Overview

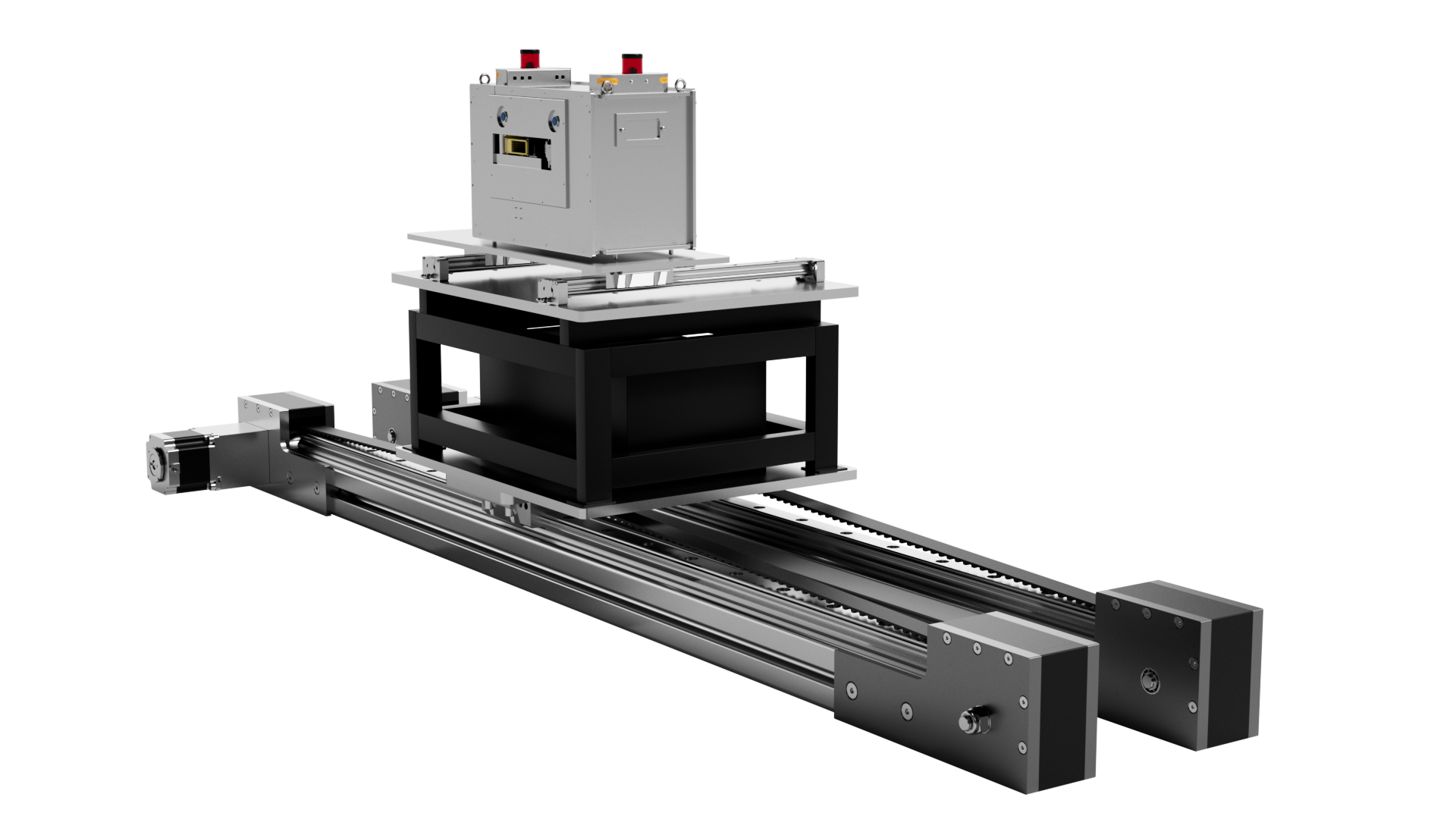

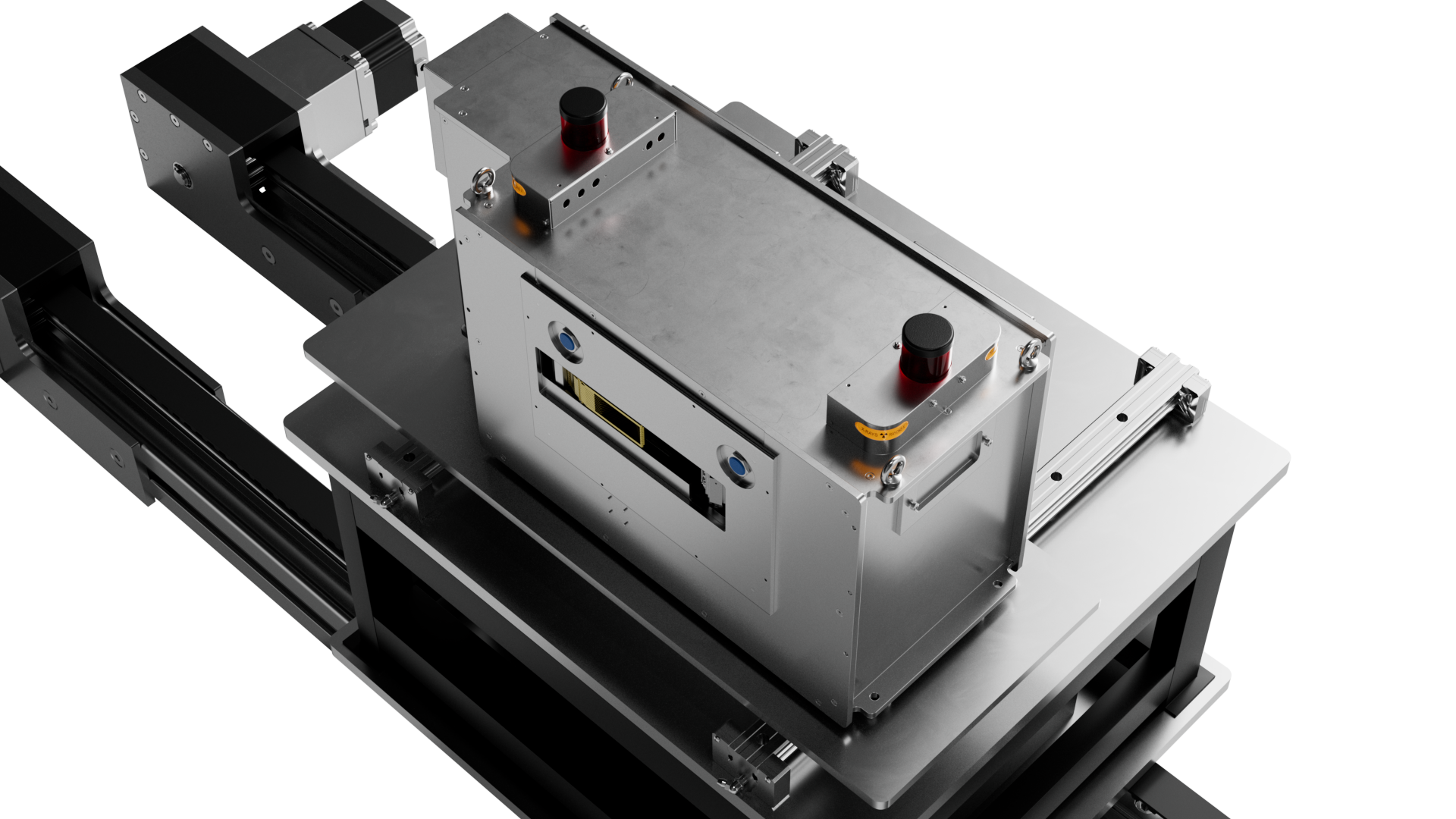

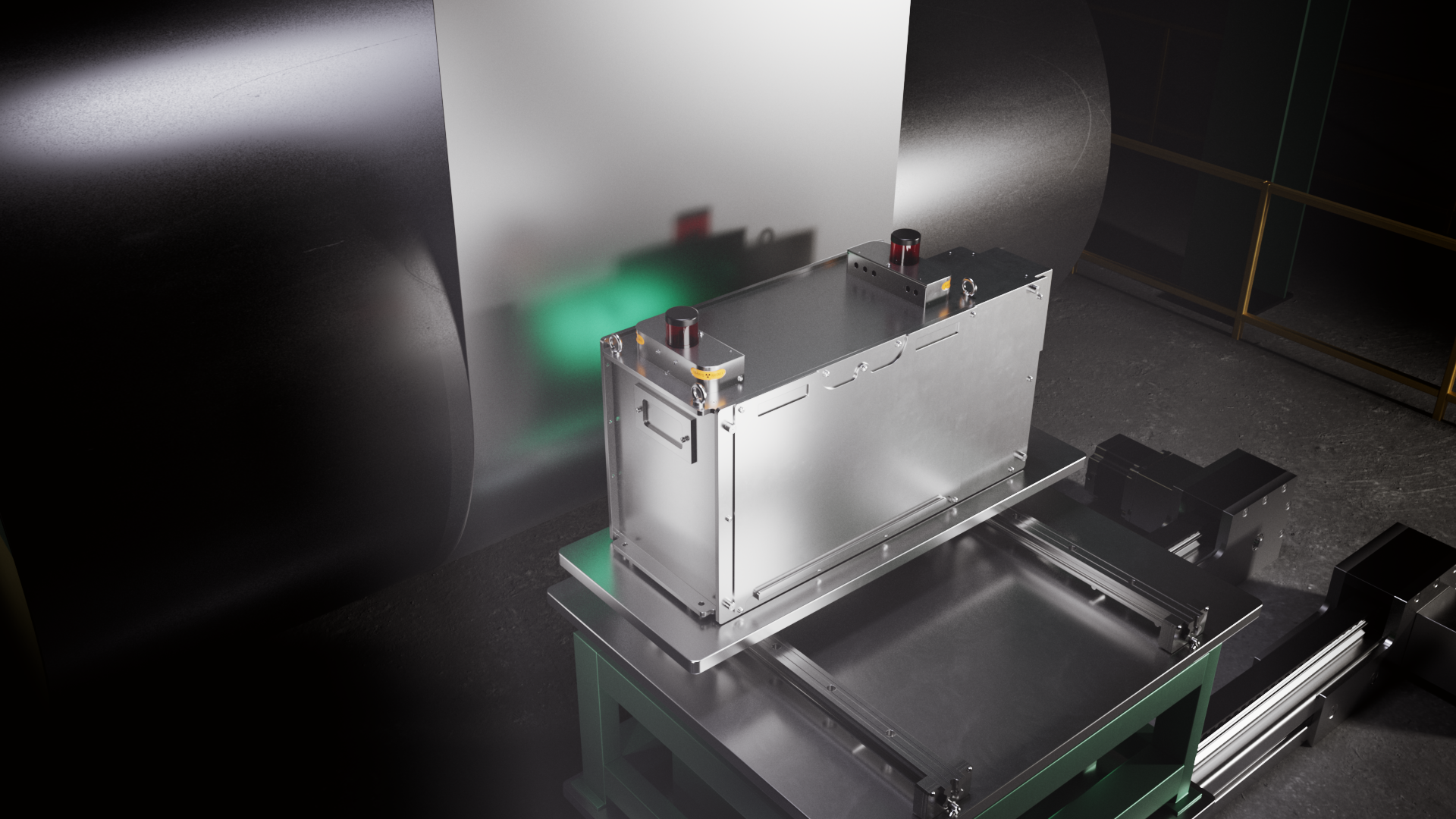

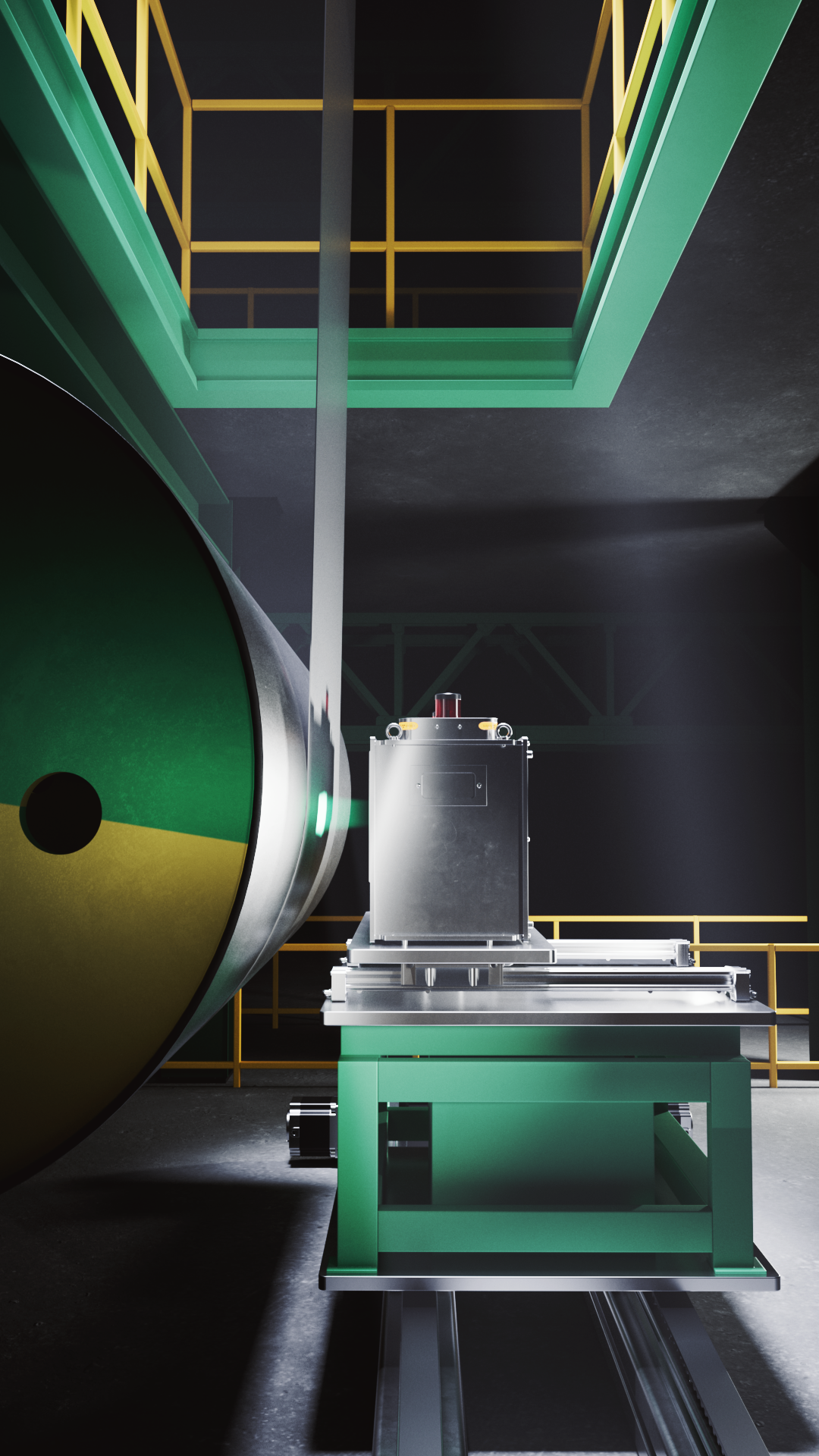

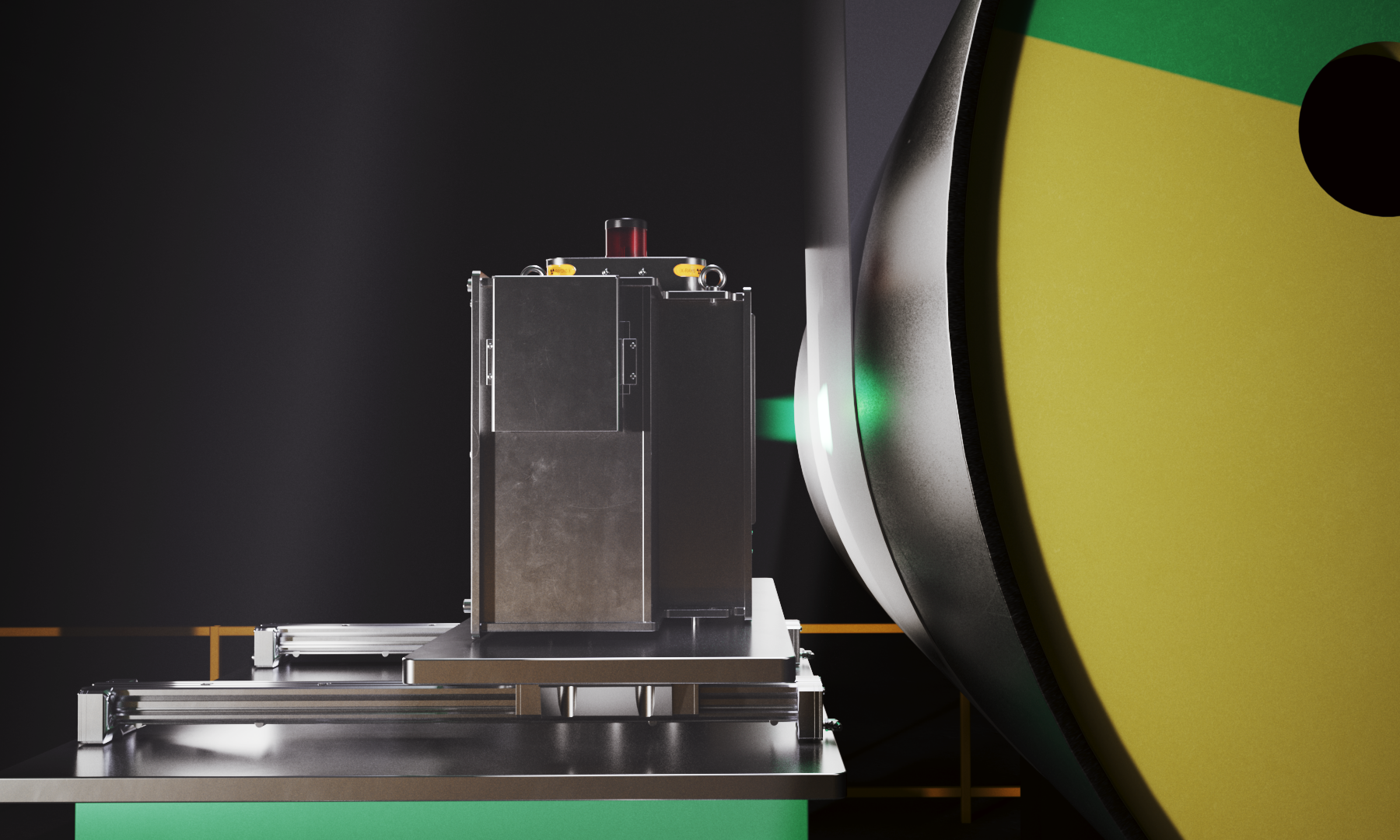

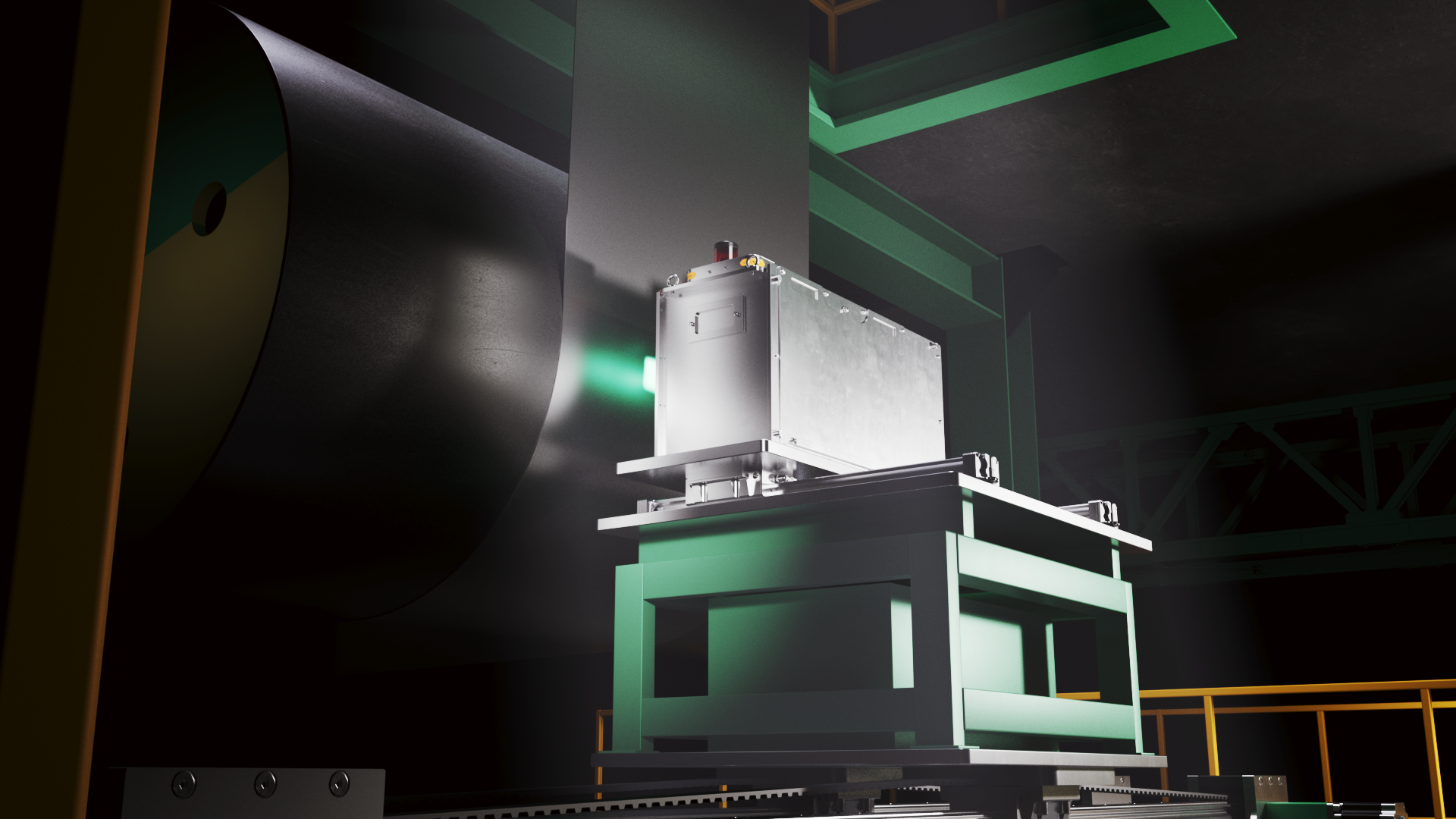

Crystallographic data from XRD are ideal for analyzing galvannealed steel – but with Malvern Panalytical on-line XRD there’s no need to wait eight hours for the results of an off-line sample. Our game-changing on-line solution means you can monitor critical process parameters in real time, from crystallographic phase composition to layer thickness. Plus, this instrument provides close-to-lab-quality sensor measurements, so you know you’re getting results you can rely on.

All this enables you to more quickly identify and resolve any problems in your steel galvannealing, gaining important time, energy, and materials savings: great news not only for your site’s cost efficiency but also for the environment.

Features and Benefits

- Reduced process errors and waste

Monitoring your galvannealing process improves precision and reduces the need to re-melt your steel coil

- Maximized uptime

On-line XRD provides on-line results in real time – enabling you to keep production running and allowing lab staff to focus on other tasks

- Improved cost efficiency

Reduce your raw material and energy usage, maximize productivity by improving your uptime, and sell your steel for the highest possible price

- Lower environmental impact

With On-line XRD, you can avoid the wasted energy and raw materials that come with re-melting your steel coil, helping you meet the growing demand to reduce the environmental impact of your operations

