Scientists, researchers, and quality control managers around the world use laser diffraction for particle size analysis. But, to develop truly high-performance products, you often need deeper insights than those provided by laser diffraction alone. In particular, to understand the influences behind packing, flow, and dissolution rate, you need to understand how particle size and shape affect your materials’ behavior.

The Hydro Insight accessory provides these insights by combining Vision Analytical’s dynamic imaging expertise with Malvern Panalaytical’s flow cell and dispersion technology. Sitting alongside our Mastersizer 3000 laser diffraction system, the Hydro Insight provides real-time images of your liquid particle dispersions and individual particles. It provides quantitative data on particle shape as well as a window into your laser diffraction measurement, so you can troubleshoot more easily and develop particle sizing methods more quickly.

If you’re still not convinced, we hope this white paper will outline the benefits of adding the Hydro Insight dynamic imaging accessory to your Mastersizer 3000.

Scientists, researchers, and quality control managers around the world use laser diffraction for particle size analysis. But, to develop truly high-performance products, you often need deeper insights than those provided by laser diffraction alone. In particular, to understand the influences behind packing, flow, and dissolution rate, you need to understand how particle size and shape affect your materials’ behavior.

Figure 1: Hydro Insight

The Hydro Insight accessory provides these insights by combining Vision Analytical’s dynamic imaging expertise with Malvern Panalaytical’s flow cell and dispersion technology. Sitting alongside our Mastersizer 3000 laser diffraction system, the Hydro Insight provides real-time images of your liquid particle dispersions and individual particles. It provides quantitative data on particle shape as well as a window into your laser diffraction measurement, so you can troubleshoot more easily and develop particle sizing methods more quickly.

If you’re still not convinced, we hope this white paper will outline the benefits of adding the Hydro Insight dynamic imaging accessory to your Mastersizer 3000.

Combine shape data from dynamic imaging with particle size distributions from laser diffraction and get a deeper understanding of why your materials behave the way they do.

Laser diffraction is fast becoming the standard particle sizing technique across many industry sectors for several reasons. For example, it is:

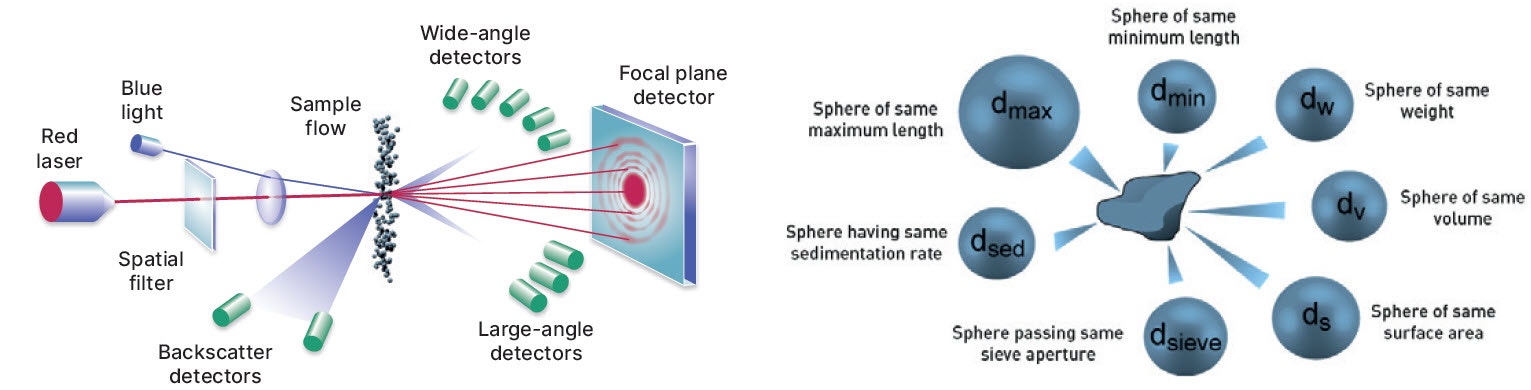

Laser diffraction determines particle size distributions by measuring the angular variation in the intensity of light scattered as a laser beam passes through a dispersed particulate sample. Large particles scatter light at small angles relative to the laser beam and small particles scatter light at large angles. By analyzing the angular scattering intensity data, the size distribution of the particles responsible for creating the scattering pattern can be calculated. And because it is an ensemble technique, large numbers of particles are sampled in each measurement, providing excellent reproducibility.

