All NanoSight measurements are controlled by Standard Operating Procedures (SOPs) or scripts. A number of frequently used SOPs are provided with the instrument software.

The script control feature in NTA 3.2 allows the user to program a list of hardware or software commands for the software to follow. This can be useful in creating Standard Operating Procedures, or for time-based studies the commands can be entered and the instrument left to run automatically. Scripts can be run at the time of writing or created and saved for later use.

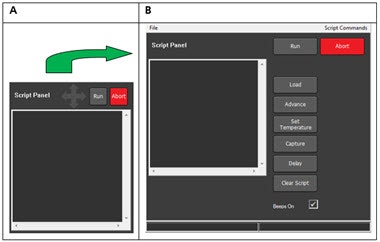

The Script Panel can be found on the left hand side of the screen, on opening the NTA 3.2 software. Place the mouse icon over the ‘Script Panel’ text and drag the panel out into the main NTA window area. The panel will expand as shown in Figure 1:

Figure 1. A; Script Panel in NTA3.2 opening screen; B: Expanded Script Panel

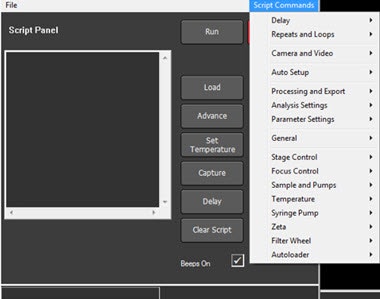

Shortcuts to commonly used commands are shown to the right of the commands window within the Script Panel. Clicking on the ‘Script Commands’ menu at the top right of the panel will bring up a directory structure, listing all the commands available for your specific NanoSight system configuration, as shown in Figure 2. Click on a command to add it to the commands window within the Script Panel. Some commands will then also require additional parameters or values to be added.

Figure 2. Script Commands directory structure in NTA3.2 software

Commands can also be entered by typing directly in the window, or by copying and pasting from elsewhere in the commands window or from other text editors.

A script run can be started or aborted with the ‘Run’ and ‘Abort’ buttons, respectively. To save a script or load a previously saved script back into the command window, click on the File menu at the top left of the Script Panel. The Script Panel can be re-docked back into the main NTA software screen by double clicking on any blank area of the panel.

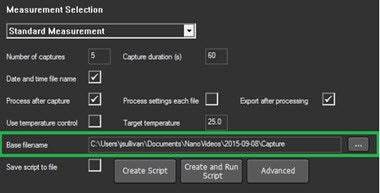

All data captured using the Script Control will be saved according to the folder and filename currently selected in the SOP tab, as shown in Figure 3.

Figure 3. SOP tab showing the Base Filename location in NTA3.2 software

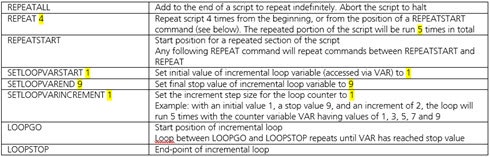

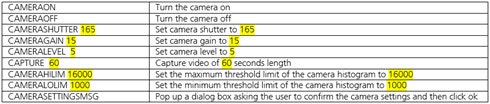

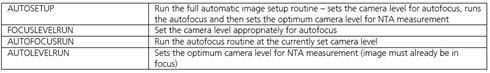

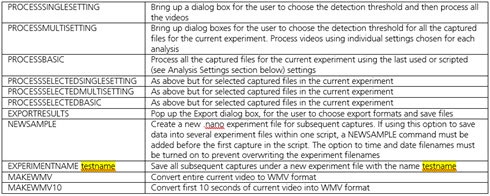

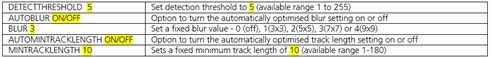

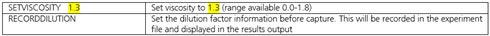

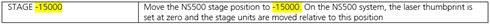

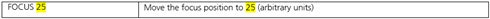

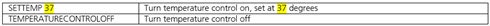

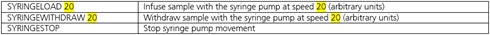

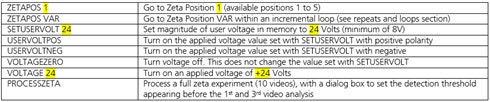

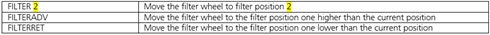

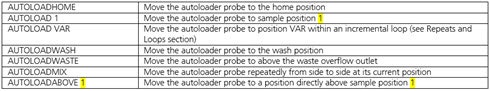

The usage and syntax for all NTA 3.2 commands are listed below. The full list given here will not be available on all NanoSight instruments; the commands that can be used will depend on the specific system configuration. Any additional parameters required should be entered with a space following the command. Required parameters are indicated by text highlighted in yellow below, with an example value shown.

Requirement:

Scripted process to hold the loaded sample temperature at 37oC, and run an NTA measurement of 60 seconds' capture duration every 5 minutes for half an hour, starting immediately after the sample temperature is initially set. All videos should be captured at camera level 10 and analyzed at detection threshold 5.

MESSAGE Ensure sample is loaded into the chamber and instrument is set at the measurement position ready for analysis

SETTEMP 37

CAMERALEVEL 10

CAPTURE 60

REPEATSTART

DELAY 240

CAMERALEVEL 10

CAPTURE 60

REPEAT 5

TEMPERATURECONTROLOFF

DETECTTHRESHOLD 5

PROCESSBASIC

EXPORTRESULTS