- Quick and easy set-up

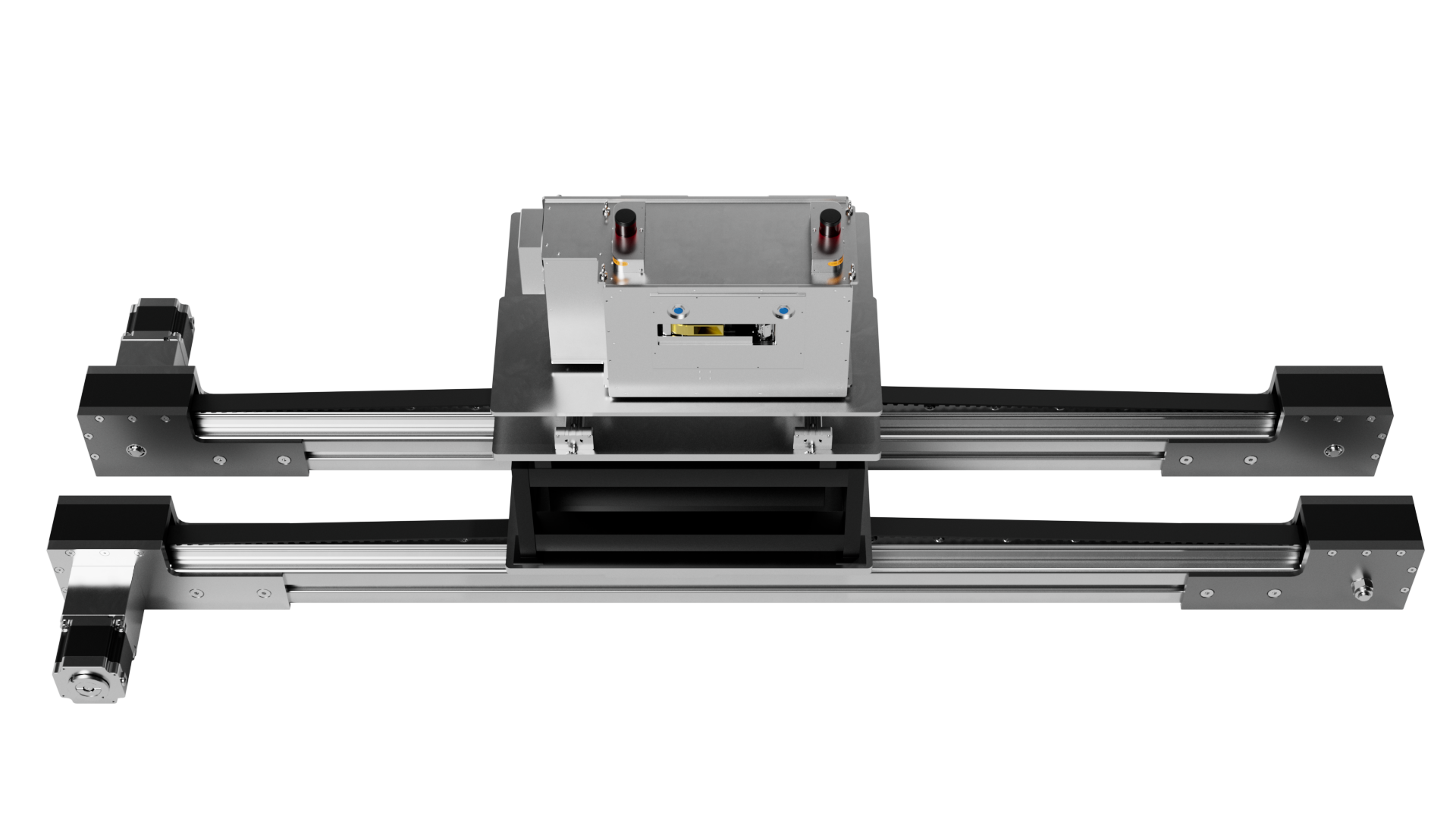

On-line XRD can be installed in a single day, for example during planned maintenance, getting you up and running with no disruption to your production process

Layer thickness and phase composition

- Online/Inline, real-time, fully automated XRD analysis of galvannealed steel during the production process.

