Cryostat I

The Micromeritics Cryostat I is a single-stage cryogenic refrigerator based on the Gifford-McMahon principle, designed to work with the 3Flex.

The Micromeritics 3Flex offers porosity, chemisorption, surface area and temperature-programmed methods.

The 3Flex, a high-performance gas adsorption analyzer from Micromeritics, is the most advanced instrument for measuring pore size, pore volume and surface area of powders and particulate materials.

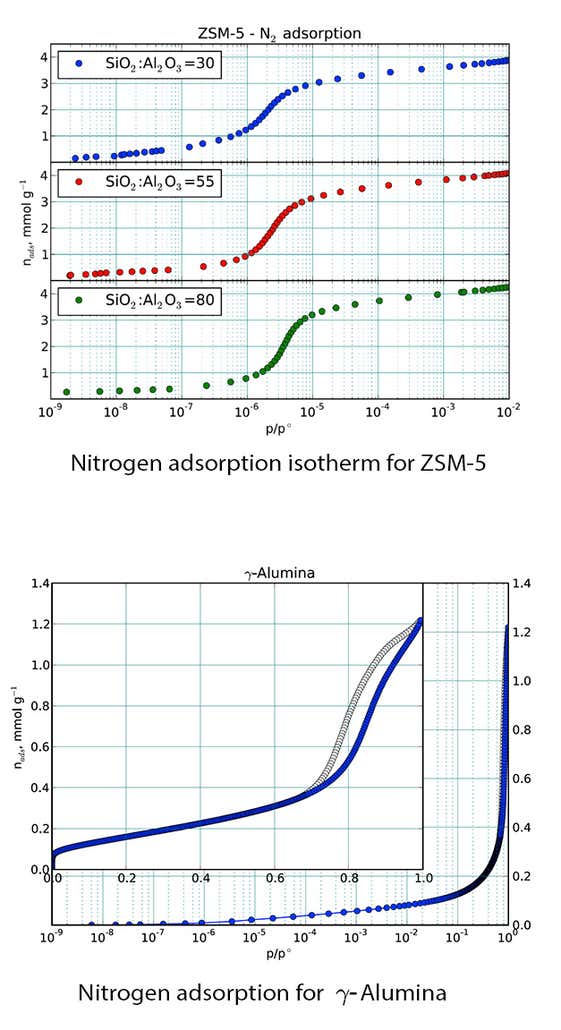

Suited for gas or vapor adsorption analysis of microporous (<2 nm) and mesoporous (2 to 50 nm) materials, the 3Flex delivers superior accuracy, resolution and data reduction.

Standard methods or user-customized protocols can be used to characterize adsorbents, catalysts, zeolites, MOFs, APIs, excipients, and a wide variety of porous and non-porous materials.

Extend your 3Flex to physical and chemical adsorption methods with our chemisorption configurations. Ideal to characterize the texture and active surface of catalysts, catalyst supports, sensors and a variety of other materials.

The Micromeritics 3Flex features three parallel analysis ports. One port is configured with an ultra-high sensitivity 0.1 torr transducer to enable characterization of the ultra-micropore region.

All three ports can be configured for micropore analysis to improve throughput for the most demanding labs.

The Flex is a single-port configuration option for the 3Flex, designed for labs with limited throughput needs in mind.

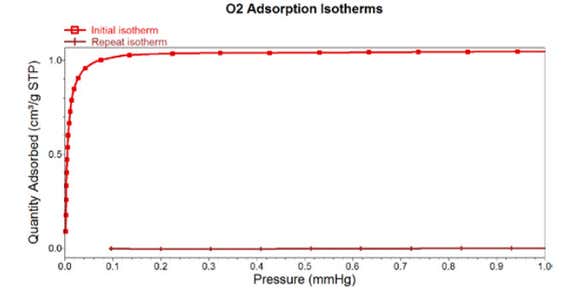

Go beyond micropore and extend your range of resolution to the ultramicroporous level. The advanced transducer technology and vacuum management of the Micromeritics 3Flex permits you to collect adsorption isotherms and the pore size distributions for materials with pores as small as 0.3nm. Plus, exclusive new pore size distribution models allow you to measure smaller pores, faster, using H2, O2, or CO2.

