Aluminum food lakes are oil dispersible colorants manufactured by combining food dyes with alumina. Alumina absorbs the water-soluble colors and acts as a carrier vehicle for the dye. Aluminum consumption is a potential food safety concern. For example, the European Food Safety Authority (EFSA), in its opinion of 22 May 2008 (2) recommended lowering the tolerable weekly intake (TWI) for aluminum to 1 mg/kg body weight/week. Therefore quantification of aluminum in food dyes provides a way to monitor the potential for human intake. This note describes the measurement of Aluminum in food lakes by XRF using the fused bead method.

Please login or register to read more.

Aluminum food lakes are oil dispersible colorants manufactured by combining food dyes with alumina. Alumina absorbs the water-soluble colors and acts as a carrier vehicle for the dye. Aluminum consumption is a potential food safety concern. For example, the European Food Safety Authority (EFSA), in its opinion of 22 May 2008 (2) recommended lowering the tolerable weekly intake (TWI) for aluminum to 1 mg/kg body weight/week. Therefore quantification of aluminum in food dyes provides a way to monitor the potential for human intake. This note describes the measurement of Aluminum in food lakes by XRF using the fused bead method.

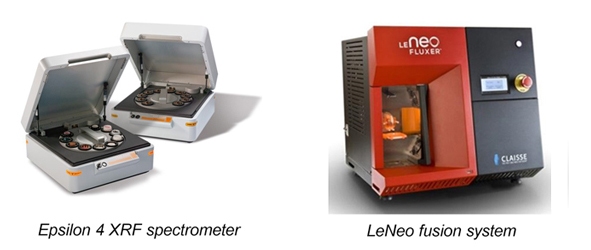

Measurements were performed using an Epsilon 4 EDXRF spectrometer, equipped with a 50 kV silver anode X-ray tube, six filters, and a high-resolution silicon drift detector. All calibrations were made using the system software.

A practical problem in XRF is the selection of suitable calibration standards. There are no commercially available analyzed aluminum lakes suitable for use as calibration standards. Thus, secondary standards were made by analyzing purchased lake specimens by WDXRF using the fused bead method for aluminum using a Zetium WDXRF.

The Malvern Panalytical fused bead calibration WROXI (Wide Range Oxide analysis method) was used to analyze the lake specimens used for calibration. WROXI is based on loss eliminated matrix correction and thus the organic part of the materials which burns off during fusion is counted as loss on ignition. This WROXI program had been modified to include additional elements including Cl.

The analyzed beads were then developed into a secondary calibration on the Epsilon 4 which was used to measure unknown samples. Elements other than Al2O3 were included because they are present and for matrix correction.

The fused beads were made using a Claisse LeNeo fusion system.

| Al2O3 % | CaO % | Cl % | Na2O % | P2O5 % | SO3 % | |

|---|---|---|---|---|---|---|

| Standard 01 | 91.1 | 0.0 | 0.0 | 0.3 | 0.0 | 0.0 |

| Standard 02 | 101.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| Standard 03 | 46.3 | 0.0 | 1.5 | 0.3 | 0.0 | 9.2 |

| Standard 04 | 46.5 | 0.0 | 1.5 | 0.3 | 0.0 | 9.1 |

| Standard 05 | 46.7 | 0.0 | 2.1 | 0.8 | 0.0 | 7.5 |

| Standard 06 | 46.4 | 0.0 | 2.1 | 0.8 | 0.0 | 7.7 |

| Standard 07 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| Standard 08 | 0.0 | 0.0 | 0.0 | -0.1 | 0.0 | 0.0 |

| Standard 09 | 2.3 | 2.5 | 0.1 | 0.5 | 0.6 | 0.1 |

| Standard 10 | 2.2 | 2.4 | 0.1 | 0.4 | 0.6 | 0.1 |

| Standard 11 | 32.2 | 0.0 | 0.4 | 0.1 | 0.0 | 6.6 |

| Standard 12 | 32.4 | 0.0 | 0.5 | 0.1 | 0.0 | 6.5 |

| Standard 13 | 41.8 | 0.0 | 0.5 | 0.4 | 0.0 | 1.1 |

| Standard 14 | 42.0 | 0.0 | 0.5 | 0.4 | 0.0 | 11.4 |

| Standard 15 | 43.4 | 0.0 | 0.9 | 0.3 | 0.1 | 12.6 |

| Standard 16 | 43.5 | 0.0 | 0.9 | 0.3 | 0.1 | 12.6 |

| Standard 17 | 41.3 | 0.0 | 2.0 | 0.1 | 0.0 | 11.5 |

| Standard 18 | 41.0 | 0.0 | 1.9 | 0.1 | 0.0 | 11.1 |

Three measurement conditions were used to measure the lake specimens. The instrument measurement time was just less than 9 minutes per sample.

| Condition | kV | uA | Filter | Time (sec) |

|---|---|---|---|---|

| <F-Si> | 5 | 3000 | None | 300 |

| <P-Cl> | 9 | 1666 | Ti | 60 |

| <K-V> | 12 | 1205 | Al-50 | 60 |

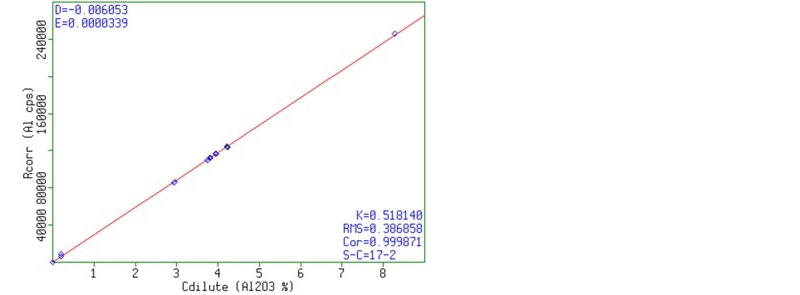

The fused bead calibration for Alumina in lakes shows a good correlation between the calculated concentrations and the measured intensities.

Fused bead calibration curve for Alumina in lakes

This calibration was used to conduct an instrument precision test. A sample of known concentration was measured 30 times using the final calibration. The one standard deviation results are excellent.

| Average | 1 SDev | Expected | |

|---|---|---|---|

| Al2O3 % | 46.5 | 0.05 | 46.7 |

| SO3 % | 7.6 | 0.01 | 7.7 |

| Cl % | 2.2 | 0.00 | 2.1 |

| Na2O % | 0.8 | 0.02 | 0.8 |

| CaO % | 0.04 | 0.00 | 0.03 |

| P2O5 % | 0.0 | 0.0 | 0.0 |

The aluminum content plus other constituent elements in food color lakes can successfully be measured using an Epsilon 4 benchtop EDXRF.

Using the fused bead method in combination with WROXI enabled the development of secondary standards for use in calibration. These secondary standards can then be used to develop pressed powder analysis methods.

Doing routine XRF analysis requires a robust sample preparation method and suitable standards. This data shows that these types of materials can be satisfactorily calibrated for and measured using the Epsilon 4.

Acknowledgment: Malvern Panalytical would like to thank Dr. Lili He and Haochen (Andy) Dai from the University of Massachusetts Amherst Department of Food Science for their collaboration on this project.