Fire suppression systems operate by removing heat and displacing oxygen from a fire so that combustion cannot be maintained. Different hazards require different liquids, powders or gasses to suppress the reaction. Water is the most commonly used fire suppressant as it is both inexpensive and does not raise environmental concerns.

Where water is used it is generally in the form of a hose or sprinkler system which produces large droplets and uses high volumes of water. These large volumes of water can cause equipment damage and result in long clean up times. There are therefore some applications in which traditional sprinkler systems cannot be used. For example, the volume of water required for a traditional sprinkler system makes it impractical for use in ships. Sprinklers are also not commonly used in machine spaces due to the level of damage caused by excess water and the resulting downtime. In these situations, other suppressant systems have been considered. For open spaces, powder or carbon dioxide based systems may be appropriate. For machine spaces, inert gases such as Halon can be used, although the use of such compounds in now tightly controlled as they are ozone depleting.

One way of improving the performance of suppression systems using water is to delivery the water as concentrated mist of fine droplets. To be classified as a mist rather than a sprinkler, the droplet size distribution delivered by the fire suppression system must have a Dv99 (size below which 99% of the volume of liquid is present) of less than 1000µm [1]. Using mist systems can significantly reduce the value of water required to control a fire, generally to less than one tenth of that required for a standard sprinkler system. Water mist therefore provide one means of managing environmental risks whilst also avoiding the damage caused by the large volumes of water used in conventional sprinkler systems (table 1). Common applications of water mist systems are therefore in gas turbine installations, machinery spaces, commercial cooking areas and ships.

Table 1: Comparison of sprinkler and mist systems

| Water mist | Sprinkler |

|---|---|

| Fine/controlled spray | Coarse/crude spray |

| Short spray duration | Long spray duration |

| Little water | Excessive water |

Water mists are produced when pressurized water is atomized through a nozzle. When the mist interacts with a fire the droplets evaporate removing the heat of vaporization from the fire. This lowers the temperature, whilst the resulting water vapor displaces oxygen so that combustion cannot be maintained. The droplet size distribution is therefore critical in determining the effectiveness of the mist for fire suppression. A spray containing finer droplets will have a greater surface area, leading to better heat transfer, more rapid vaporization and consequently faster fire suppression.

Although mists work well for small fires due to the suppression mechanisms described above, they can sometimes fail to bring large files under control. As suppression of the fire starts to occur, the energy available for vaporization decreases, reducing the effectiveness of the mist in removing energy from the fire. This can also result in insufficient oxygen displacement and prevent complete suppression. To improve suppression and prevent re-ignition, water mists are being developed with added surfactants, which cause foaming. Foams are good as suppressants, especially for fuel fires, as they spread over the surface of the fuel preventing evaporation. Hence by adding foaming surfactant the advantages of foam suppressants can be combined with those of a water mist system.

|

Surfactant enhanced fire suppression systems are complex products where the surfactant and water mix must be a vaporizing spray on the exit of the nozzle but must create spreading foam when in contact with the fuel surface. The particle size of the spray must therefore be controlled to ensure that fire suppression is achieved.

It is clear that characterizing the droplet size produced by fire suppression mist systems is an important part of understanding atomization dynamics and suppression efficiency. However, measuring these mists can be challenging as the nozzles produce wide spray plumes with high concentrations and high exit velocities.

One technique which can provide a means of complete characterization of mists is laser diffraction, using the Malvern Spraytec. Particle size information is obtained in laser diffraction by measuring the intensity of scattered laser light as a function of angle, where large particles scatter light at low angles and small particles scatter light at high angles. An appropriate scattering model can then be used to calculate the particle size distribution from this intensity angle data.

The design of the Spraytec allows for the technique of laser diffraction to be applied to a wide range of spray applications. The features which are particularly suited to the measurement of fire suppression systems include:

In this case the system has been used to look at how the addition of surfactant to a suppression mist system affects the mist particle size.

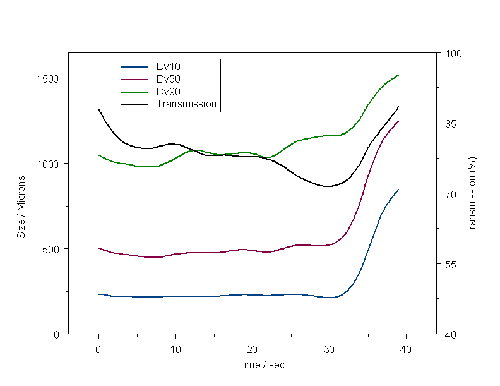

The output of the first suppression nozzle was initially characterized using water for which the droplet size was measured over the 40s taken to empty the reservoir of water. The measurement was carried out at a distance of 0.5m from the nozzle and using a water pressure of 3bar. The particle size history for this measurement is shown in Figure 2 where the Dv10, Dv50, Dv90 and transmission (related to concentration) are plotted as a function of time. This shows that the droplets size is relatively stable during the emptying of the reservoir. However, after 30s the droplet size increases, due to an unstable flow of liquid through the nozzle.