The Micromeritics 3Flex permits you to optimize experimental parameters to gain greater understanding of your material. The 3Flex has the capability to analyze a sample with 3 separate probe gases simultaneously, one on each analysis port, within a single run.

The Micromeritics 3Flex provides the highest quality isotherms: the widest range of pressures, the highest resolution, and the most accurate adsorption measurements. MicroActive provides the greatest number of peer-reviewed models for pore size distribution and surface texture. Together, you gain the most valuable insight into the structure and performance of your materials. Validate your theories and rationalize the design and synthesis of MOFs, zeolites, activated carbons and other products. The high throughput results from the 3-port mesopore & micropore design of the 3Flex empower you to rapidly characterize & understand surface area, porosity, and adsorption capacity of your high performance materials.

Recognized as the most advanced instrument in the field for material surface characterization, the 3Flex has become a crucial tool for providing high-resolution adsorption and desorption isotherms to advance and validate fundamental understanding into new material

The 3Flex is the premier platform for gas adsorption measurements, delivering a complete portfolio of capabilities for advanced physisorption measurements.

Expand the 3Flex’s analytical reach with chemisorption capabilities. Additional capabilities include: static chemisorption, dynamic chemisorption, and pulse chemisorption to measure specific surface chemistries.

With the addition of the integrated thermal conductivity detector (TCD), the 3Flex can deliver highly accurate dynamic chemisorption analyses: temperature programmed reduction (TPR), oxidation (TPO), desorption (TPD), and reactions (TPRx). Investigate temperature-dependence of specific adsorption or desorption process profiles for catalysts and adsorbents.

The TCD Loop option further unlocks pulse chemisorption for measurements of active surface area and an automated injection loop.

Innovative design allows a complete switch between physisorption and chemisorption analysis in minutes.

Physisorption configuration

Chemisorption configuration

Chemi-TCD configuration

Chemi-TCD Loop configuration

Empowering the Study of Energy Storage and Gas Separations by MOFs and POPs.

Determine the influencing relationship of surface area, pore volume and substrate/analyte interactions for uptake, capacity, and release evaluations: The 3Flex has the capability to analyze a sample with 3 separate probe gases simultaneously, one on each analysis port, within a single run.

Evaluate optimal small pore size as a strategy to enhance hydrogen–framework interactions: Superior gas management and temperature control permits accurate and precise micropore and ultra-micropore (<0.7 nm) measurements.

Advanced pore size analysis with NLDFT models: MicroActive™ data software permits you to graphically capture the desired range of isotherm data using an intuitive user interface. This reduces the time and effort required to transform data to textural information including surface area and pore size. The MicroActive user interface enables you to export data to your preferred software for further analysis or custom plotting, and the powerful reporting software includes exporting the data to a spreadsheet, saving to PDF, or printing reports.

Quantitatively determine the number of surface active sites for catalytic potential: Provide data related to monolayer uptake, metal area, dispersion and crystallite size of the catalysts. The advanced flexibility of the Flex family lets you quickly change from Physisorption analysis to Chemisorption analysis in minutes to permit full characterization in one instrument.

Determine if zeolite processing has resulted in loss of structure or degradation: The advanced architecture of the 3Flex provides industry-leading micropore resolution and provides information to help resolve minor structural defects due to processing. The advanced design of the 3Flex provides industry leading resolution and accuracy. Obtain valuable insight for pore architecture to gain greater understanding of transport, diffusion rates and selectivity.

Determine adsorption dynamics in regard to resident time for performance in fixed bed and flow through systems: Acquire valuable data for greater understanding of the influence of surface area and pore volume and pore size distribution on performance.