Figure 2: illustration of a laser diffraction measurement using the Mastersizer 3000 (left) and common sphere equivalent particle size metrics

However, like most particle size distribution techniques, the complex geometries of real-life particles are reduced to a spherical equivalent. The challenge becomes how each technique does that transformation, as they are all slightly different.

Enter the Hydro Insight. This dynamic imaging tool sits alongside the Mastersizer 3000 to give you real-time images of your particles at the same time as your laser diffraction measurements. And it can do this for individual particles or the whole dispersion. This information will help rationalize the results from laser diffraction and other techniques.

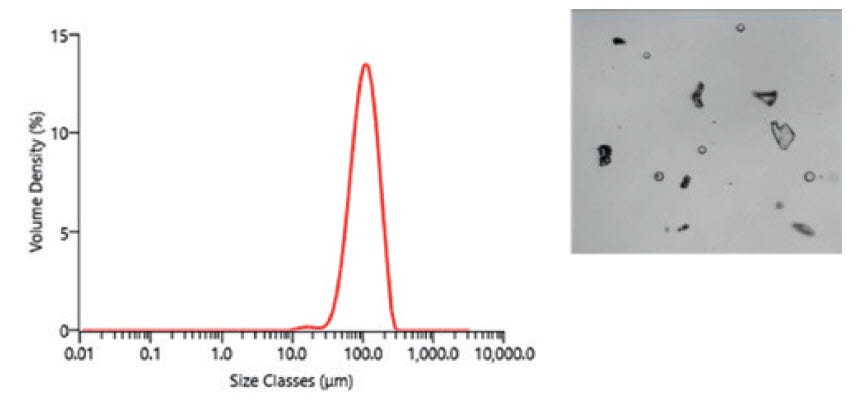

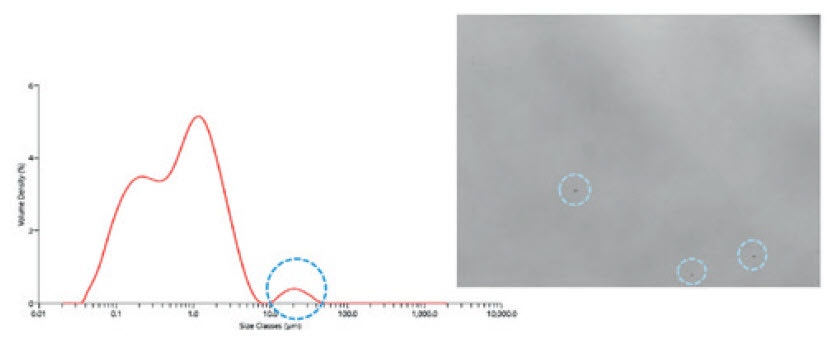

Figure 3: Particle size distribution measured on the Mastersizer 3000 and corresponding particle dispersion images from Hydro Insight.

Furthermore, the Hydro Insight can use these insights to give you quantitative data on the shape of your particles. Alongside the data on particle size distribution from the laser diffraction measurements, there are 32 size- and shape-related metrics such as circularity, ellipticity, opacity, mean diameter, and aspect ratio. This allows you to understand how the combination of particle size and shape affects your materials, so you can get to the bottom of why your materials behave the way they do. This is important because differences in particle size and shape can impact:

The high-resolution imaging and wide dynamic range of laser diffraction provide a comprehensive overview of your materials and a better understanding of the techniques used to measure them.

See your dispersion as you develop your laser diffraction methods – allowing you to save time for other projects.

