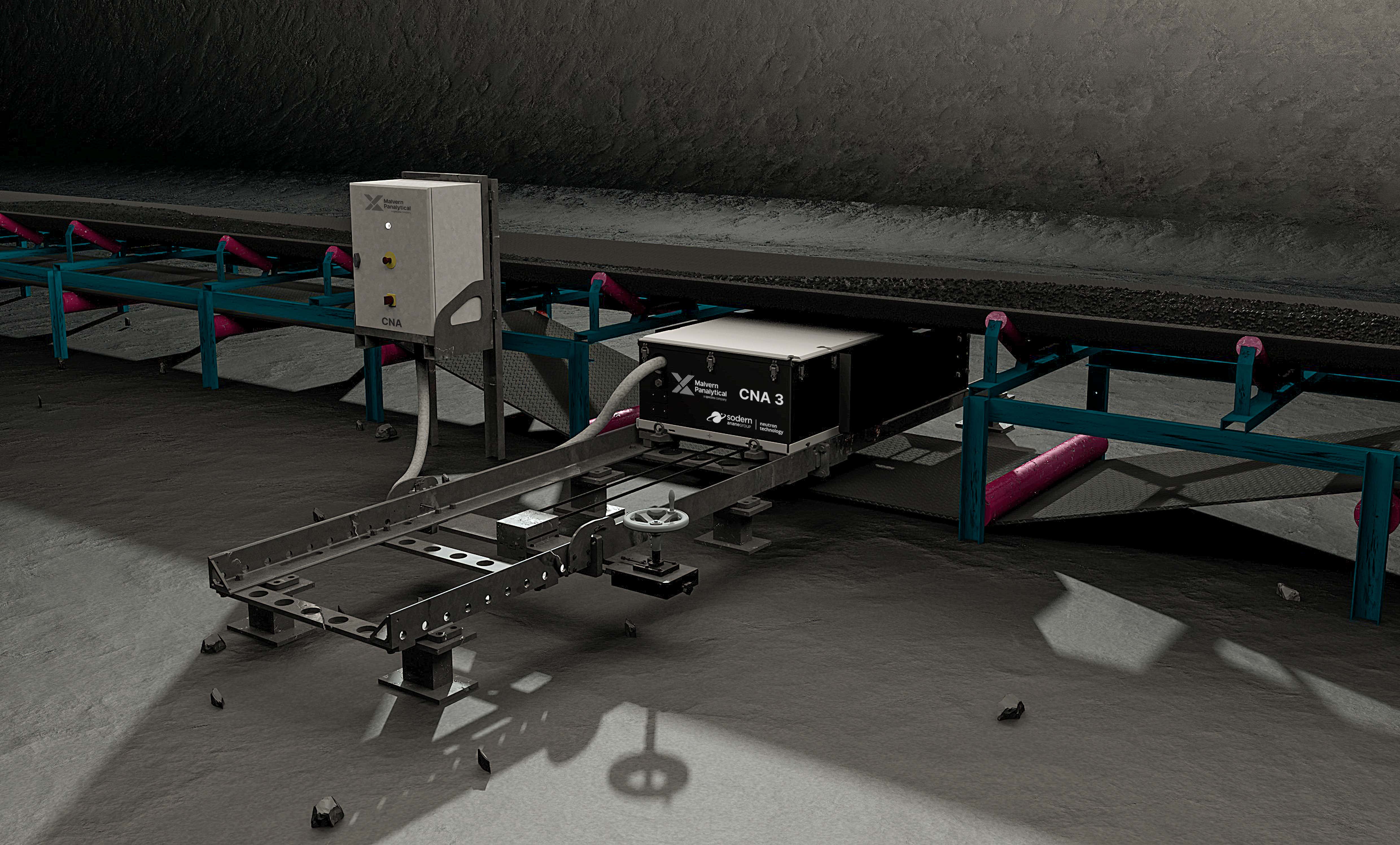

CNA³ is one of the latest generation of the CNA family. It has been entirely redesigned to be suitable for tough environments such as underground mines, but still features the cutting-edge Sodern neutron technology with unmatched lifetime and neutron output stability (PFTNA).

CNA³ provides high-frequency online elemental analysis of the bulk material on the belt. No sampling is required as material is measured in real time on the conveyor belt.