Gain valuable insight of structural and chemical heterogeneity influence on adsorption dynamics: Superior gas management, hard seal valves and metal seals along with precise temperature control permit accurate and precise micropore measurements. Evaluate temperature and chemical deactivation processes in regard to porosity and surface activity. Accurate temperature and gas control ensure repeatable analytical data sample to sample, batch to batch.

| Analysis range | 1.3 x 10-9 to 1.0 P/P0

1 x 10-6 to 900 torr |

|---|---|

| Parallel physisorption analysis ports | 3Flex: 3

Flex: 1 |

| Available micropore ports | 3Flex Physisorption only: up to 3

3Flex Chemisorption: up to 3, one port dual purpose chemisorption and physisorption |

| Dosing and evacuation control | Proprietary Servo valve

Dosing control by pressure or volume |

| Roughing pump | 4 stage diaphragm |

| Krypton analysis | Standard 1 port, optional up to 3 ports |

| Simultaneous analysis gases | Up to 3 gases concurrently, one probe gas on each port |

| Min. measurable surface area | Standard 0.01 m2 /g

Krypton 0.0005 m2 /g |

| Manifold temperature control | 45 °C, ±0.05 °C with 3 strategically placed RTDs |

| Adsorptive gas inlets | 3Flex physisorption only: 6

3Flex chemisorption: 12 standard; optional up to 16 |

| Vapor sorption | Ports 1 and 2: Standard

Port 3: optional with heated vapor source |

| Furnace | 3Flex physisorption only: N/A

3Flex chemisorption: Ambient to 1100°C, programmable from 0.1 to 50 °C/min |

| Mass flow controller | 3Flex physisorption only: N/A

3Flex chemisorption: Standard, flow up to 200 cm3/min |

| TCD & cold trap for TPx | 3Flex physisorption only: N/A

3Flex chemisorption: Optional |

| Automated loop | 3Flex physisorption only: N/A

3Flex chemisorption: Optional |

| Dedicated port (residual gas analysis by MS/FTIR) | 3Flex physisorption only: N/A

3Flex chemisorption: Included |

| Mass spec / external system software interface control | Included |

| Degas | 3 in situ, 6 additional with dedicated prep system |

| Pressure transducer system | Up to 12 |

| Transducer accuracy | 1000 torr 0.12% reading

10 torr 0.12% reading

0.1 torr 0.15% reading |

| Analysis range | 1.3 x 10-9 to 1.0 P/P0

1 x 10-6 to 900 torr |

|---|---|

| Parallel physisorption analysis ports | 3Flex: 3

Flex: 1 |

| Analysis range | 1.3 x 10-9 to 1.0 P/P0

1 x 10-6 to 900 torr |

|---|---|

| Parallel physisorption analysis ports | 3Flex: 3

Flex: 1 |

| Analysis range | 1.3 x 10-9 to 1.0 P/P0

1 x 10-6 to 900 torr |

|---|---|

| Parallel physisorption analysis ports | 3Flex: 3

Flex: 1 |

| Available micropore ports | 3Flex physisorption only: up to 3

3Flex chemisorption: Included |

Even with the best preparation, microporous materials may adsorb gas during the transfer form preparation to analysis stations. That is why the 3Flex includes an in situ sample tube heater to finish sample preparation at the analysis station to maximize accuracy for microporous and ultramicroporous materials.

The Micromeritics Cryostat I is a single-stage cryogenic refrigerator based on the Gifford-McMahon principle, designed to work with the 3Flex.

The Micromeritics' Chiller Dewar is a closed-loop recirculation system, designed to work seamlessly with the 3Flex.

The Micromeritics' ISO Controller is designed for the 3Flex, and utilizes thermoelectric cooling based on the Peltier principle.

The Micromeritics FlowPrep lets you choose the most suitable gas, temperature, and flow rate for your application and sample material.

Specifically developed for conveniently filling Dewars for gas adsorption instruments, but also can be used for other cryogen applications.

The Micromeritics Smart VacPrep is an advanced six-port system that utilizes a vacuum to prepare samples by heating and evacuation.

The Micromeritics VacPrep features six degassing stations, and a choice of vacuum or gas flow preparation on each of the six stations.

The ultra-stable leak-free manifold design on the Micromeritics 3Flex provides the ideal environment for low pressure measurements, as low as 10-9 p/p0. Embedded temperature control to 45°C ± 0.05°C and measurement with three carefully positioned RTD’s ensures the highest gas volume accuracy.

The result is high accuracy isotherms over the widest range of analysis pressures, ensuring complete and reliable characterization from meso- to ultramicro-pore sizes.