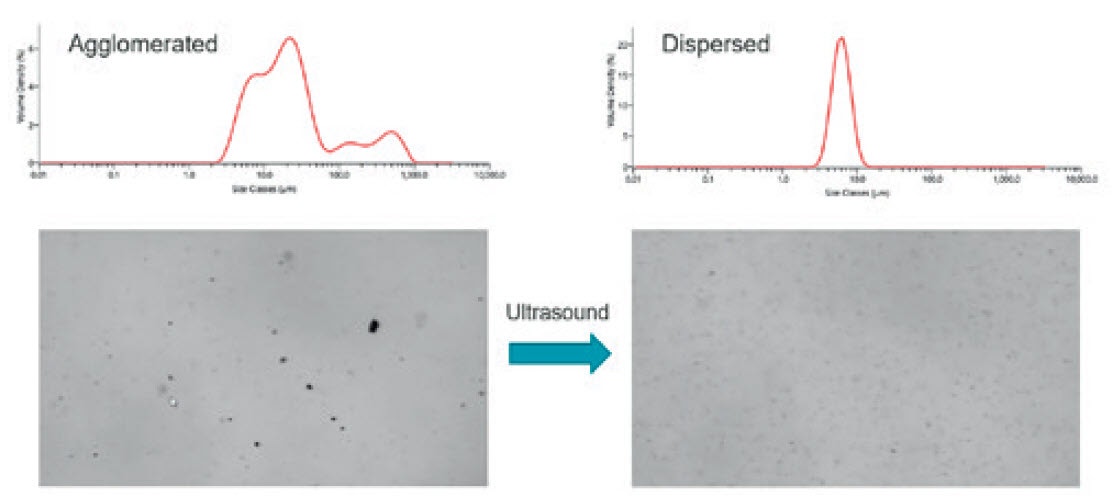

Achieving the optimum dispersion for your laser diffraction measurement is fundamentally important. Otherwise, you’re not actually sure whether you’re measuring primary particles or agglomerates. Ideally, you’re looking for a stable and reproducible state of dispersion that can be achieved by several means in the liquid state such as surfactants, mechanical stirring, or the application of ultrasound. This is often a trial-and-error approach that involves varying the concentration/type of dispersant or the amount of mechanical agitation needed to get a stable size result. Orthogonal techniques such as manual microscopy are also commonly employed to prove that the correct state of dispersion and/or optical properties have been used to produce the laser diffraction result.

Figure 4: Changes in particle size distribution and corresponding Hydro Insight images as agglomerates are dispersed with ultrasound

The Hydro Insight offers real value as it allows you to visualize your particle dispersion in real time. This means you can see whether agglomerates are present in your sample and determine the correct amount of surfactant, stirring, or ultrasound required to disperse them into their primary particles. Furthermore, because the imaging and laser diffraction measurements are performed simultaneously, you can directly correlate and compare your size data with images of your dispersion and individual particles or agglomerates.

Combining the resolution of imaging for larger particles with the wide dynamic range of laser diffraction means you can be completely confident of your materials’ properties.

If you’re creating high-quality materials such as dispersions or powders, a few particles can make a big difference. For example, a few oversized particles can block a nozzle or printhead and cause imperfections in your coating. When manufacturing metal components or batteries, large contaminants can result in serious part or product failures.

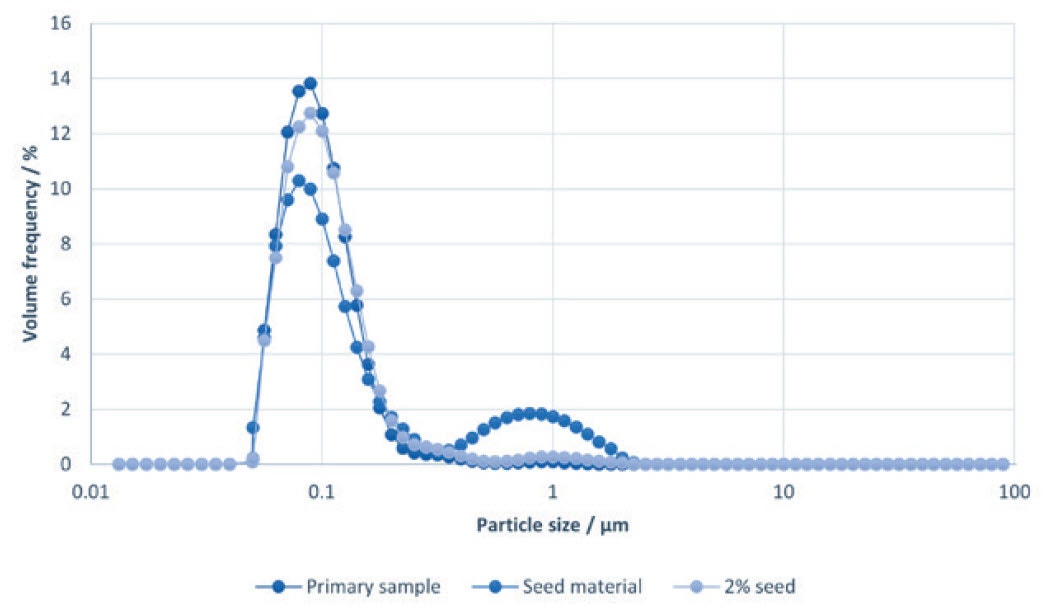

Laser diffraction is a great technique for giving you the big picture with its wide dynamic range, but it is ultimately an ensemble technique. That means the result is based on a statistical representation of the entire sample, as opposed to individual particles. So if your sample contains very small amounts (1-1000 ppm) of large particles in a mixture of smaller particles, laser diffraction will struggle to detect them.

