When daily operations require elemental analysis of a wide range of inorganic/geological samples, it is often cumbersome, or not possible to setup and maintain a large number of dedicated calibrations to handle such range. In these cases, a widely applicable, but accurate solution is highly desirable. In this application note we demonstrate Malvern Panalyticals unique solution WROXI in combination with Epsilon 4, which is capable to handle a wide range of sample types.

When daily operations require elemental analysis of a wide range of inorganic/geological samples, it is often cumbersome, or not possible to setup and maintain a large number of dedicated calibrations to handle such range. In these cases, a widely applicable, but accurate solution is highly desirable. In this application note we demonstrate Malvern Panalytical's unique solution WROXI in combination with Epsilon 4, is capable to handle a wide range of sample types.

The WROXI BASE application module comprises 15 synthetic multi-elements standards, containing in total 11 different inorganic oxides. Made from traceable compounds WROXI is a primary analytical solution. The standards are delivered as powders to be prepared as fused beads on-site, using the customer’s flux, dilution ratios and methodology.

Each set of WROXI standards is supplied with 15 bottles containing 10 g of powdered standards each, packed under nitrogen, in air-tight plastic bottles. Each set is supplied with drift monitors to maintain the application.

A Claisse LeNEO automatic fusion instrument was used to make all the fused glass beads. Its muffle furnace and excellent insulation properties ensure uniform heating conditions providing excellent repeatability and reproducibility.

Measurements were performed using a Malvern Panalytical Epsilon 4 EDXRF spectrometer, equipped with a 15W, 50 kV silver anode X-ray tube, a high-resolution SDD30 silicon drift detector, 6 beam filters, a helium purge facility, a sample spinner and a 10-position removable sample changer.

Requiring only an electrical connection and fume exhaust, the LeNEO can prepare glass disks for XRF analysis with high reproducibility. In addition to being easy to use, this fully automatic instrument guarantees safety for the operator as well as superior analytical performance in the laboratory.

The Epsilon 4 is an energy dispersive XRF analyzer consisting of a 10 position sample changer and mature software. Powered by the latest advances in excitation and detection technology the Epsilon 4 is a star performer in the benchtop instrument class.

A high-resolution SDD30 silicon drift detector, electronics handling count rates up to 1.5 Mcps at 50 % dead-time, a well-designed optical path and a wide range of excitation capabilities contribute to the Epsilon 4’s uniqueness.

40 mm fused beads were produced by mixing 0.9 g of sample material and 9 g of flux (66 % lithium tetraborate / 34 % lithium metaborate). WROXI standards used to set up the calibration were prepared in duplicate.

The applied measurement conditions are listed in Table 1. The total measurement time per sample was 9 minutes. Net intensities were derived from the acquired spectra by deconvolution, except for Na2O, which was obtained by region of interest (ROI).

| Compounds | kV | uA | Filter | Medium | Detector setting | Measurement time (s) |

|---|---|---|---|---|---|---|

| Na2O, MgO, Al2O3, SiO2, P2O5, SO3 | 4.5 | 3000 | None | Helium | Normal | 300 |

| K2O, CaO, TiO2 | 12 | 250 | Al-Thin | Air | Normal | 120 |

| MnO, Fe2O3 | 20 | 150 | Al-Thick | Air | Normal | 120 |

Table 1: Epsilon 4 measurement conditions

| Compound | Conc. range (%) | Compound | Conc. range (%) |

|---|---|---|---|

| Na2O | 0– 50 | K2O | 0 – 39.9 |

| MgO | 0 - 80 | CaO | 0 - 80 |

| Al2O3 | 0 - 80 | TiO2 | 0 - 80 |

| SiO2 | 0 – 90 | Mn3O4 | 0 - 80 |

| P2O5 | 0 – 60.1 | Fe2O3 | 0 – 81 |

| SO3 | 0 – 58.8 | ||

Table 2: Concentration ranges of the 11 compounds in WROXI standards.

To test the accuracy of the method 12 certified reference materials (CRM) of different geological matrices were prepared as fused beads. The results for the 11 compounds in the CRMs are shown in Table 3. For a wide range of sample types, the measured concentrations show excellent agreement with the certified values.

The calibration was set up using all 15 WROXI standards. The concentration ranges of the 11 compounds in the WROXI standards are shown in table 2.

