Overview

The Aero S is a completely new dry powder disperser developed using state-of-the-art powder dispersion understanding. Modular in design, it is easily configured for different applications, delivering efficient sample dispersion for both robust and fragile materials.

- Standard disperser suitable for both cohesive and fragile particle measurements.

- Impaction systems available for robust material dispersion.

- Precise dispersion pressure control, to ±0.1 bar delivers outstanding reproducibility.

- Range of sample feed trays and hoppers enable measurement of different sample volumes.

- Enclosed cell delivers bias-free measurements whilst minimizing user exposure to the sample.

- Full software control of all measurement functions, including sample feed and dispersion.

- Ceramic dispersers available for abrasive materials.

How it works

Dry measurement of particle size is fast and removes the need for liquid dispersants. It is the best method for many dry powders, and is especially important when particle size is influenced by hydration. The Aero S disperses dry samples by accelerating particles through a venturi using compressed air. The particles are then pulled through the Mastersizer’s measurement cell using a vacuum source.

Dispersion efficiency is controlled by three variables: air pressure, sample feed rate and disperser geometry.

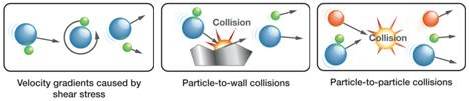

Mechanisms of dry powder dispersion: Representative measurement relies on providing sufficient energy to break up agglomerates without causing primary particle damage. Dry powder dispersers accelerate particles in an airstream to achieve this.

With dry powder dispersion there is always the possibility of particle damage, because of the high velocity at which the particles pass through the disperser system. The unique design of the Aero S minimizes this problem by avoiding impaction surfaces. Dispersion is achieved through the application of significant shear, rather than by impacting particles on a surface. The result is gentle but highly efficient dispersion, which can be successfully applied to even relatively friable materials. Optional impaction systems are available for strongly agglomerated samples with tough primary particles. The air pressure drop across the venturi is manipulated to achieve complete sample dispersion and can be controlled to within +/-0.1 bar.

Sample feed rate through the Aero S is closely controlled using a vibrating feeder, which maintains a suitable sample concentration for measurement. It is fitted with an interchangeable sample tray that can be configured to ensure the measurement of enough material to quantify the entire size distribution reproducibly.

Thanks to its high data acquisition rate, the Mastersizer 3000 samples the dispersed material very efficiently, even though material passes through the measurement cell quickly. This increases the measurement robustness, and accelerates analysis.

In combination, these features deliver reliable, reproducible dispersion for the very widest range of dry samples.

Specification

| Particle size | 0.1 - 3500 µm † |

|---|---|

| Dispersion pressure range | 0 - 4 bar |

| Pressure setting precision | +/- 0.1 bar |

| Pressure setting accuracy | +/- 0.03 bar |

| Feed rate range | 0 - 58ms-2 (expressed as 0-100%) |

| Feed rate precision | 2% FS |

| Materials in contact with the dispersant, additives and sample | 316 stainless. 410 hardened stainless. Borosilicate glass. EPDM. PTFE. Polyurethane. Carbon filled acetal. Aluminum. Neoprene. |

| Maximum particle size | 3500 µm † |

| Minimum time between measurements | Less than 60 seconds † |

| Dimensions (W, D, H) | 180mm x 260mm x 380mm |

| Weight | 10.5kg |

| Power | Supplied via the optical unit. |

| † | Sample dependent |