Overview

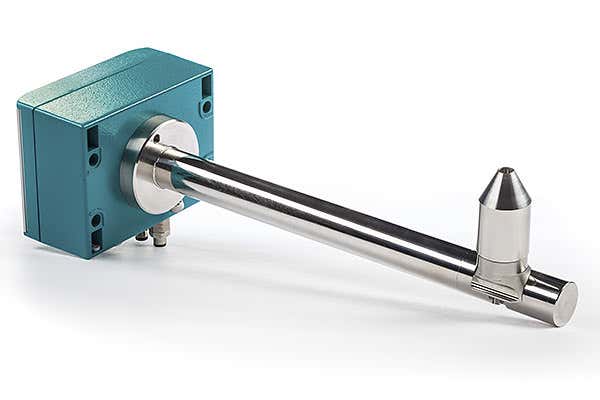

Easily slotted into a Parsum probe the D11 in-line eductor uses a single air supply introduced via three separate connections to apply suction, acceleration and thinning to the sample. It has an 8 mm aperture for sample flow and requires an 85 mm free opening for installation. A back flush function prevents material build-up, even for powders prone to adherence.

- Back flush function to prevent build-up for long-term trouble-free operation.

- Triple air supply to ensure sample is robustly presented in an optimal state for measurement.

How it works

The D11 disperser ensures robust and accurate particle size measurement with a Parsum probe in streams carrying coarse particles at high solids loadings. Using air it continuously dilutes mixes and transports samples drawn from the process. The air is introduced via three separate inlets to ensure a well-mixed sample that flows optimally through the measurement zone. Back flushing prevents any material build-up within the disperser giving reliable operation over the long term.

A 4-channel air supply unit is required for operation.

Specification

Disperser with 3 ring injectors, diluter and back flush function. 8mm opening with 3 external and 1 internal air connections.

System

| Pulsation | Yes (to No. 3 only). |

|---|---|

| Particle size | 1000 to 4000µm |

| Dv(50) | 50 to 1200µm |

| % Fines in product | Low to medium |

| Applications | Coarse particles and high solids loadings |

| Air flow l/min | 1 = 16 2 = 21 3 = 8 Internal = 8 |

Operating environment

| Temperature | -10°C – 100°C |

|---|---|

| Humidity | 35% - 80% non-condensing |