Insitec 2000 installation guide (English)

Version number: MAN0311-06-EN-00

See the current Insitec range. Learn More

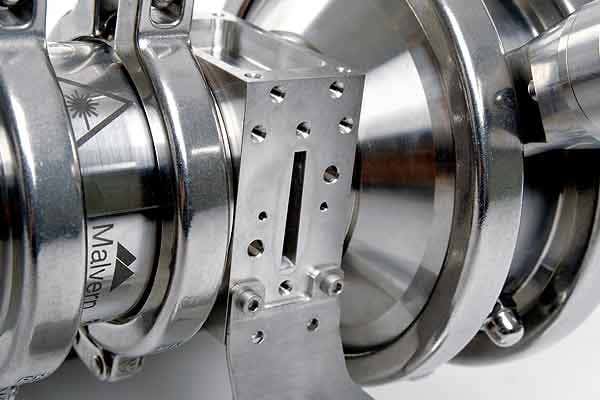

Learn MoreEngineered to withstand the rigors of the process environment, Insitec Wet particle size analyzers use laser diffraction technology to measure particles in the size range 0.1 to 2500 µm in emulsions, suspensions and slurries. Insitec Wet can be configured to suit practically every wet particulate process, delivering real-time monitoring and control 24/7.

Version number: MAN0311-06-EN-00

Version number: MAN0663-01

Version number: MAN0662-01-EN

Version number: MAN0484-02-EN

Version number: MAN0472-03

Version number: MAN0470-03-EN

Version number: MAN0471-03-EN

Version number: MAN0473-03-EN

Version number: MAN0304G-3-0

Version number: MAN0351G-2-0

Version number: MAN0304F-3-0

Version number: MAN0351F-2-0

Version number: MAN0304-3-1

Version number: MAN0440-1-1

Version number: MAN0375-1-0

Version number: MAN0467-1-0

Version number: MAN0468-1-0

Version number: MAN0466-1-0

Version number: MAN0311-04-DE-01

Version number: MAN0311-04-FR-01

Version number: OP-IPP70-nov11

Version number: HW-IPP70-nov11

Insitec 2000 RT Sizer software

Insitec 2000 RT Sizer software

Insitec 2000 RT Sizer software

Malvern Link II Software

Malvern Link II Software

Malvern Link II Software

Malvern Link II Software

Malvern Link II Software

Malvern Link II Software

Malvern Link II Software

Bug fix enabling updates to IMDdata values from WinWrap script in customer data converter

Malvern Link II Software

A range of Insitec Wet options meets the specific requirements of different process applications.

A continuous laser diffraction particle sizing solution with integrated, automated concentration control for monitoring concentrated wet process streams. Suitable for measuring particles in the size range 0.1 to 2500µm in solid-liquid or liquid-liquid streams.

Engineered to withstand the rigors of the process environment, Insitec Wet for pharmaceutical industry applications provides a robust, proven PAT solution for measuring particles in the size range 0.1 to 2500 µm. Insitec Wet laser diffraction analyzers can be configured to suit practically every wet particulate process, delivering real-time monitoring and control 24/7, with options for:

An ATEX approved, intrinsically safe laser diffraction particle size analyzer for process monitoring in gas or dust zoned hazardous environments rated as zone 0, 1 and 2, or 20, 21 and 22. Suitable for measuring particles from 0.1 to 2500µm, it can be configured to suit practically every wet particulate process, delivering real-time measurement, monitoring and control 24/7.

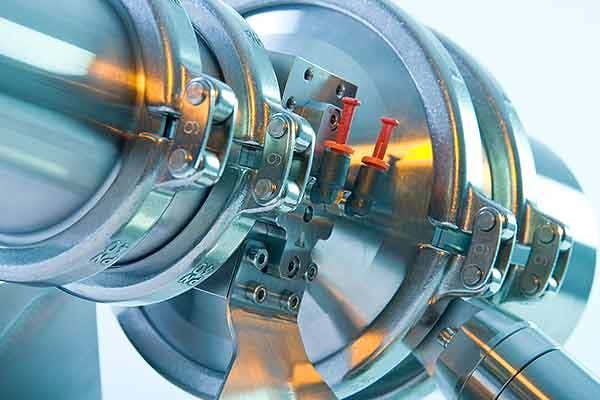

A variable path length particle sizing sensor that offers maximum flexibility for wet applications, to deliver reliable, continuous monitoring 24/7 under operating conditions that include high temperature or pressure, high or variable solids loadings. Suitable for measuring particles from 0.1 to 2500µm in emulsions, suspensions and slurries.

The rugged PSI 500 has integrated, automated concentration control and measures complete particle size distributions at a rate of one per minute. Suitable for measuring particles in the size range 0.1 to 2500µm it was developed with Metso:Outotec, one of the world’s leading suppliers of technology to the minerals and mining sector.

Protect your investment and ensure optimized performance at all times with Malvern Panalytical's service plans.

When you purchase a Malvern Panalytical product we understand that this is just the first stage of a working relationship that will last for the lifetime of the instrument. Depending on your needs, Malvern Panalytical will provide the support for your business.

For laboratories where maximizing instrument up-time is critical to its daily performance. Our highest level of response and the 'all inclusive' price plan takes care of those unexpected repair bills should the unfortunate occur.

Enhance your laboratory productivity by maintaining instrument efficiency. Still receive that priority response, combined with specialist technical and software support, we'll keep your instrument performance on track to deliver.

For laboratories looking to optimize instrument performance, regular preventative maintenance is essential.

| Platinum Plan | Gold Plan | Bronze Visit | |

|---|---|---|---|

| Annual PM/PV Test | yes | yes | no |

| Telephone / Email Support | yes | yes | no |

| Priority Response | yes | yes | no |

| Emergency Breakdown visits* | yes | yes | no |

| Parts Included | yes | no | no |

| Technical & Software Support | yes | yes | yes |

| IQ/OQ (Pharma)*** | yes | yes | yes |

*including labour & travel costs ***available at an additional cost