The phase change from amorphous to crystalline state which occurs upon thermal annealing in the prototypical material Ge2Sb2Te5. Phase Change Materials (PCM) thin films is studied by concomitant, complementary and combined in-situ and X-ray diffraction (XRD) and X-ray reflectometry (XRR) techniques. Combined in-situ X-ray scattering techniques demonstrates the possibility to investigate with accuracy the structural, morphological and mechanical variations occurring in the films upon crystallization. The crystallization process is correlated to a volume shrinking (densification and thickness reduction) and to structural change with the building up of tensile strain. The combined XRD/XRR analysis gives new insights on the stress components built up in phase change material. Afterwards, concomitant grain growth, viscous flow, densification and thickness accommodation are observed which leads to a partial stress relaxation in the PCM films. This combined characterization techniques proposes a new approach in order to go further into the understanding of the involved phase change.

The concept of PCRAM (Phase Change Random Access Memory) attracts great interest and appears to be suited for the next generation of memories [1] PCRAM has a simple device structure and a short write/erase time. In phase change memory, Phase Change of a Material (PCM) from amorphous state to crystalline state is used for the set and the reset processes. The phase change is followed by a change in electrical resistivity of several orders of magnitude. This drastic electrical change is used to store bits of information. Today, germanium antimony telluride (Ge2Sb2Te5) PCM is considered as a reference compound because of its excellent properties with respect to crystallization speed, crystallization temperature and/or retention time. Despite of the extensive studies, phase change mechanisms, and specifically volume shrinking behavior during crystallization, are not fully understood. To access structure, strain or stress state and volume shrinking, combined in situ X-ray diffraction (XRD) and X-ray reflectivity (XRR) experiments were carried out on PCM thin films. The combination of XRD and XRR measurements is regularly used to study solid state reactions, the structural defects into high-k dielectrics materials or phase transitions into chalcogenides materials. Both in situ X-ray scattering characterization techniques, achieved successively (quasi-concomitantly) on the same goniometer, demonstrate the possibility to correlate during an annealing, the volume shrinking, the crystallization state, the structural state and the strain/stress state. Subsequently, the combination of the obtained results with both X-ray characterization techniques permit to propose a new approach further into the understand the crystallization behavior of the doped phase-change materials.

Samples are investigated by in situ by XRR and XRD using an Empyrean diffractometer.

Figure 2. X-ray optical pathway of the goniometer

| Source | Tube Ceramic Cu fine focus λ=1.5406 Å |

| Incident beam optics for XRR | Programmable divergence slit 1/32°, Soller slits 0.04 rad |

| Incident beam optics for XRD | Programmable divergence slit 1/4°, Soller slits 0.04 rad |

| Sample stage | Anton Paar HTK 1200, secondary vacuum (turbo-molecular pump, Pressure below 10-5 mbar) |

| Diffracted beam optics for XRR | Programmable anti scatter slit 1/32°, Soller slits 0.04 rad, PIXcel0D detector, receiving slit mode, 3 active pixels strips |

| Diffracted beam optics for XRD | Programmable anti scatter slit open, Soller slits 0.04 rad, PIXcel1D detector, scanning mode |

Prior to the measurement, a 5 minutes waiting time was set in order to ensure thermal equilibrium of the sample. High quality data require a proper alignment of the sample at each temperature. This was done afterwards, sample alignment operations are performed and takes only 5 minutes including a careful check of sample alignment. This step is critical and essential to get enough accuracy for data analysis. After sample alignment, a measurement cycle is defined as succession of an X-ray reflectivity (XRR) measurement and an X-ray Diffraction (XRD) measurement for each isothermal annealing step.

One full measurement cycle required around one hour: half an hour for XRR and half an hour for XRD measurements. The XRR measurement (

