Nanoparticles can be difficult to produce, and are often synthesized in small quantities and dispersed in expensive solvents. The Hydro SV is allows us to measure the particle size distribution samples dispersed in 6-7ml of dispersant, and is therefore ideally suited to the measurement of nanoparticles by laser diffraction. This application note discusses the measurement of two nano-sized pigment samples using the Mastersizer 3000 and Hydro SV, highlighting the capability of the technique in resolving small differences in the particle size of the samples.

Nanoparticles are an increasingly important class of materials with wide-ranging applications in catalysis, coatings, pigments, cosmetics, electronics, food and medical industries. The physical and chemical properties of nanoparticles are highly sensitive to particle morphology, including particle size. These materials may only be synthesized in small quantities and are difficult to produce. Therefore it is often desirable to make particle size measurements from only a few milligrams of material and to be able to recover the sample after measurement for further testing. The Hydro SV accessory meets the requirements for measuring nanoparticles as it is a wet dispersion unit comprising a 7ml cuvette with magnetic stirrer, from which the sample can be recovered easily.

The unusual properties of nanoparticles occur as a result of their high surface area, which correlates directly with small particle size. Further control of the size and shape can fine-tune the material properties, including reactivity and surface chemistry, optical properties, magnetism, conductivity and permittivity.

Various techniques can be used to measure nanoparticle size. Laser diffraction is unique in possessing a large dynamic range, allowing the same equipment to analyze nanoparticles and much larger particles in one measurement. This is advantageous for situations where more flexibility is required in the laboratory, for example the characterization of nanoparticles added to bulk powders in the fine chemical industry, or when the milling and dispersion of the nanoparticles needs to be monitored.

The principle challenge when measuring nanoparticles by laser diffraction is to ensure the precision and resolution of the result. Precision is a function of repeatability and resolution can be deduced from the ability to separate data from samples of a similar size.

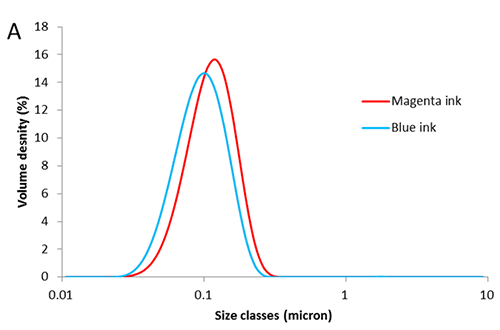

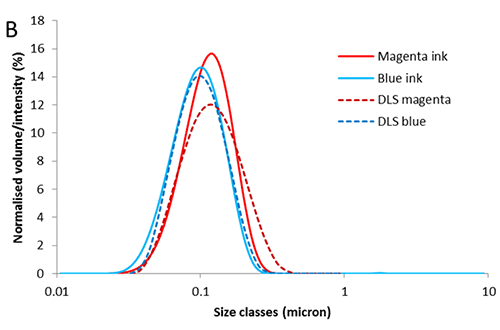

Two samples of nanoparticulate ink were measured to demonstrate the resolution and precision of the laser diffraction measurement. These samples were characterized previously by dynamic light scattering and are known to have median sizes approximately 20nm apart and overlapping particle size distributions.

The particle size distributions of the magenta and blue inks are predominantly Gaussian, with a small tail of fines (Figure 1A), and while the particle size distributions overlap, the median values are clearly resolved. To verify the difference in size between the two samples, particle size distributions were also measured using dynamic light scattering, DLS. The particle size distributions for both samples measured by both techniques are compared in Figure 1B, and the percentiles of the distributions are shown in Table 1A. For the blue ink, the size distributions overlap and there is excellent agreement between the Dv10, Dv50 and Dv90. The magenta ink shows good agreement between the size distributions, although DLS measures a slightly larger Dv90 which may be due to the different sensitivities of the two techniques.

|

|

| A | Dv(10)(µm) | Dv(50)(µm) | Dv(90)(µm) | |||

|---|---|---|---|---|---|---|

| Diffraction | DLS | Diffraction | DLS | Diffraction | DLS | |

| Magenta | 0.067 | 0.065 | 0.113 | 0.118 | 0.179 | 0.217 |

| Blue | 0.055 | 0.059 | 0.096 | 0.099 | 0.157 | 0.166 |

| B | Dv(10)(µm)

ISO 5% | Dv(50)(µm)

ISO 3% | Dv(90)(µm)

ISO 5% |

|---|---|---|---|

| Magenta 01 | 0.0665 | 0.113 | 0.179 |

| Magenta 02 | 0.0671 | 0.113 | 0.178 |

| Magenta 03 | 0.0665 | 0.113 | 0.179 |

| Magenta 04 | 0.0651 | 0.112 | 0.180 |

| Magenta 05 | 0.0679 | 0.113 | 0.178 |

| Mean | 0.0666 | 0.113 | 0.179 |

| 1xStd Dev | 0.00104 | 0.00040 | 0.00090 |

| 1RSD(%) | 1.56 | 0.318 | 0.501 |

It is also important to assess the precision of the measurements. As particle size decreases the forces of adhesion between the particles increases. Therefore, achieving good particle size results for nanoparticles will also depend on the sample’s state of dispersion and the stability of that dispersion. Hence, by making several measurements of each sample we can assess the stability of the dispersion. Table 1B shows the PSD percentiles for five repeat measurements of the magenta sample, as well as the variability (%RSD) of these measurements. This variability is well within the acceptable repeatability limits set out in the ISO standard for laser diffraction [1] of 5% on the Dv10 and Dv90 and 3% on the Dv50.

Two nanoparticle samples with Dv (50) values only 20nm apart were measured by laser diffraction using the Mastersizer 3000 and Hydro SV dispersion unit. The values obtained were close to those obtained by dynamic light scattering. This demonstrates the capabilities of the Mastersizer 3000 and Hydro SV for obtaining accurate and precise measurements of nanoparticle particle size, enabling the material properties of the nanoparticles to be controlled.