Available alumina and reactive silica define ore grade and conditions for bauxite refining. Malvern Panalytical’ s predictive solutions help to efficiently sort and blend bauxite, ensure optimal and profitable extraction of available alumina, and support sustainable and safe waste management (red mud).

Our expertise and solutions range from direct conveyor belt analysis to laboratory analysis and complete automated quality control. We deliver tailored analytical solutions for exploration geologists, mine planners, process engineers, laboratory and quality managers as well as geometallurgists.

Bauxite Mining

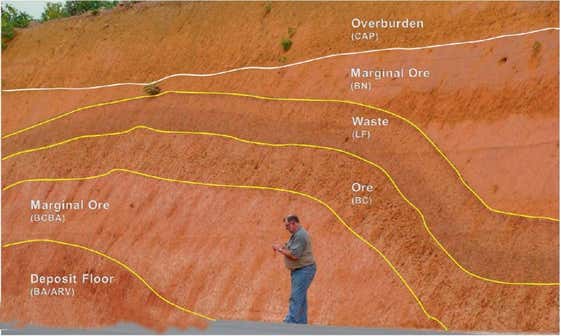

Prior to extracting bauxite ore, deposits must be evaluated to gain knowledge about the grade distribution within an ore body to optimize mine planning.

Malvern Panalytical’s analytical solutions enable grade definition directly in the field with mineralogical (NIR) and elemental (XRF) analyzers.

Epsilon 1 Mining

Real-time ore monitoring

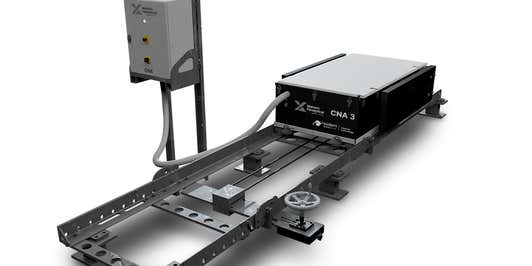

Our solutions for real-time monitoring on conveyor belts (elemental and mineralogical) with its fast feedback loops, enable fast counteractions on changing bauxite composition directly in the mine and effective ore sorting.

Optimal bauxite blends with constant composition secure optimal use of caustic soda and other reagents during refining and avoid costly processing of waste material. Control of the moisture content on the conveyor belt using near-infrared (NIR) technology, together with accurate monitoring of the composition of iron ore before shipment, guaranties constant ore quality to avoids penalties.

CNA³ elemental cross-belt analyzer

Analysis of major and minor elements in bauxite samples prepared as fused beads

Analysis technologies

Our laboratory solutions, tailored to the specific requirements of your mine, provide accurate and fast information whether it is benchtop or stand-alone equipment or completely automated laboratories.

Our expertise in XRF sample preparation, especially to produce high quality glass disks using fusion machines, are the basis for accurate elemental analysis according to international norms. The use of modern technologies such as X-ray diffraction (XRD) to predict available alumina and reactive silica, reduces the need for costly, time intense and unsafe wet chemistry.

The Minerals edition of Zetium

Aeris Minerals edition

Alumina refining

Epsilon 4 Mining & minerals

Assure optimal alumina quality impurity monitoring

Efficiency of alumina refineries, minimal use of energy per ton alumina and highest recovery rates depend on bauxite composition, impurity level of the process liquor and optimal caustic soda consumption. Our portable and flexible elemental analysers are perfectly suitable to monitor impurity levels of bauxite and process liquors directs in the refinery even in remote areas.

Particle size and distribution as well as the crystallographic modification are key variables that define quality of alumina and directly impact the rate of dissolution of alumina in the aluminium smelters. To meet the required alumina specifications our on-line particle size analyzers are designed to operate in rough process environments. Economic benefits are:

- Control of fines to avoid health, safety and environmental issues during transport

- Reduction of waste, energy consumption and manpower for manual measurements

- Avoid reprocessing “out-of-spec” material

Insitec range

Aeris Minerals edition

Waste management

Waste management is extremely important for sustainable and hazard free mining and refining of bauxite. Malvern Panalytical solutions support the frequent monitoring of particle size, mineralogy of an elemental composition of red mud to promote its settling and filtering properties and the optimal consumption of coagulants and flocculants.

Zetasizer range