Unlike laser diffraction, the Hydro Insight images individual particles and provides a number-based particle size distribution, so is sensitive to even small numbers of oversized particles. And because it provides individual images for each particle, you can even see what those particles look like. Often, it’s not just oversized particles that are problematic but anomalous particles or contaminants that are irregular in shape. As Hydro Insight provides shape information such as circularity, ellipticity, and aspect ratio, you can identify particle morphologies that differ from the main mode. Therefore, adding the Hydro Insight to your Mastersizer 3000 gives you the best of both worlds – the enhanced resolution of dynamic imaging with the dynamic range of laser diffraction – so the quality of your powdered materials is completely covered.

Figure 5: Laser diffraction can detect a small amount of oversized particle at approx. 1%, but it is much less sensitive at lower concentrations

Use the particle images to troubleshoot particle size results that aren’t what you expect.

Laser diffraction is a simple, fast, and reproducible technique if samples are prepared properly and measured appropriately. But things don’t always go to plan. You may have developed a method that has been shown to give accurate and consistent results but then get an unexpected peak in your distribution.

Does this mean the batch of material you’re testing is ‘out of spec’, or is it just a measurement artifact? Extra peaks in your distribution tend to appear at the coarser end of the spectrum and can be caused by agglomerates, bubbles, or real larger particles. Since particle size distributions produced by laser diffraction are volume-weighted, even a small number of large bubbles or contaminants may show up in your result. Often, the only way to find out the cause is to use an orthogonal off-line technique such as manual microscopy.

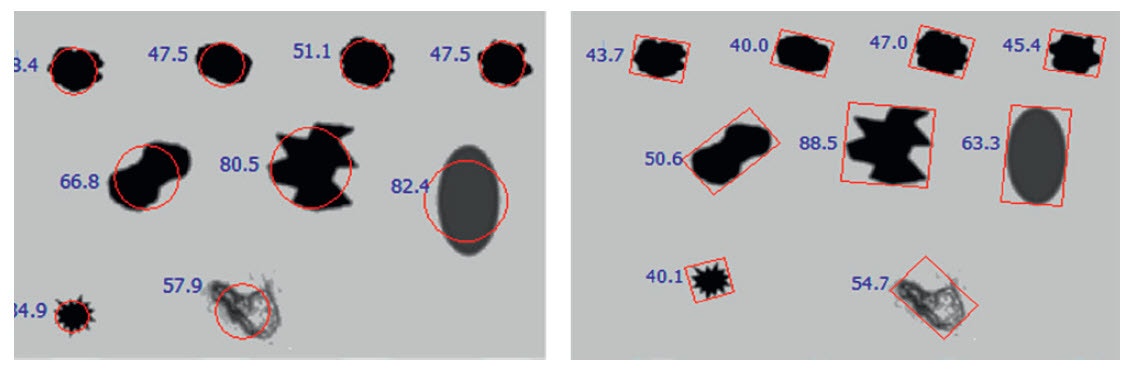

Figure 6: Dispersion and individual particle images from the Hydro Insight will show you what’s behind that extra peak in the particle size distribution

Adding the Hydro Insight to your laser diffraction workflow can speed up the troubleshooting process and is much less laborious than manual microscopy. With the Hydro Insight’s particle images of your dispersion and individual particles, you can save yourself valuable time and effort by easily determining whether out-of-spec particle size results are caused by oversized particles, agglomerates, bubbles, or something else.

Make transferring from sieves to laser diffraction simple with particle width and elongation data.

Sieve analysis is widely used across the manufacturing industry due to its low cost, simplicity, and ability to measure relatively coarse particles up to several centimeters in size. It is also a well-established and trusted technique, with sieve size fractions commonly used to specify and qualify powders, especially coarser fractions.

However, the technique has pronounced drawbacks that make it unsuitable for supporting modern, high-production manufacturing. Firstly, sieving is slow and manually intensive, so replicating measurements is tedious and rarely, if ever, done in practice. Secondly, it offers only low precision and resolution, typically separating a sample into just five to eight fractions. Finally, and crucially, sieving becomes problematic in the sub-100-micron range due to cohesive forces between particles, which often lead to agglomeration. Many of these disadvantages can be overcome by moving to laser diffraction technology, which delivers faster, simpler analysis along with a wider measurement range and better resolution. But transferring your sieve analysis method to laser diffraction is not always trivial, especially when your particles have a degree of irregularity.

