Features and benefits

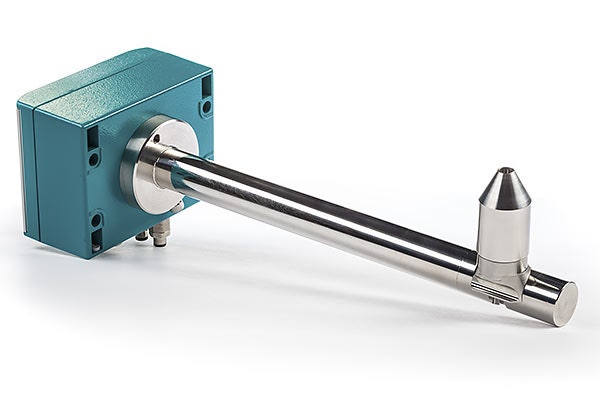

Parsum IPP 70-S is the standard instrument option. Used in the chemical, food and pharmaceutical industries for endpoint detection, process control/optimization and real-time QC, it is applied in unit operations such as grinding, agglomeration, granulation, sieving and spray drying.

- Lightweight and easy to install for rapid integration into new and existing processing plant.

- Wide dynamic range for particles from 50 - 6000µm travelling at up to 50m/s.

- Reproducible measurement at high solids loadings even with irregularly moving particles - ideal for fluidized bed monitoring.

- Real-time measurement and feedback via comprehensive, customizable software.

- No sampling or calibration required.

- Range of accessories enables application for abrasive, greasy, sticky and adherent particles.

How it works

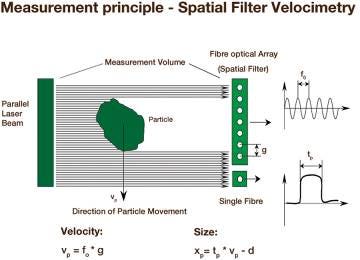

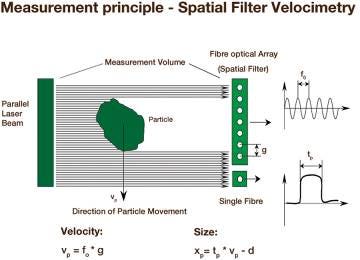

The Parsum IPP 70-S probe uses the well-established measurement principle of spatial filter velocimetry. No calibration or sampling is required and there is no assumption that the particles are spherical.

Spatial filter velocimetry is a number-based, chord length sizing method that collects data for individual particles to develop a particle size distribution.

Particles falling through a laser beam cast a shadow, interrupting the flow of light to a linear detector array made up of optical fibers. Particle velocity is calculated from the sequential interruption of linearly neighboring fiber elements of the spatial filter detector.

Particle size

is determined using a secondary signal, the pulse signal, which is a measure of the length of time for which the particle blocks a single optical fiber.

Measuring a large number of particles generates statistically valid results from which various size parameters and volume-based distributions are derived, depending on the needs of the user.

The Parsum IPP 70-S is installed directly into the line or vessel. Although no sample preparation is required, an internal compressed air supply can be used to disperse agglomerates, to keep the flow channel and optics clear of adherent material and to enable measurement at high solids loadings and temperatures.

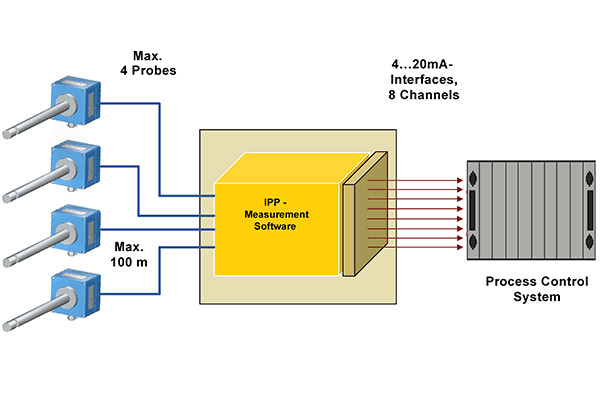

Information is transferred from the measurement zone to the electronic housing of the probe via fiber optic cable increasing instrument robustness. These data can then be transferred to the control room or indeed into an existing control system for processing monitoring and control. Because the instrument provides a measure of concentration in the sensing volume, changes in flow/throughput can be estimated, using an appropriate correlation.

Support

Protect your investment and ensure optimized performance at all times with Malvern Panalytical's service plans.

When you purchase a Malvern Panalytical product we understand that this is just the first stage of a working relationship that will last for the lifetime of the instrument. Depending on your needs, Malvern Panalytical will provide the support for your business.

Help Desk

- Telephone and email support.

- Operators who take responsibility for your call and ensure your query is answered.

Training

Software downloads

Malvern Panalytical's service options- choose the right plan for you:

Malvern Panalytical Platinum Plan

For laboratories where maximizing instrument up-time is critical to its daily performance. Our highest level of response and the 'all inclusive' price plan takes care of those unexpected repair bills should the unfortunate occur.

Malvern Panalytical Gold Plan

Enhance your laboratory productivity by maintaining instrument efficiency. Still receive that priority response, combined with specialist technical and software support, we'll keep your instrument performance on track to deliver.

Malvern Panalytical Bronze Visit

For laboratories looking to optimize instrument performance, regular preventative maintenance is essential.

| Platinum Plan | Gold Plan | Bronze Visit |

|---|

| Annual PM/PV Test | | | |

| Telephone / Email Support | | | |

| Priority Response | | | |

| Emergency Breakdown visits* | | | |

| Parts Included | | | |

| Technical & Software Support | | | |

| IQ/OQ (Pharma)*** | | | |

*including labour & travel costs ***available at an additional cost