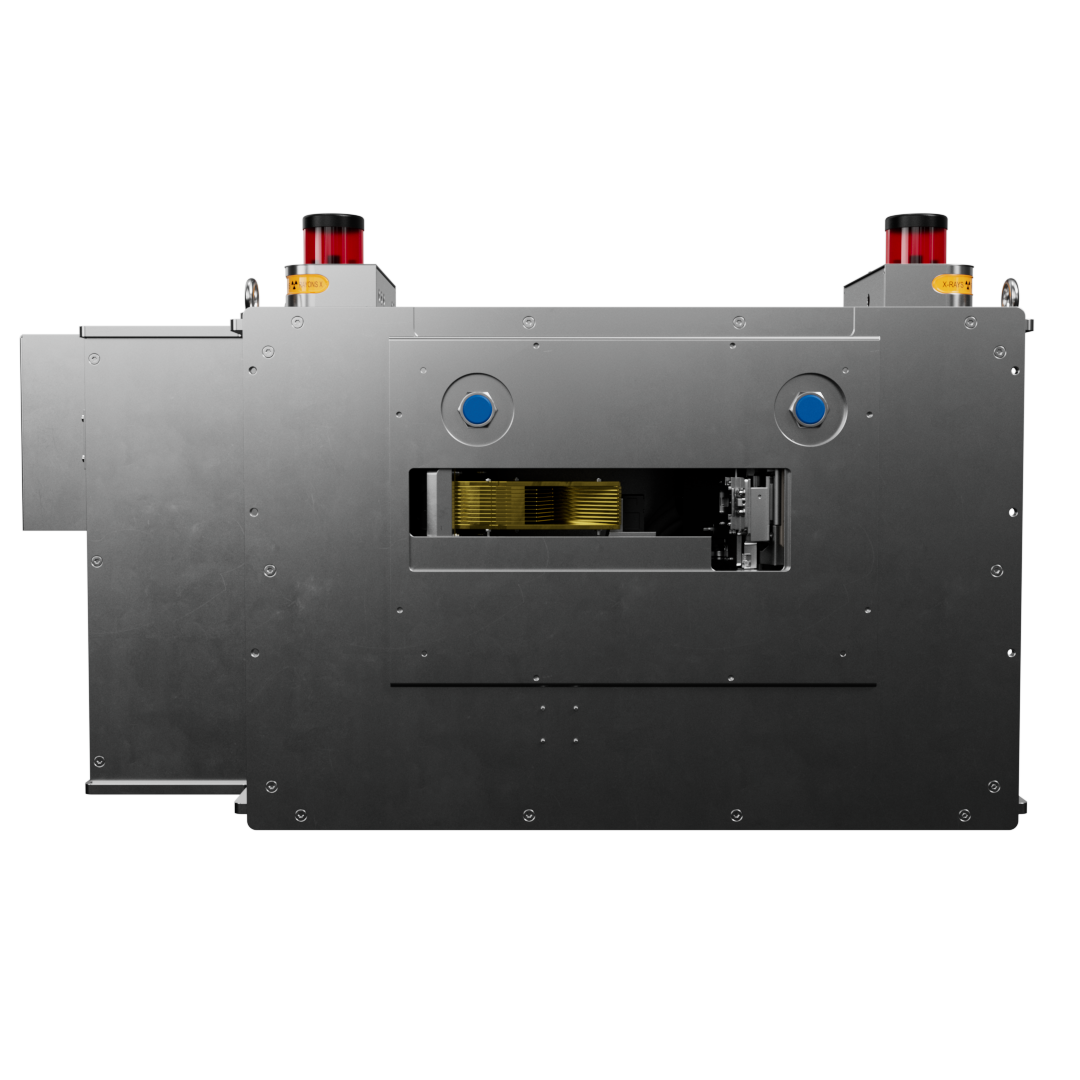

- The new thickness analysis algorithm in HighScore 5.3 determines the individual thickness of all phases (zeta, delta, gamma1, gamma) within the galvannealed Fe/Zn layer.

- Fully implemented system monitoring and intensity calibration

Specification

| Sample handling | |

|---|---|

| Sample loading | External sample loading

Internal sample loading |

| Types of samples | Circular samples ø16 mm, ø32 mm, and ø50 mm

Rectangular samples 40 x 70 mm and 50 x 245 mm |

| Sample changing | Manual (external loading) 3 position sample changers for circular samples up to ø32 mm (internal loading)

Up to 3 reference sample positions Integrated webcam |

| X-ray generation | |

| Anode materials | Empyrean type, Cu, Co and Cr |

| Focus size | Focus size 0.4 mm x 12 mm (LFF) |

| Construction of X-ray tube | Construction of X-ray tube Ceramic insulation |

| Generator settings | Cu-radiation: 45 kV and 40 mA @ 1800 W

Co-radiation: 40 kV and 40 mA @ 1600 W Cr-radiation: 30 kV and 55 mA @ 1650 W |

| Tube housing | The tube housing is Pb-free. Patented design with CRISP* (corrosion-resistant incident smart beam path) technology.

CRISP technology prevents corrosion in the incident beam path caused by X-ray-induced ionized air. Patent no. US 8437451 B2 |

| General specification | |

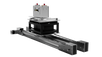

| Dimensions (H x W x D) | 695 x 1015 x 468 mm |

| Weight | +/- 200 kg |

| X-ray safety | X-safe controller PCA: less than 1 microSv/hr at 10cm distance from the outside surface of the box |

| Safety standards | CE |

| Dust protection | Box over pressured with compressed filtered air |

| External cooling water | Yes |

| Compressed air supply | 4-6 bar |

| Power supply | 230V 1ph 32A |

| System alignment | Delivered factory aligned |

| Computer | External |

| Operation | External via customized UI |

| Interfaces | LAN |

Support

Services

Solutions to maximize the return on your investment

To assure that your instrument remains in top condition and performs on the highest level, Malvern Panalytical offers a wide range of services. Our expertise and support services assure an optimal functioning of your instrument.

Support

Service for a lifetime

- Phone and remote support

- Preventive maintenance and checkups

- Flexible Customer Care Agreements

- Performance certificates

- Hardware and software upgrades

- Local and global support

Expertise

Adding value to your processes

- Sample preparation development/optimization

- Analytical methodologies

- Turnkey solutions for XRD

- Operations via IQ/OQ/PQ, quality assurance (GLP, ISO17025) or round robins/inter laboratory studies

- Automation of lab processes

- Consultancy services

Training and education

- Training on-site or at our competence centers

- Broad range of basic and advanced courses on products, applications and software

Analytical services and calibration materials

- Expert (XRF) analyses services

- Oxides and trace analysis

- Customized calibration materials