Processing of natural polymers can directly affect their characteristics, such as molecular weight, molecular weight distribution, size, and most importantly, conformation. By using the triple detector chromatography, changes in molecular structure and molecular chain length can be simultaneously and independently monitored.

The polysaccharides were dissolved in an aqueous buffer for an extended period of time under agitation. The polysaccharides were injected at a concentration around 5 mg/ mL for all the samples with an injection volume of 50 μL. The isocratic flow rate was 0.7 mL /min. The separation was carried out on a single PWxl column measuring 7.8 mm ID and 300 m m in length

The starches were dissolved in dimethylsulfoxide (DMSO) at a concentration around 0.5% by weight. The injection volume was 50 μL. The flow rate for the DMSO was 0.7 mL /min. The separation was done by two linear SDVB mixed bed columns columns in series.

|

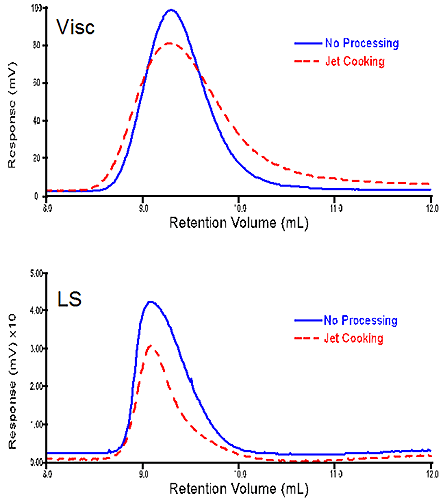

Jet cooking starches can greatly affect their molecular weight distributions. Jet cooking reduces both the overall viscosity and molecular weight, as shown in figure 1. Figure 1a shows the intrinsic viscosity overlay of the solubilised starch before and after jet cooking. In this normalized curve the jet cooking in shown to decrease the viscometer signal. Figure 1b shows the effect on the light scattering signal. Since the signal if proportional to the concentration and the molecular weight, it is clear that the molecular weight decrease upon jet cooking as the same amount of material was injected for both starches.

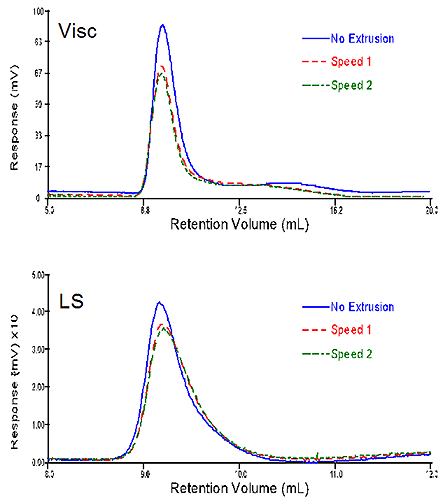

Similar to jet cooking, the single screw extrusion process can change the physical properties of a macromolecule. Here, it is shown that the extrusion rate (shear rate) makes little or no difference compared to the extrusion process, itself. Viscosity monitoring is more commonly done to measure polymer degradation and is shown in figure 2a along with the light scattering profile, figure 2b. The texture of the extruded starch is function of the molecular weight distribution. In this case, it is shown that the extrusion changes the viscosity and the molecular weight of the starch, possibly due to the high temperature process. The extrusion speed does not change properties of the starch as can be seen in figure 2.

|

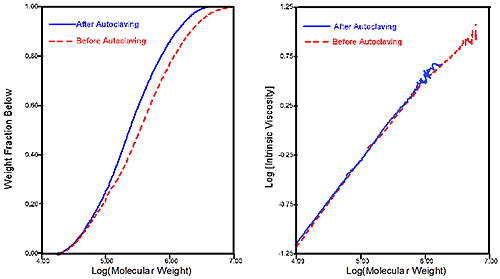

Polysaccharides are used in, for example, medical products. One reason for the addition of the polysaccharides to medical products is to give the medical products a higher viscosity. Autoclaving is a method of heat treatment used to sterilize materials which may affect polymers. The plots shown in figure 3 compare molecular weight and structure of a sample before and after autoclaving. It is clear that in this particular processing, the high molecular weight polymer end is greatly reduced. However, the polysaccharide structure remains virtually unchanged after autoclaving as shown by the overlapping Mark-Houwink plot in figure 3a. In this way, chain length and structural differences may be examined independent of one another.

|