|

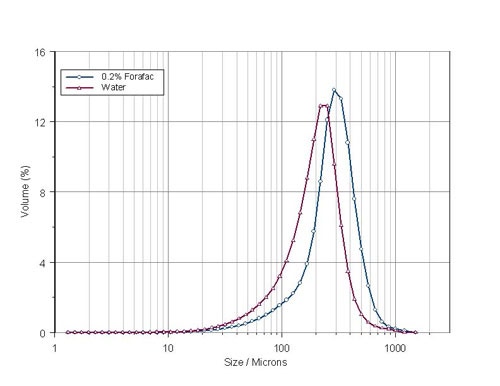

The nozzle was then tested with water containing ForafacTM (a surfactant containing fluorinated compounds) at concentrations of 0.05% and 0.2%. In this case a nozzle pressure of 12 bar was used, in order to ensure complete atomization. The median (Dv50) and surface area mean (D[3,2]) diameters obtained are shown in Table 2, whist the size distributions for the water mist and the 0.2% Forafac are shown in Figure 3. It can be seen that the droplet size increases as the concentration of surfactant is increased. Initially, this was not expected, as surfactants reduce the surface tension of the water, and would therefore be expected to facilitate the formation of finer droplets. However, the rate of diffusion of the surfactant molecules to the surface is slow compared to the speed of surface formation during atomization; therefore there is not sufficient time to form an equilibrium, low surface tension. This explains why no reduction in droplet size is observed when surfactant is added. The increase observed could be due to agglomeration or shear induced foaming of large droplets as they move away from the nozzle.

|

| Pure Water | 0.05% ForafacTM | 0.2% ForafacTM | |

|---|---|---|---|

| D[3,2] / μm | 133 | 167 | 187 |

| Dv50 / μm | 217 | 265 | 306 |

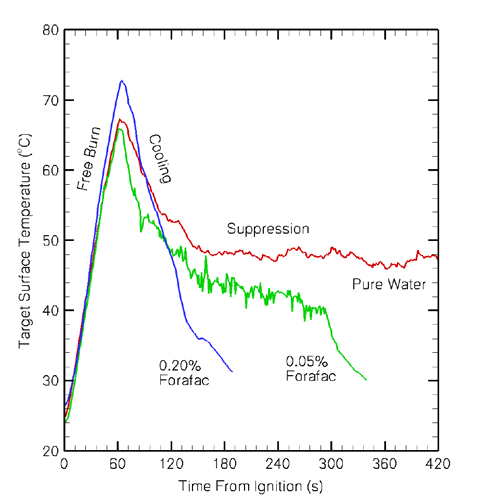

Finally, Figure 4 shows the data recorded during suppression experiments carried out with the water and surfactant enhanced mists. The experiment involves monitoring the surface temperature of a target within the compartment during free burn, cooling and suppression. The sharp increase in temperature represents free burning which occurs before the water mist had been released. The water mist is then released into the chamber and the temperature decreases sharply during the cooling phase. For the water mist the temperature profile shows that the compartment is quickly cooled and the flames are suppressed but the fire is not completely extinguished. However, the surfactant enhanced mists achieve much better suppression of the fire. Images from these tests show that with the 0.2% Forfac solution that after 20s islands of foam appear on the fuel surface and after 1 minute these islands have formed a complete layer. This limits oxygen accessibility to the fuel surface and reduces the size of the fire. Over time the 0.05% mist protected the fuel for 9 minutes where as the 0.2% mist protected the fuel for over 10 minutes.

|

As fire suppression systems, water mists provide significant advantages to traditional sprinkler systems. Water mists use a much lower volume of water which causes less damage to equipment and reduces clean up times. Foam is often used in fuel fires as it spreads to provide efficient coverage of the fuel, preventing re-ignition. Therefore surfactants are being added to water mists to improve the efficiency of these fire suppression systems. The droplet size distribution is a key factor in these systems, as the efficiency of cooling will depend on the droplet size. The Spraytec allows for complete characterisation these mist systems, under challenging conditions, underpinning studies critical to the development of optimised solutions for use in challenging fire suppression applications.

Suppression experiments show that although the pure water mist achieved rapid cooling the fire was not completely extinguished. However, the surfactant enhanced water mist show complete extinction of the fire with faster suppression at higher surfactant concentrations. Therefore the addition of surfactants to a water mist system aids in coverage of the surface of the fire and preventing re-ignition.

[1] NFPA 750: Standard on Water Mist Fire Protection Systems.

[2] Extending the working range of laser diffraction spray measurements, Application Note.

Malvern Instruments is very grateful to André Marshall and his research group at the Department of Fire Protection Engineering at University of Maryland for providing the data presented in this application note. For more details, please visit http://www.fpe.umd.edu/faculty-profiles/marshall.html.