θ

-2

θ

scan at low angles) is performed in a pseudo parallel beam geometry within the 2

θ

range [0.2°-3°] (step size 0.0025°). Secondly, the XRD measurement (

θ

-2

θ

scan at high angles) is done in Bragg-Brentano geometry within the 2

θ

range [20°-60°] (step size 0.025°). The experimental set-up developed here exhibits the advantage to give the possibility to switch from XRR configuration to XRD configuration automatically without any user intervention including sample alignment. In order to slow down the kinetic of crystallization process, successive cycles of measurements were performed under isothermal annealing (at constant temperature steps) and at temperatures slightly below the onset of crystallization of the GST films. Then, the X-ray measurements time is synchronized and in accordance with the phase transformation and crystallization kinetic process. Note that an isothermal annealing only requires a unique set of alignment operations just after a short temperature stabilization time prior to starting the measurements. Then, the single alignment set gives better accuracy of measurements and extracted quantitative results. In addition, isothermal annealing is also well suited because no thermal dilatation effects of the environmental chamber nor of the sample holder are expected limiting any modification of the alignment during measurements. Only one set of alignments is necessary. Thus, very small relative density variations and d-spacing changes can be accurately observed by minimizing the alignment source errors. Additionally, under isothermal annealing, a better accuracy is achieved in d-spacing and in strain quantification, since there is no changes due to thermal expansion of the phase-change material during measurements.

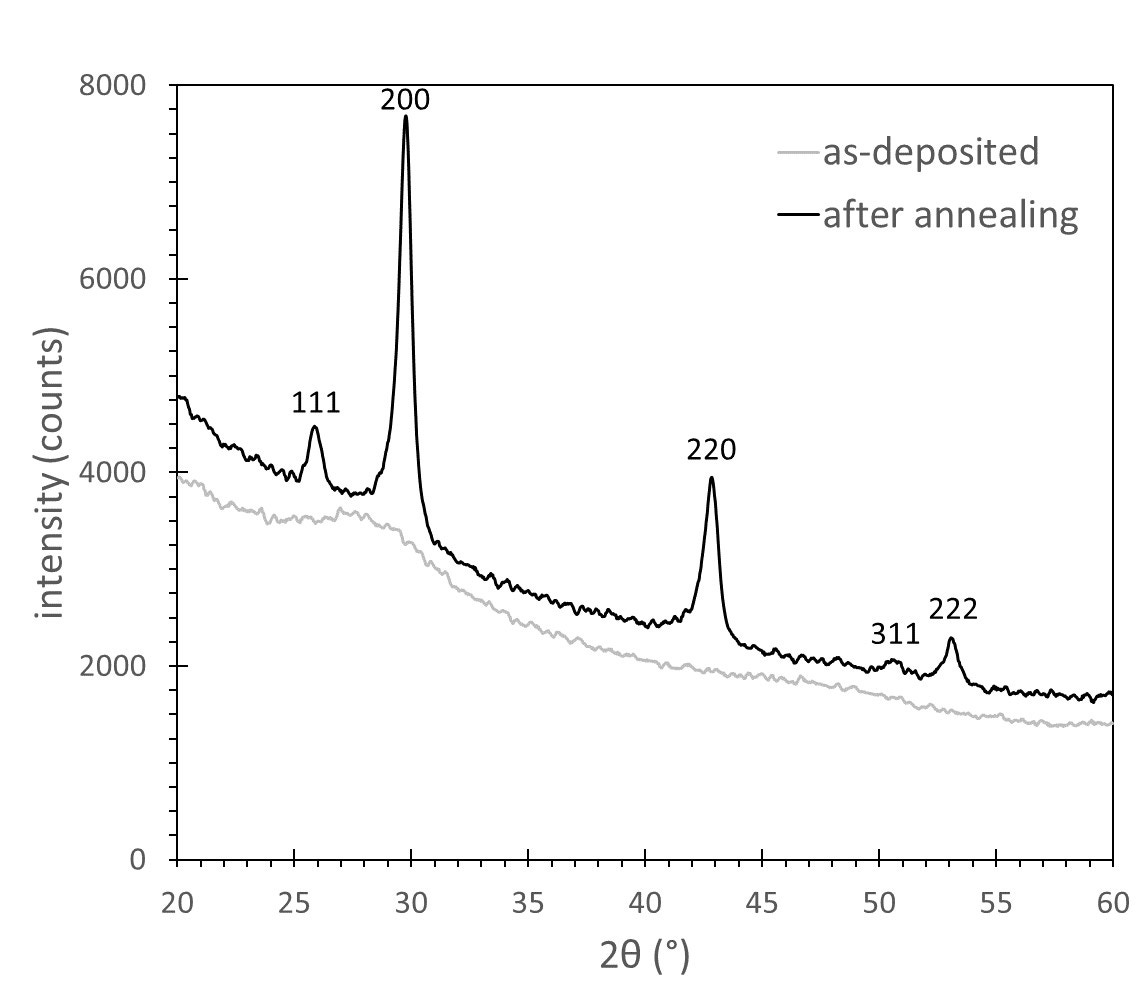

Figure 2 shows the diffraction patterns recorded at the end of the isothermal annealing. All the main reflections of the cubic FCC of the SGT phase are present without any evidence for impurity or other polymorph. The relative intensities between Bragg peaks are in accordance with the intensity ratio reported on the crystallographic datasheets (ICDD card, file n° 01-078-3710, 2006). This indicates that all the three samples are not textured. The diffraction pattern of the as-deposited sample is typical of an amorphous state with a broad hump at low angles.

