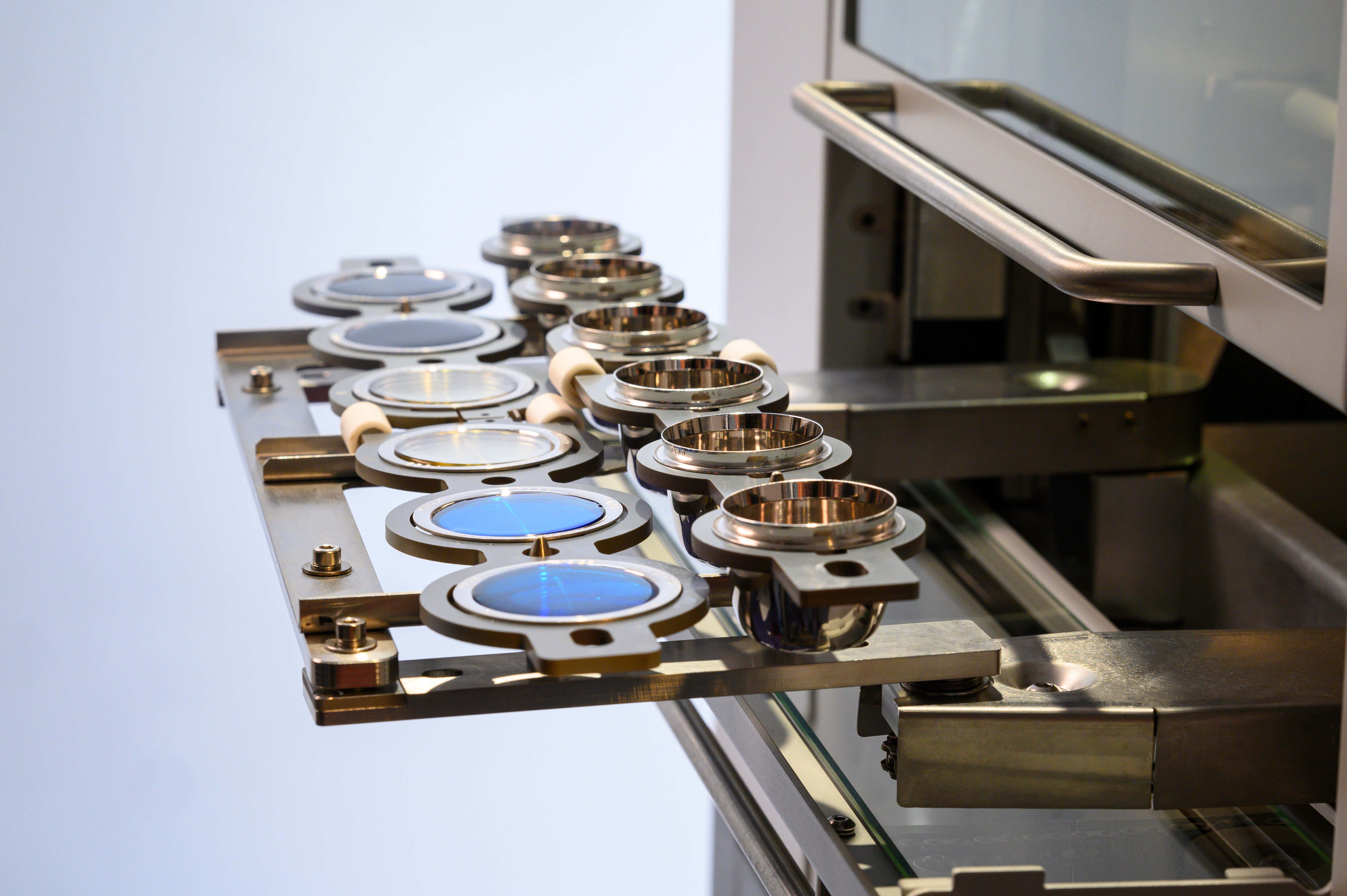

Tray loader

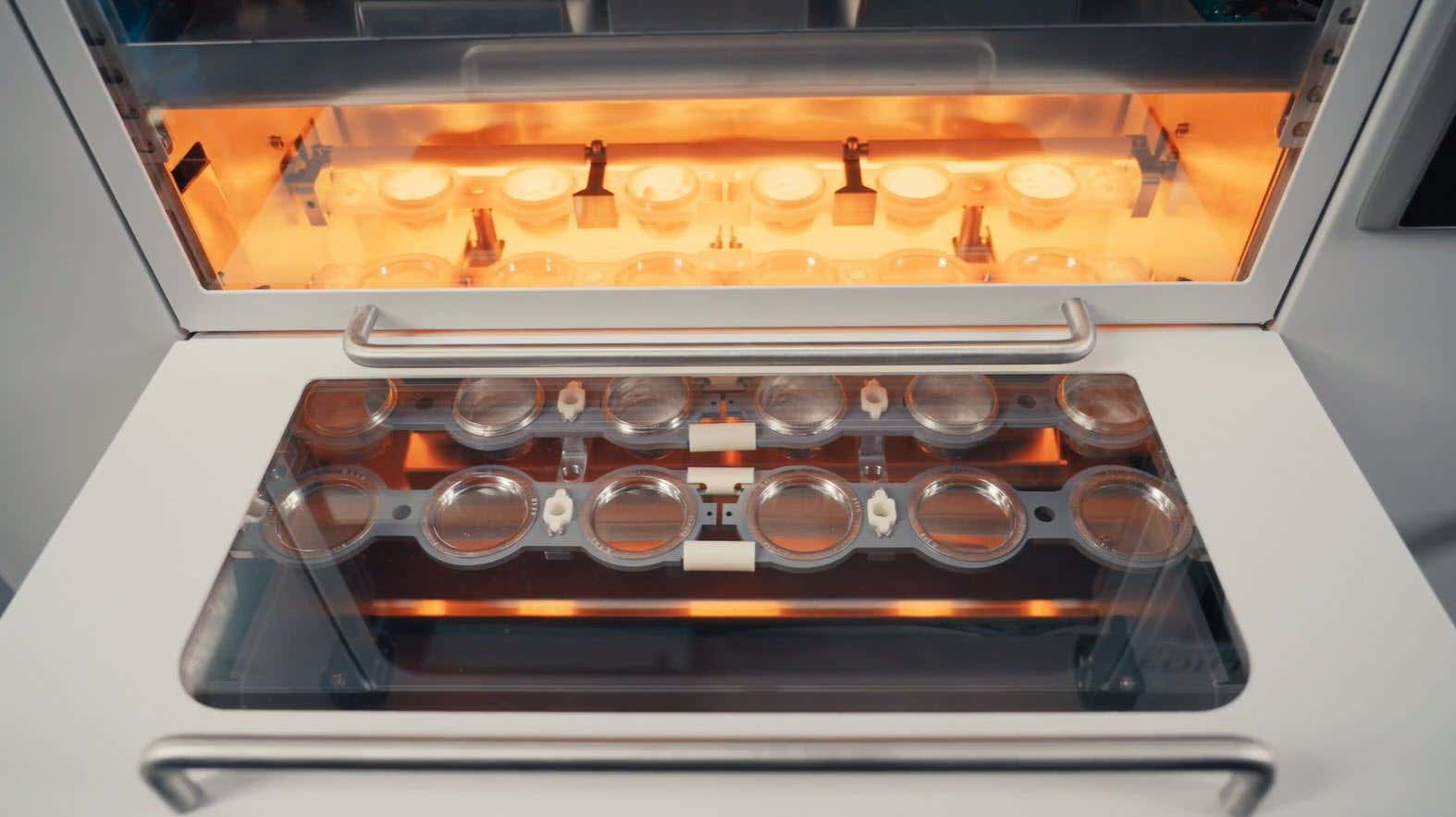

Load up to 12 samples at a time and enable a fusion cycle to start without operator presence. No time wasted in the heating chamber, up to 25% productivity increase and lower operation time.