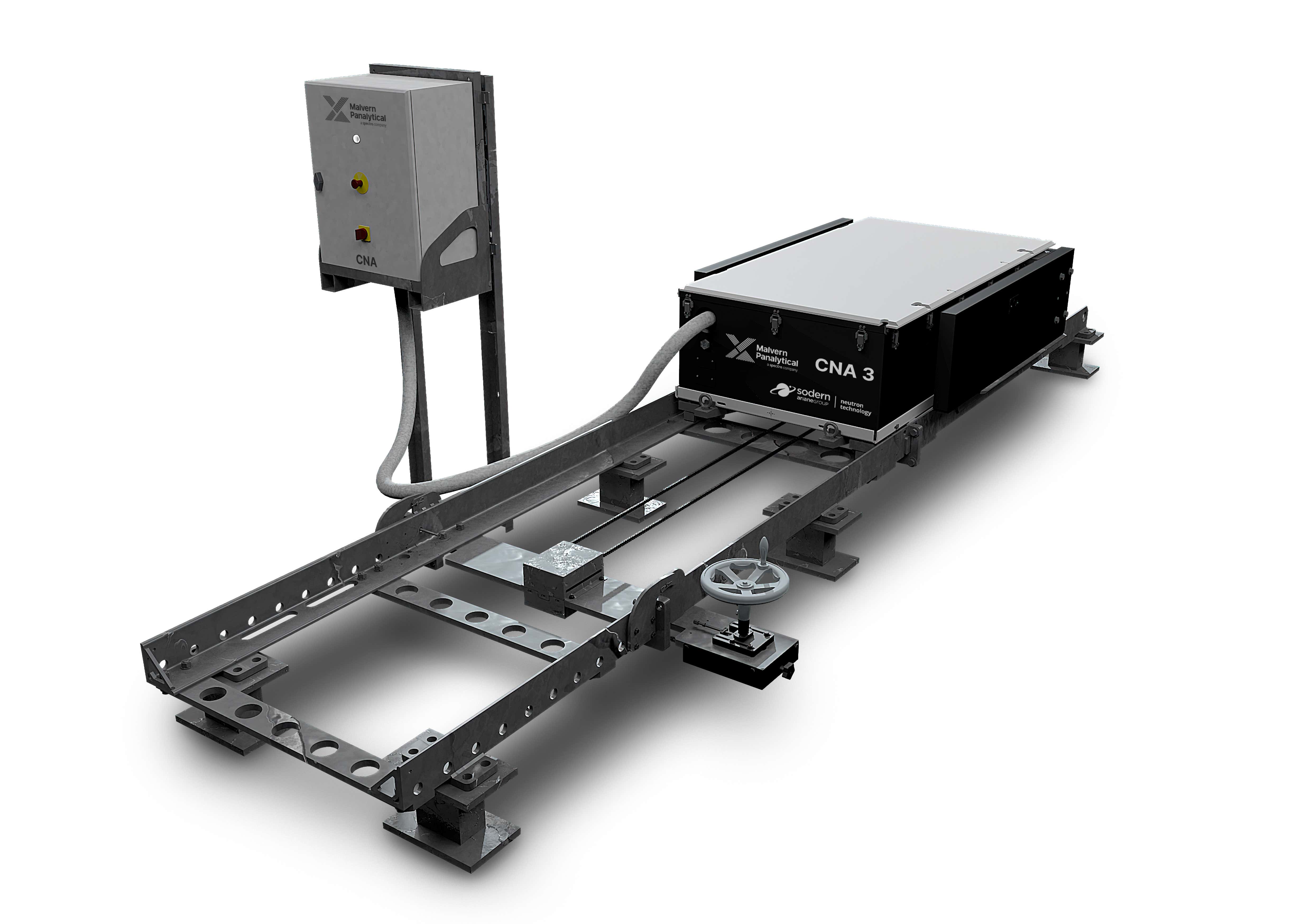

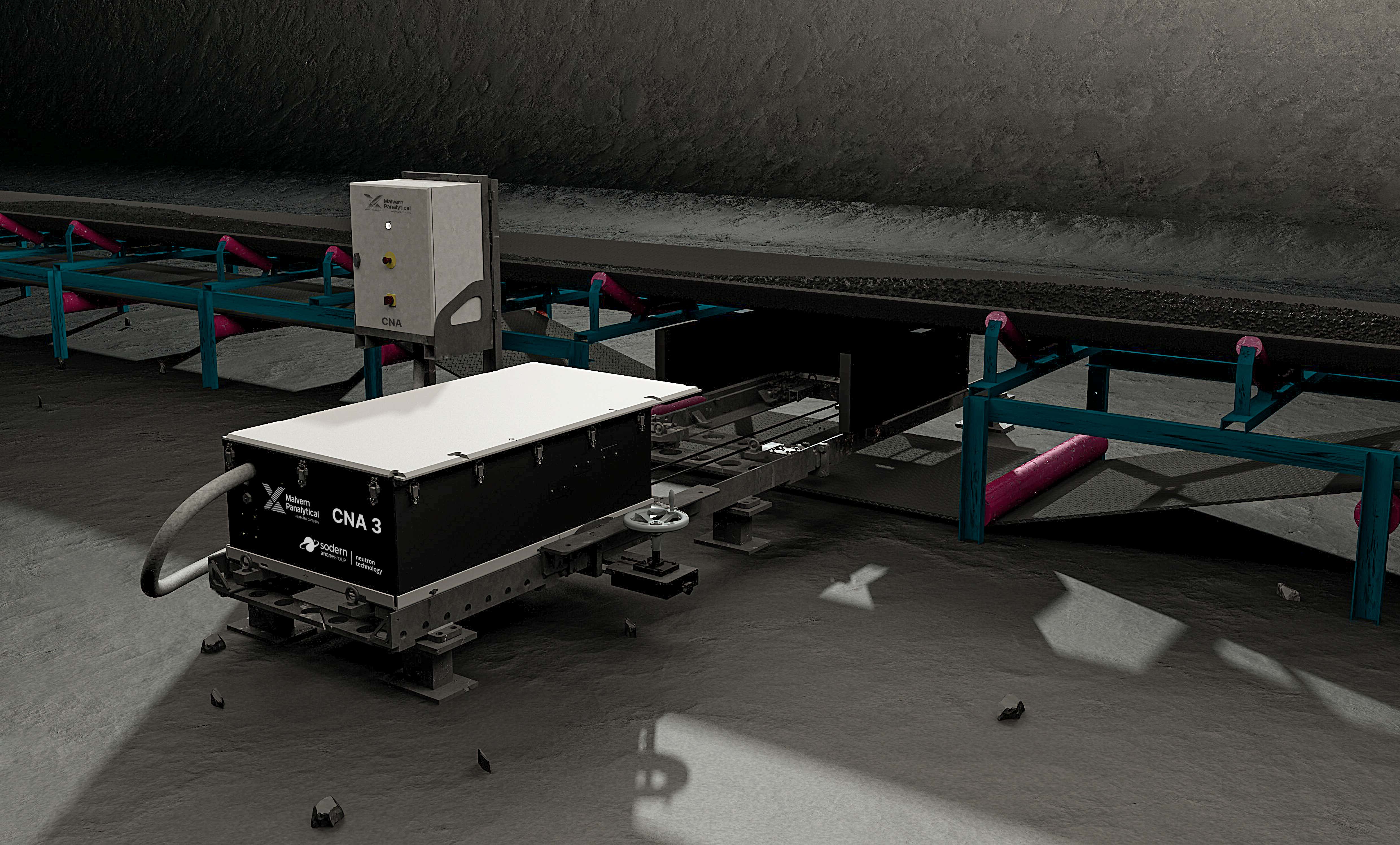

This compact and rugged design is completely underneath the belt - variation of belt load and particle size common in the mining industry doesn’t affect the performance of the system. This is a key design feature to provide stability and representativeness for an efficient process control.

Features

Added value

- On-off electric proven neutron source

- Constant neutron flow for unmatched performance stability

- Automatic radiation protection system (ARPS)

- Compact design for simplified installation and start up

- No material height limitation, everything is below the belt

- No sensitivity to belt load variation or particle size variation

- Available for extra-wide belt

Unique offline position

Mounted on a rail, a CNA³ can be easily moved to the side for maintenance, cleaning, neutron generator swap, etc. This position, also called offline position, gives our customers the unique opportunity to perform a sample measurement in order to check performances of the system and apply correction if necessary, without the need to stop production.

Applications

CNA³

Coal

Coal is an important industrial mineral both as a fuel and feedstock. Coal quality can vary greatly depending on the source, hence the usage and price are highly dependent on the composition.

Whether located directly at a mine, a coal processing plant, a metallurgical plant, a power plant or other usage point, the CNA³ can provide reliable real-time information on the coal composition, calorific value, ash content, volatile matter, and moisture. The CNA³ neutron generator technology enables measurement of a wide range of elements, including C and O.

Copper

The CNA³ design is particularly suited for conveyor belts carrying copper ore. The unit is designed to accommodate wide belts with variable loading and a wide range of particle sizes. With the entire unit below the belt, oversize material passes harmlessly over the analyzer. The unit provides elemental data for a wide range of elements. This data can be used to guide mining operations, sort material streams, and provide feed forward process control information.

