Viscosity flow curve. Part 2

How to best measure a viscosity flow curve?

Choosing the right measuring geometry and preventing measurement artifacts

There are several ways to obtain viscosities at different shear rates using a rotational rheometer. For instance, we could gently ramp through the different speeds starting at the lowest and ending at the highest (good for a quick measurement where time is of the essence). Alternatively, we could step through the required shear rates as discussed later, while waiting for a steady state viscosity at each step. This is known as generating an equilibrium flow curve and is generally considered the better way to make the measurement, as the results are more reproducible across different instruments and geometries (measuring systems).

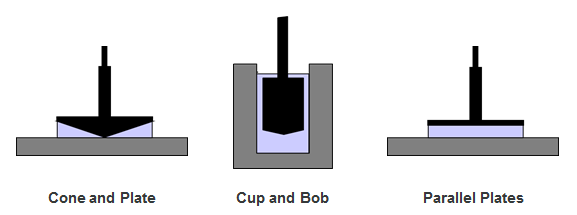

Malvern’s rheometer geometries are calibrated in an absolute way and so will give the correct (and same) results for a well-behaved sample across different instruments. These standard geometries include cone and plate, parallel plate or cup and bob, and many others which come in different sizes and surface finishes. Which type, size and surface finish is required largely depends on the shear rate range of interest and the sample type.

As a rule of thumb, if a very low viscosity sample (e.g. water or milk) is to be measured at low shear rates, we ideally use a measuring system with a large surface area to maximize the torque response from the applied shear rate. This need for a large surface area however is less important for higher shear rate measurements, where the stress and torque will be higher anyway. At higher shears, avoiding turbulence is key, and so it’s necessary to use a geometry with a narrower gap. There are geometries ideal for this, having both a large surface area and a narrow gap, such as narrow angled cones or parallel plates (eg Cone 1°/60mm, Plate 60mm).

Conversely, thicker samples are normally tested with a smaller cone or plate system to ensure that the instrument’s torque range best overlaps with the required stress range. Solid samples (such as plastic and rubber strips) are usually tested in a torsional clamp fixture where a long strip is clamped at both ends. Using these torsional fixtures, samples even as hard as glass or steel can be tested accurately.

In addition to the sample viscosity or modulus, we need to consider the presence of any large particles in the sample which may cause noisy and erroneous data if the gap is too narrow. As a general rule the gap should be at least 5 to 10 times the size of the largest particles otherwise the correct viscosity of the material is not being measured. If the particle size is very large (visibly lumpy) it would be better to use a cup and bob system with a wide gap than cone and plate or parallel plates.

Another key consideration is temperature since viscosity is usually temperature dependent. Any errors in temperature will, therefore, give errors in viscosity, particularly for oil based liquids which are more temperature sensitive. For these samples, a thermal enclosure should be used during measurement to prevent temperature gradients in the sample.

For samples prone to sedimentation, a cup and bob geometry (also known as a Couette geometry) is generally better, as settling occurs in a direction parallel to the geometry so particle concentration close to the geometry surface is relatively constant. For cone-plate or plate-plate, settling occurs in the direction perpendicular to the upper geometry surface and hence the concentration depletes over time with a consequent drop in measured viscosity.

Even in the absence of significant settling, there are often issues with measuring dispersions due to an effect called ‘wall slip’. This occurs because the concentration of the dispersed phase close to the geometry surface is lower than in the bulk and can result in the viscosity being underestimated. Wall slip can be counteracted in a number of ways, most notably by the use of roughened or serrated geometries which effectively take the geometry motion into the bulk of the sample and thus maximize sample-sample interactions at the expense of sample wall interactions.

Other than choosing the best measuring system, some other factors can also be important to generate good viscosity data. For instance, for equilibrium measurements, the delay time needs to be long enough for a steady viscosity value to be attained.

As can be seen from the chart below on the left, the viscosity of a shear thinning sample takes some time to reach an equilibrium value. This depends clearly on the sample’s structure and shear conditions applied – usually a viscoelastic sample at lower shear rate takes longer to reach equilibrium than a Newtonian sample for instance.

We can define the equilibrium conditions in terms of a “steady-state tolerance”, where the steady state is defined as dlogJ/dlogT, which is the rate of change of sample compliance (J) with time (where J = shear strain / shear stress). A steady state value of 1.000 shows that the material is at perfect equilibrium, a value lower than 1 indicates that the viscosity is increasing and a value higher than 1 indicates the viscosity is decreasing. Often when shear is initially applied to a sample, the viscosity takes a while to fall to an equilibrium and so the steady state starts above 1, but as time progresses it slowly comes to 1. Conditions can be set to determine when steady state is met, for example, a steady-state tolerance of +/- 0.02 (indicating that 0.98 to 1.02 is steady enough) and an acceptance time of 5 seconds may be a suitable starting point.

Other factors to consider

Sample drying or skinning at the surface – Best to use a solvent trap for volatile samples or samples prone to drying such as solvents or pastes respectively.

Sample fracture – Viscoelastic samples can be prone to fracture at higher shear rates due to elastic instabilities, this is often accompanied by an increase in Normal Force (measured on the upper plate) and a decrease in viscosity. If time permits, it’s good to watch the sample through at least one run to ensure that the sample is staying in the gap.

Bearing all of these things in mind, you should be well on your way to generating good reliable viscosity data! We hope you have every success in using your instruments, and are available for technical support or testing advice if needed. Please feel free to contact us to learn more!

Related post:

- Viscosity flow curve. Part 1

- Demo at Your desk: Kinexus Rotational rheometer

- Rheology explained. Part 1 – flow and viscosity