Unique computer-controlled servo-valve technology ensures dosing accuracy, especially at low analysis pressures where traditional designs struggle to deliver accurate doses.

Advanced dosing controls allow for the seamless combination of dosing by pressure and volume increments. The result is the highest resolution isotherms with the shortest analysis time.

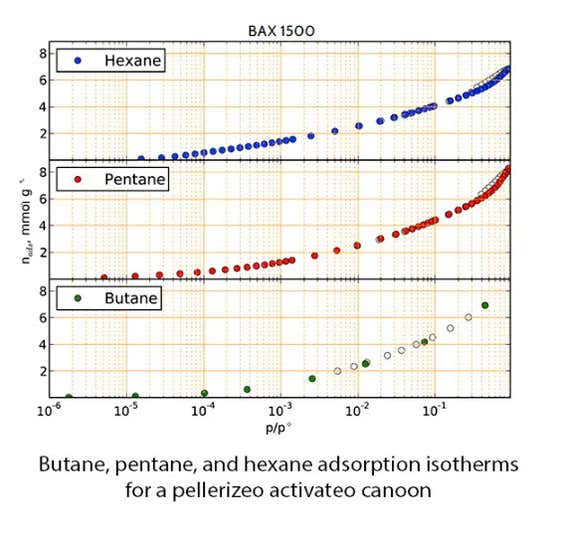

The Micromeritics 3Flex is ideally suited to studies of vapor sorption. Every instrument features a manifold that is controlled to 45 °C, ±0.05 °C to prevent condensation during vapor dosing.

An available heated vapor source extends the range of available analysis vapors. An extensive library of fluid properties for more than 80 fixed gases and vapors is included to maximize the analysis capabilities.

Isotherm data are easily collected using hydrocarbons as the adsorptive.

Advanced experimental controls allow you to easily design measurements that meet your needs for accuracy, speed, and experimental conditions.

For studies that require particularly aggressive gas compositions, a special version of the Micromeritics 3Flex is available with enhanced corrosion resistance (ECR).

To provide the greatest stability under the harshest working conditions, wetted materials are constructed from highly resistant Hastelloy, stable perfluoro elastomers, and inert-coated stainless steel.

Up to sixteen-inlet* gas manifold is standard with the chemisorption capability. Flow control during sample activation utilizes a mass flow controller (MFC) for precise and repeatable sample preparation.

The MFC is included with all chemisorption configurations.

*TCD with Loop configuration

In-situ preparation and activation provide a fully automated method that does not require user intervention and fully integrates activation and analysis into one simple-to-use application.

Flexible pre-treatment options allow for reduction, oxidation, evacuation, and purging.

MicroActive Data Reduction and Control Software is designed for the Micromeritics 3Flex, and includes:

The Micromeritics 3Flex interactive reports include:

The NLDFT Advanced PSD, Dual DFT modeling allows the user to combine the information gathered from nitrogen/argon and carbon dioxide, hydrogen, or oxygen isotherms to deliver a full pore size distribution on materials (such as carbon slit pores) where pores of molecular sizes are present.

This method's range of pore size analysis is extended to smaller pore sizes compared to the standard nitrogen analysis. This is because CO2, H2, and O2 can access ultra-micropores that are not accessible to N2 at cryogenic temperatures due to diffusion limitations.

The faster diffusion time of CO2 and H2 or O2 also means that overall micropore analysis time is reduced compared to a complete isotherm based on N2 or Ar.

This advanced NLDFT method allows you to determine the pore size distribution of your sample using two isotherms.

In this example (right), CO2 adsorption (green) at 77 K and N2 (red) are used to calculate a single pore-size distribution. You do not have to cut and paste distributions from CO2 and nitrogen - a single distribution is determined using both isotherms.

MicroActive for the 3Flex includes a powerful utility that permits you to construct a single pore size distributions from combined data from mercury porosimetry and gas adsorption measurements.

This new import function allows you to rapidly view micropore, mesopore, and macropore distributions in a single application.

Version number:

Please contact support for the latest software version.

The most advanced instrument for measuring surface area, pore size, and pore volume of powders and particulate materials. Upgrade your analysis today.