Figure 3 shows the reflectivity patterns recorded on the as deposited sample and at the end of the isothermal annealing for the three samples.

Two Kiessig fringes (figure 8) components are observable for all samples: a long period component corresponding to the SiNx capping layer and short period component corresponding to the PCM film.

Figure 2 . Typical XRD patterns obtained on GST, films isothermally annealed at constant temperatures of 100°C. The curves shown here have been acquired before annealing and at last cycle of the isothermal annealing process. the cubic FCC K a reflections and K b artefacts are observable

The comparison of the

XRR curves reveals some significant density changes after isothermal annealing. A clear shift in the total reflection critical angle (

w

c

)

is observed between the initial and final state. It is evidenced as shown by the zoom in 2

θ

range [0.5°-0.8°].

The Kiessig thickness fringes also exhibit a period change between the initial and the final state after isothermal annealing. Zooms in 2

θ

range [1.5°-2.1°] as shown reveals a fringe’s period reduction which is the result of a thickness reduction.

Figure 3 . Typical XRR patterns obtained on GST, films isothermally annealed at constant temperatures of 100°C. The curves shown here have been acquired before annealing and at last cycle of the isothermal annealing process. The thickness fringes and the critical angle are observable.

Figure 4 and figure 5 show the gradual evolution of the GST film during the isothermal annealing at 100°C. The structural state evolution is extracted from the XRD results as shown in figure 4. The d-spacing, strain, and domain size DCD evolution are then followed in situ under annealing. The morphological state and the volume shrinking is described by the XRR results (figure 5). The density, thickness and surface mass ratio (not shown here) are then followed in situ upon annealing.

Figure 4. ⊥ (200) d-spacing (left) and diffracting coherent domain size (DCD, right)) extracted from XRD curve as a function of time during isothermal annealing (one measurement cycle corresponds to one hour). The isothermal temperature was fixed at 100°C

Figure 5. (a) Density (left) and thickness (right) extracted from XRR curve as a function of cycle number during isothermal annealing (one measurement cycle corresponds to one hour). The isothermal temperature was f ixed at 100°C

By cross correlation of the both set of results, the behavior of the PCM materials under crystallization process can thus be understood. Some of the main results are the followings: upon annealing the crystallization induces a considerable tensile strain build up in the PCM film. Afterwards, a partial strain relaxation occurs and is related to grain growth and viscous flow. Concomitantly, volume shrinking is observed through densification and thickness reduction. The in situ combination of XRR and XRD techniques is a powerful approach to provides a better understanding of the mechanism involved during the amorphous to crystalline phase transition. These understandings open new pathways to engineer volume shrinking into PCM and then to help the design and improve the reliability of high performance PCRAM memory devices. For more details see detailed article [2].

The phase change from amorphous to crystalline state which occurs upon thermal annealing in the prototypical material Ge2Sb2Te5. Phase Change Materials (PCM) thin films is studied by concomitant, complementary and combined in situ and X-ray diffraction (XRD) and X-ray reflectivity (XRR) techniques. Combined in situ X-ray scattering techniques demonstrates the possibility to investigate with accuracy the structural, morphological and mechanical variations occurring in the films upon crystallization. The crystallization process is correlated to a volume shrinking (densification and thickness reduction) and to structural change with the building up of tensile strain. The combined XRD/XRR analysis gives new insights on the stress components built up in phase change material. Afterwards, concomitant grain growth, viscous flow, densification and thickness accommodation are observed which leads to a partial stress relaxation in the PCM films. This combined characterization techniques proposes a new approach in order to go further into the understanding of the involved phase change.

[1] Noe et al., Semicond.

Sci. Technol.

33 (2018) 013002

[2] Fillot et al., J. of AppL. Cryst. 51 (2018) 1691