This is because sieve analysis classifies particles according to the sieve aperture dimension they pass through, which tends to correspond to the particles’ second largest dimension rather than their primary one. Hence, the result reported is the diameter of a sphere that passes an aperture of a given size. The influence this has on the recorded size distribution is most pronounced for irregular and/or elongated particles. Compare this with laser diffraction, which reports the diameter of a collection of spheres with the same volume as the particles – Circular Equivalent Diameter (CED). Therefore, for elongated particles, laser diffraction reports a larger size compared with sieving, which reports the smallest dimension for an elongated particle.

Adding the Hydro Insight dynamic imaging system to your Mastersizer can help bridge this gap since it can report several different size parameters for irregular particles that may correlate better with sieve analysis. These include:

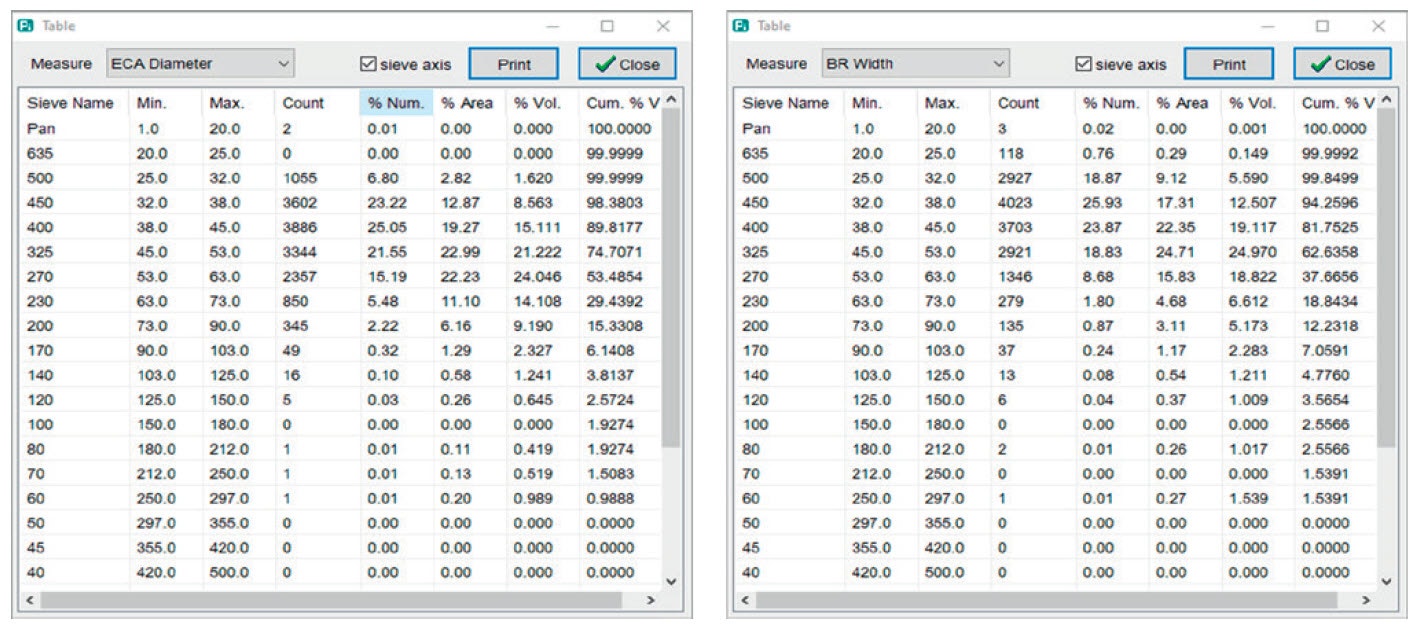

Figure 7: Using Circular Equivalent Diameter (left) and Bounding Rectangle Width (right) to estimate the dimensions of irregular particles

BR Width is the most employed parameter for achieving accurate sieve correlation with irregular particles, but Feret Width or Fiber Width can also be used.

Furthermore, the Hydro Insight software includes a ‘Sieve Mesh Direct Correlation’ algorithm that automatically assigns data to a given sieve fraction or Pan Number based on the chosen metric, as shown in Figure 8.

Figure 8 Sieve correlated results for a sample of irregular particles using Circular Equivalent Diameter (left) and Bounding Rectangle Width (right).

In short, the Hydro Insight complements your laser diffraction measurements in multiple ways, including real-time images of individual and dispersed particles, number-based particle size distributions, and multiple size parameters for irregular particles. Thanks to these features, this accessory enables you to get a comprehensive overview of your materials, troubleshoot more easily, and accelerate your method transfers – ultimately ensuring the best possible material quality. In this way, it’s the ideal accessory to add to your Mastersizer 3000.