Biologics manufacturing and quality control (QC)

Characterization tools to support biopharmaceutical manufacturing and production

Characterization tools to support biopharmaceutical manufacturing and production

Once a biopharmaceutical product has gone through scale-up and into production, many of the same biophysical characterization approaches used throughout development and formulation have a continuing role in ensuring conformance to manufacturing and quality specifications. The adoption of a Quality by Design (QbD) approach to development, with early definition of critical quality attributes and critical processing parameters, will ensure monitoring and control of identified biophysical properties, such as aggregation.

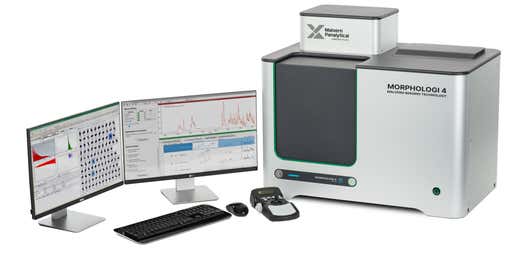

Malvern Panalytical systems are used in troubleshooting and root cause analysis, and to monitor batch-to-batch comparability or biosimilarity.

Differential Scanning Calorimetry (DSC) is used in research and development to identify biotherapeutics with good stability potential and to determine the conditions that maximize a biological product’s shelf-life. It also has a role in manufacturing, where it supports the robust demonstration of batch-to-batch comparability of any biologics, or the comparability of an innovator product with a biosimilar product.

An out-of-specification product requires investigation to understand the cause of the manufacturing issue and prevent any recurrence. This requires referencing the final dosage form back through the processes involved in its creation, to establish where the problem lies.

Biophysical characterization techniques play a key role in determining if and where there are issues with aggregation, for example, or in determining contamination sources.