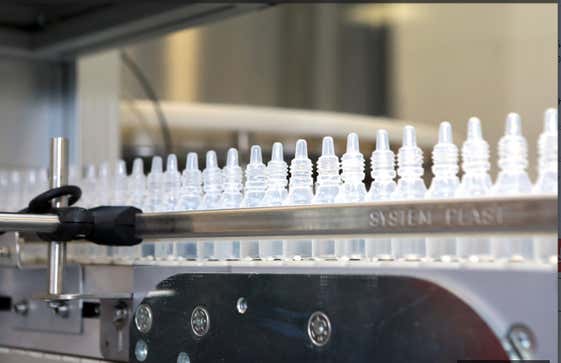

Orally inhaled and nasal drug product (OINDP) formulation

Physicochemical analysis of nasal sprays, nebulizers, dry powder inhalers and metered dose inhalers

Physicochemical analysis of nasal sprays, nebulizers, dry powder inhalers and metered dose inhalers

Already used extensively for local activity, orally inhaled and nasal drug products (OINDPs) also show great promise for the effective systemic delivery of a variety of therapeutics. Patient acceptability, rapid absorption, gastro-intestinal tract avoidance, and the opportunity for product differentiation are just some of the driving factors.

When developing either inhalers or sprays, the development of formulation and device go hand-in-hand. Changes made for one will affect the other, and vice versa. As an example, the design and geometry of a spray nozzle affects the stress on the suspension and thereby the spray droplet distribution. Likewise, a change of excipient may affect the formulation viscosity and how efficiently it can be pumped through the spray nozzle – this is critical, as the droplet size distribution influences where the drug is deposited in the repsiratory tract and therefore also impacts its bioavailability and speed of action.

Malvern Panalytical’s physicochemical analysis solutions help you understand the impact of your formulation and process decisions on the final drug product, guiding you to success.

When choosing your excipients, there are a number of considerations which may affect your formulation or even your final drug product. Excipients such as polymers are often used to modulate the viscosity of a suspension or solution. They can therefore often influence the ease of pumping or processing the suspension, and in nasal sprays or nebulizers can directly impact the spray droplet size distribution. The size distribution of drug carrier particles, such as lactose in dry powder inhalers, is critical for delivery of the drug to the lungs, and sometimes the shape of excipients and API particles can affect how they interact and flow during processing.

Malvern Panalytical have several tools that are commonly used for the analysis of ingredients or raw materials from different suppliers and can also be applied to determine whether different batches are the same or show differences.

Accelerated degradation studies of API and excipients

X-ray powder diffraction provides a unique insight into changes in drug crystal form, crystallite size and morphology, as well as changes to the amorphous:crystalline ratios of API in the formulation during accelerated stress studies to assess or optimize formulation stability.

Process development and process monitoring

Our physicochemical characterization tools are used to assess the stability of both APIs and excipients in a formulation, across processing conditions, to ensure that process parameters are controlled and optimized such that the final drug product meets the required Critical Quality Attributes (CQAs).

In any process, changes may be needed. Within the pharmaceutical industry, examples might include a change in the supplier of an excipient or API, a change of a piece of machinery, a move of a product between manufacturing sites, or a minor change in formulation composition. All of these changes must be controlled so that they don’t affect the final drug product.

Malvern Panalytical’s physicochemical solutions are all regularly used to help with comparability assessment to check for changes in a product when there has been a change in the process used to create it. In addition, our technologies are also used to show in vitro bioequivalence between reference and test products when generics are being developed. This testing can prove that the generic product and device combination delivers the same drug in the same manner as the innovator product, which can dramatically reduce the amount of clinical testing required and accelerate a generic pharmaceutical product’s route to market.