Iron

With its large calibration range, the CNA³ can analyze a wide range of iron ore. The unit can be located deep underground or at ground level and can provide elemental information to guide mining operations and/or mix different ores to a target composition to reduce variability in downstream processes.

Nickel

Whether used at the mine or in downstream processing, the CNA³ can provide information to control nickel grade, Fe/Ni ratio, basicity index and other key process parameters. Powered by a neutron tube, the CNA³ provides a controlled neutron flux for stable operation and unmatched safety.

- Perform resources assessment

- Monitor key components for the mining operation

- Sort ore by element(s) of interest

- Optimize crushing operation

- Optimize magnetic separation

- Optimize leach pile composition quarry life

- Minimize flotation reagent consumption

Specification

Support

Services

Solutions to maximize the return on your investment

To assure that your instrument remains in top condition and performs on the highest level, Malvern Panalytical offers a wide range of services. Our expertise and support services assure an optimal functioning of your instrument.

Support

Service for a lifetime

- Phone and remote support

- Preventive maintenance and checkups

- Flexible Customer Care Agreements

- Performance certificates

- Hardware and software upgrades

- Local and global support

Expertise

Adding value to your processes

- Sample preparation development/optimization

- Analytical methodologies

- Turnkey solutions for XRD

- Operations via IQ/OQ/PQ, quality assurance (GLP, ISO17025) or round robins/inter laboratory studies

- Automation of lab processes

- Consultancy services

Training and education

- Training on-site or at our competence centers

- Broad range of basic and advanced courses on products, applications and software

Analytical services and calibration materials

- Expert (XRF) analyses services

- Oxides and trace analysis

- Customized calibration materials