the sample being measured as this will minimize sample/electrode degradation and electrode polarization effects.

The quality factor is a signal to noise based parameter which determines the quality of the phase data obtained from the measurement. Further information on the quality factor can be found in the technical note "Assessing the Quality of a Zeta Potential Measurement on the Malvern Zetasizer Nano" MRK 836 available on the Malvern website.

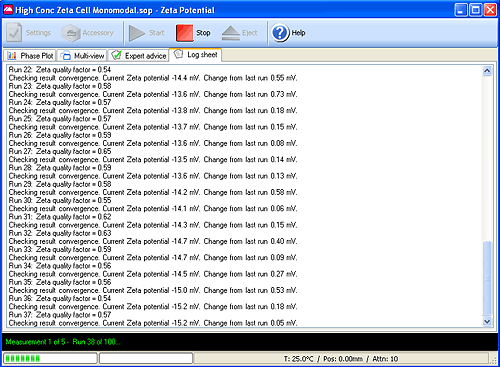

After a minimum number of sub runs (10 by default), the software checks the quality factor and this can be followed in the Log Sheet tab of the Live Measurement Window (figure 1). The result is accepted as reliable when the result quality reaches a value of 1. As a further check, the change in the mean zeta potential value, as successive sub runs are added, is also monitored and the measurement will only terminate when successive values fall within 0.5mV. If these criteria are not met, the runs will continue until the variation is less than 1% or the maximum number of runs is reached (by default, this is 100).

|

For some high conductivity samples, the quality factor initially shows a gradual increase over the first 30 or so sub runs, but may never reach the acceptable limit of 1. Continued sub run accumulation can then result in sample/electrode degradation causing the quality factor to decrease (see figure 1 for an example). If the value of the quality factor starts to gradually decrease in this manner, it is recommend to manually define the duration (i.e. number of sub runs) to stop the measurement before this point is reached. The number of sub runs to be used should be determined experimentally from the information shown in the Log Sheet.

For some samples, it is recommended to manually specify the number of sub runs per measurement. Limiting the number of sub runs per measurement should help to minimize electrode polarization/degradation and sample degradation. It should be noted that this approach may result in data where the quality factor does not reach a value of 1. However, there is a trade off between the quality of the data obtained and minimizing sample degradation. The most appropriate number of sub runs defined per measurement should be determined from a series of experiments on the sample.

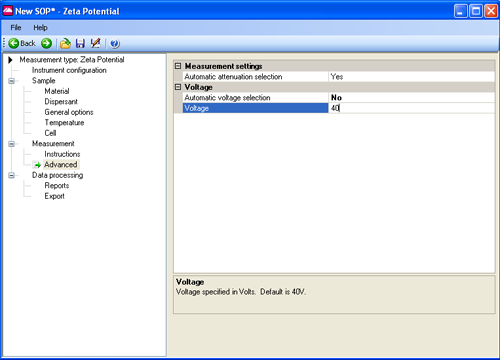

In Automatic mode, the voltage is automatically selected for the zeta potential measurement in the folded capillary cell based on the measured conductivity (table 1). The applied voltage is automatically reduced as the conductivity increases to limit the current and hence extend the life of the cell and sample. However it may be necessary to further manually reduce the voltage. Setting the selectiom to "No" will allow manual selection of the applied voltage (figure 2).

|

| Conductivity (mS/cm) | Voltage Selected (V) |

|---|---|

| < 5 | 150 |

| 5 to 30 | 50 |

| > 30 | 10 |

The voltage should be reduced gradually to determine an optimum value. This will become apparent from the reduction in the repeatability of the results obtained due to the reduction in the electrophoretic mobilities of the particles being measured.

An important point to make here is that a manual reduction in the applied voltage will reduce the quality of the data obtained from the measurement due to the reduction in the electrophoretic mobility of the particles. To try and compensate for this, the number of sub runs defined per measurement may need to be increased. In some cases, this may have to be in excess of 100 before good data quality is obtained. During method development, the optimum settings for the applied voltage and the number of sub runs used per measurement will need to be ascertained by experiment.

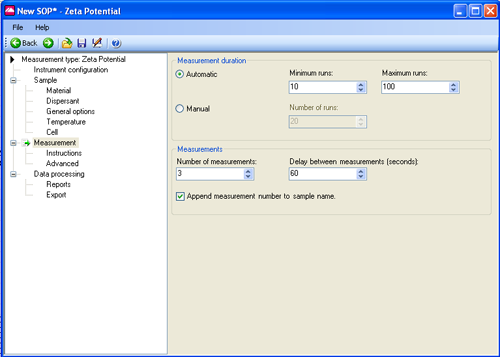

The repeatability of the zeta potential results obtained for a sample is important to determine. However, for some high conductivity samples, it may be necessary to reduce the number of repeat measurements performed on a sample. It is recommended to use a maximum number of 3 repeat measurements to try and minimize sample/electrode degradation and extend the life of the folded capillary cell. There will be a trade off between the repeatability of the results obtained and minimizing sample degradation.

For some samples, improved repeatability can be achieved by including a pause between repeat measurements. Typical pause durations of 30 or 60 seconds are recommended. This can be set in the Measurement dialogue as shown in figure 3.

|

The folded capillary cell is made from polycarbonate with gold plated electrodes. For some samples with high conductivities, a better option may be to use either the dip cell or the high concentration zeta potential cell. These optional accessories for the Zetasizer Nano instrument range have palladium electrodes which may be better suited to certain sample types.

This method, describes in document MRK1650 on the Malvern Instruments web site, separates the sample from the electrodes by injecting it as a 'plug' in the centre of a folded capillary cell. This has two advantages. It ensures that the sample is never in contact with the electrodes, and a much smaller volume of sample is required.

This is of particular use for measurements of macromolecules such as proteins, where aggregation on contact with the electrodes is likely, and the amount of sample for measurement may be limited.

The measurement of samples with high conductivities is far from easy due to a number of factors such as Joule heating, electrode blackening (degradation), sample degradation (aggregation) and electrode polarization. Even though the automatic settings used in the software try to optimize the measurement, there may be applications where further manual set up of the measurement may be beneficial.

Various recommendations are highlighted in this technical note and are summarized below: