Overview

The Aero M is designed to enable particle size and size distributions to be measured for dry powder samples. Its modular design aids enables it to be configured to achieve robust particle size measurements in different applications and also ensures it is easy to maintain during routine use.

- Fast, reproducible measurements achieved without the need for liquid dispersants.

- Large sample masses can be measured, ensuring good sampling is achieved.

- Measurement reproducibility is maintained through software verification of the sample dispersion settings during measurements.

- Can be configured for different applications through the purchase of additional sample trays and powder hoppers.

- Abrasive samples can be measured through the use of ceramic venturi dispersers.

How it works

The use of dry powder dispersion of particle size and size distribution measurements is advantageous when measuring bulk materials, as a large mass of powder can be measured. This helps with the sampling of materials which are polydisperse. In addition, dry powder dispersion avoids the need for liquid dispersants, reducing the cost of measurement and increasing sample through-put.

The Aero M disperses dry samples by accelerating particles through a venturi using compressed air. The particles are then pulled through the Mastersizer 3000E’s measurement cell using a vacuum source. Dispersion efficiency is controlled by the applied air pressure and the sample feed rate.

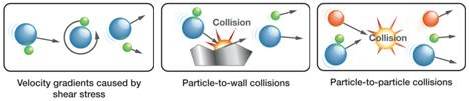

Mechanisms of dry powder dispersion

Dry powder dispersion is achieved through the shearing of agglomerates as they accelerate through the venturi disperser. Particle-particle collisions and particle-wall collisions also help with the dispersion of strongly agglomerated. The energy associated with each of these dispersion mechanisms is controlled by setting the air pressure drop across the venturi. This ensures dispersion to the primary, dispersed particle size prior to measurement using the Mastersizer 3000E optics unit.

Sample feed rate through the Aero M is closely controlled using a vibrating feeder, which maintains a suitable sample concentration for measurement. This ensures that reproducible, rapid measurements can be made.

Specification

| Particle size | 0.1 - 1000 µm † |

|---|---|

| Dispersion pressure range | 0 - 4 bar |

| Pressure setting precision | +/- 0.1 bar |

| Pressure setting accuracy | +/- 0.03 bar |

| Feed rate range | 0 - 58ms-2 (expressed as 0-100%) |

| Feed rate precision | 2% FS |

| Materials in contact with sample | 316 stainless. 410 hardened stainless. Borosilicate glass. EPDM. PTFE. Polyurethane. Carbon filled acetal. Aluminum. Neoprene. |

| Maximum particle size | 1000 µm † |

| Minimum time between measurements | Less than 60 seconds † |

| Dimensions (W, D, H) | 180mm x 260mm x 380mm |

| Weight | 10.5kg |

| Power | Supplied via the optical unit. |

| † | Sample dependent. Relates to the use of the unit with the Mastersizer 3000E, which also has a upper size limit of 1000 µm. |