Features

-

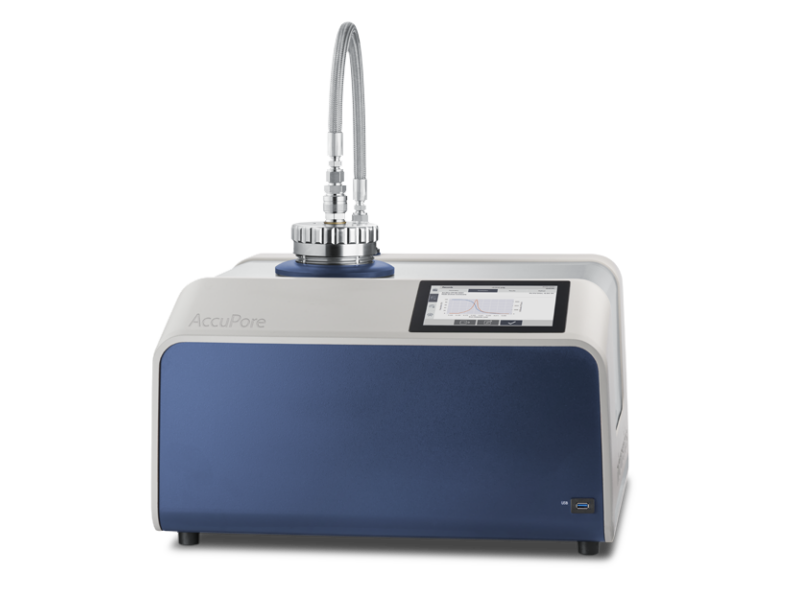

Flexible easy-to-use sample chamber for simple sample loading, including samples from 13 mm to 47 mm diameter

-

Intuitive Breeze interface makes it easy to measure samples and review results with or without a PC

-

Convenient USB access for data transfer or peripheral device integration - with even more ports at the back of the instrument

-

High-speed control, collection, and data processing provides the most accurate pressure control, highest curve resolution, and most detailed pore size distribution by processing measurements at up to 20 Hz

-

MIC Net empowers your lab to operate as one by synchronizing results and methods across AccuPore instruments. Laboratory network connection provides simple data retrieval and LIMS integration

-

Auto-switching gas supply reduces cost of operation by using low pressure compressed air when suitable, allowing high pressure bottled gas tanks to last longer

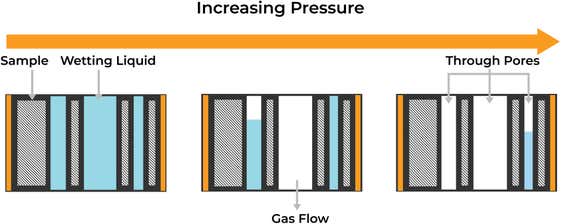

How capillary flow porometry works

Capillary Flow Porometry — also known as Gas Liquid Porometry — is a fast, reliable method to determine the size and relative abundance of through-pores in sheets and membranes.

This pressure-based technique measures the minimum diameter of a pore, averaging over a significant test area, without the need for model-fitting or image processing. Measurements are fast, sample preparation takes less than 30 seconds, and no mercury is involved.

- Sample preparation: the sample is wetted with a special fluid that fills every pore.

- Wet curve: gas pressure is applied to force the wetting fluid from the pores. Larger pores open at lower pressure. Increasing pressure opens more, smaller pores, increasing the gas flow rate through the sample.

- Dry curve: After all pores are opened and all the wetting fluid has been expelled from the sample, flow across the un-wetted dry film is measured.

Key measurements

- Bubble Point, Largest Pore: The lowest pressure at which flow occurs.

- Mean Flow Pore: Intersection of the wet curve with the dry curve divided by two — the half-dry curve.

- Smallest Pore: Intersection of the wet curve with the dry curve.

- Pore Size Distribution: A continuous distribution of the differential and cumulative pore size reveals the overall structure of pores in a membrane.

Pressure ramp and step capability

The SmartFlow system in the Micromeritics AccuPore provides precision control for porosimetry in either pressure ramp or step modes. The option to perform measurements in either mode ensures the correct measurement is available from routine qualification to detailed characterization.

Increasing pressure at a steady rate shortens measurement time, provides a highly repeatable measurement, and produces data points tightly spaced in pressure.

Routine operation produces high-resolution, highly repeatable data, in a short time.

Pausing at each pressure for equilibration allows all pores of a given diameter to fully empty before moving to the next pressure, regardless of pore length or tortuosity.

This offers the highest possible resolution and absolute pore size accuracy, especially for complex pores and thick sheets.

Detailed pore distribution without curve fitting

Highly detailed pore size distributions are enabled due to high-resolution, low-noise pressure-flow curves in the AccuPore. The distributions reflect physical pore architecture without curve fitting or post-processing requirements.

![[Micromeritics - AccuPore - Pore distribution graphs.png] Micromeritics - AccuPore - Pore distribution graphs.png](https://dam.malvernpanalytical.com/a00177c5-2864-4927-be97-b29700da45c4/Micromeritics%20-%20AccuPore%20-%20Pore%20distribution%20graphs_Original%20file.png)

Better measurements with Smartflow

The Micromeritics AccuPore features SmartFlow, an advanced flow control system that guarantees the most precise pressure control, highest sensitivity, and lowest signal noise.

The SmartFlow control system uses high-resolution 24-bit electronics operated at 20 Hz for optimal signal quality and system response.

SmartFlow has eight complementary transducers and controllers, which provide the most responsive and stable performance, even during rapidly changing conditions such as pore opening.

Applications

Optimize the rate of ion transport and physical separation to ensure device safety. Precision sample supports and advanced pressure control enable accurate measurements up to high pressure for small pores and thin membranes.

Predict and ensure size-based selectivity and mass-transfer rate by optimizing the number and size of pores.

Often characterized by a broad distribution of pore sizes due to their production methods. These are common choices for filtration media. In-plane porosity and irregular pore shapes make steady flow determination of bubble point especially important.

Preferred for thermal, physical, and chemical resistance, these materials often have highly porous structures. The three-dimensional porosity of these materials makes it especially important to measurement porosity in the direction of intended flow.