Developed to deliver the highest levels of robustness, unmatched productivity, and superior-quality results, FORJ™, a Claisse technology, is a game changer for sample prep by fusion. Whether your analysis is based on X-ray fluorescence (XRF), inductively coupled plasma (ICP), or atomic absorption (AA), FORJ is an essential link in your analytical chain.

The costs of downtime and replacement parts are the last thing you want in the lab. Designed for less thermal stress and reduced risk of contamination, FORJ minimizes the need for maintenance, ensuring greater efficiency and higher productivity.

Analytical chains depend on the repeatability of results – and for that, high-quality sample preparation is key. FORJ enables consistent heating between fusion positions, homogeneous melt, and contamination-free heating for superior analytical results.

In sample prep, high-throughput fusion instruments are fundamental. Thanks to its tray loader option, FORJ is the fastest on the market – boosting productivity by up to 25% with the same compact footprint.

New fusion instruments shouldn’t be a source of frustration. Suitable for full-lab integration, FORJ is easy to install and provides a safe and user-friendly interface, so you can quickly get up and running.

At Malvern Panalytical, we’re experts in elemental analysis. Offering services ranging from on-site or remote technical and engineering support to useful training and practical advice, our network is here to give you the support you need.

Load up to 12 samples at a time and enable a fusion cycle to start without operator presence. No time wasted in the heating chamber, up to 25% productivity increase and lower operation time.

A non-wetting agent (NWA) pill injector function that contributes to homogeneous melting and helps avoid disk breakage to ensure on-time delivery and optimize results.

| Productivity | |

|---|---|

| 6 fusion positions | Pre-loading of 6 additional samples with tray loader option |

| Robustness and operation | |

| Platinum ware detection by camera | |

| Ergonomic manipulation | |

| Integrated supercapacitor | |

| Power-saving: programmable pre-heat and shut-off timer | |

| Light tower | |

| Usable with WROXI-CRM | |

| Fusion success enhancers | |

| Pause and inspection function | |

| Fast heat drop | |

| Non-wetting agent pill injector | |

| Furnace refractory monitoring | |

| Performant pre-set programs with full method descriptions for the most common applications | |

| Adaptable temperature, step duration, agitation speed, cooling airflow, magnetic agitation, and pouring approach | |

| Multiple program views: remaining time, temperature vs time graph, and fusion step details | |

| Modes | |

| Disks (XRF) | Crucibles and molds, Crucimolds |

| Borate solution (ICP/AA) | In beaker with diluted acid |

| Peroxide fusion (ICP/AA) | Low-volume crucibles: 25, High-volume crucibles: 50 ml |

| Thermal treatment | Heat sample in crucible at required temperature and time |

| Connectivity and software | |

| Fusion success monitoring | |

| Sample tracking | |

| Remote control | |

| Ethernet connection and USB ports | |

| Safety | |

| Cold-to-cold operation | |

| CSA-CA, CSA-US, CE, RoHS, UKCA | |

| Coated PCB for high corrosion resistance | |

| Dimensions and weight of the basic configuration | |

| Height | 68.2 cm (26.8 in) |

| Width | 100.5 cm (39.6 in) |

| Depth | 73.0 cm (28.7 in) |

| Weight | 127 kg (280 lb) |

| Electrical requirements | |

| 30 A, 5500 VA | |

| Canada and USA | 208-240 V, 60 Hz |

| Other countries | 200-240 V, 50/60 Hz |

| Other | |

| Maximum operating temperature | Periodic: 1250° C, Steady: 1200° C |

| Fume extraction | Exhaust adapter or installation under a hood |

To assure that your instrument remains in top condition and performs on the highest level, Malvern Panalytical offers a wide range of services. Our expertise and support services assure an optimal functioning of your instrument.

Adding value to your processes

Claisse does not only provide high quality and reliable instruments, it also takes the operator’s safety and the customers’ entire satisfaction into consideration.

Maria Petrov — BASF

The world's fastest, safest and most accurate fusion instrument. A game changer for sample preparation.