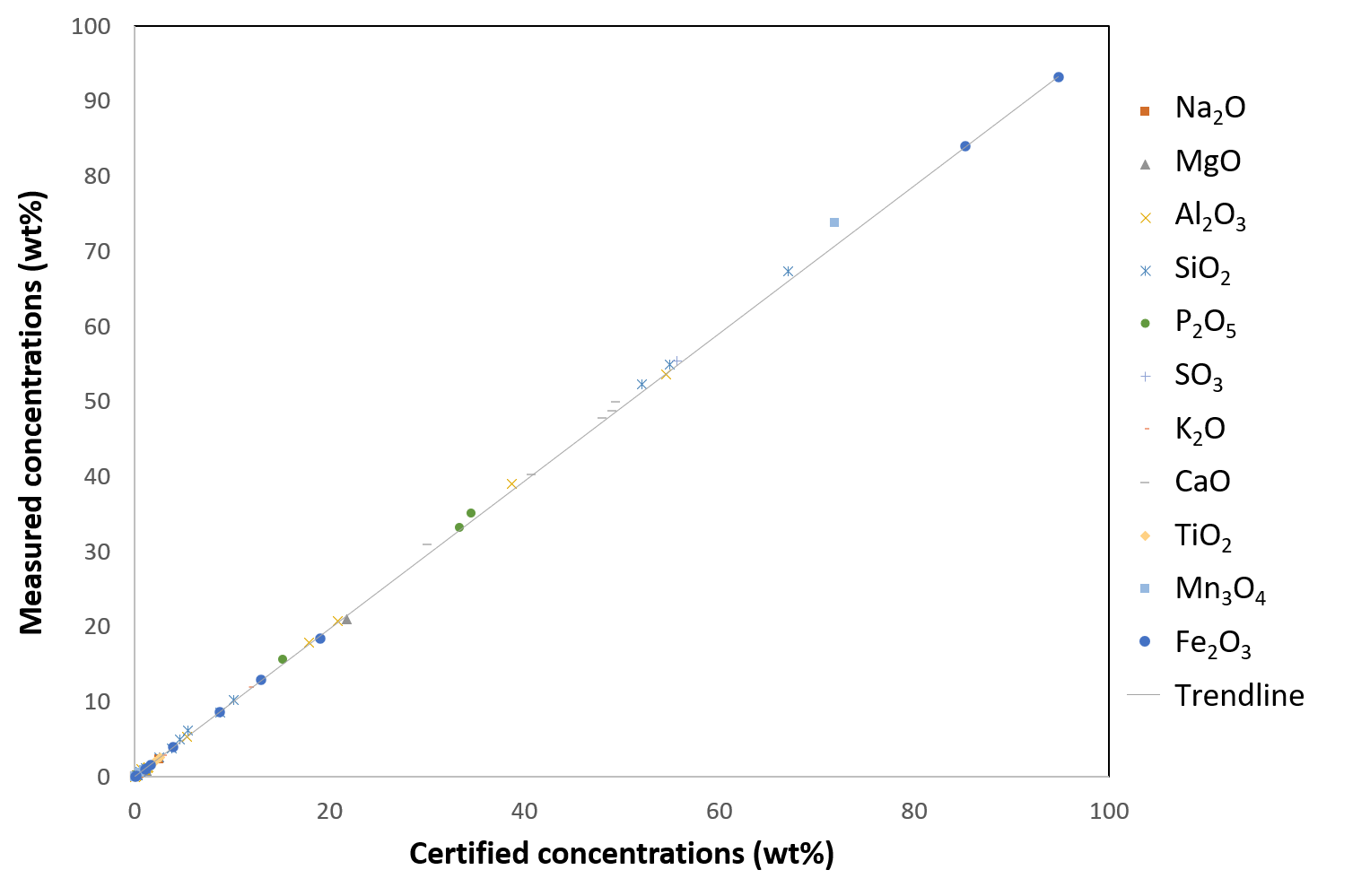

To illustrate the quality of the application graphically, the measured concentrations are plotted against certified values (Figure 1). An excellent agreement between the values is evidenced by the correlation factor of the regression line (R2=0.9997).

| CRM | Type of material | Na2O (wt-%) | MgO (wt-%) | Al2O3 (wt-%) | SiO2 (wt-%) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Crt | Mea | Crt

| Mea

| Crt

| Mea

| Crt

| Mea

| ||

| NIST 696 | Bauxite | 0.10 | 0.012 | < LLD | 54.5 | 53.7 | 3.79 | 3.77 | |

| NIST 679 | Brick clay | 0.18 | 0.20 | 1.25 | 0.77 | 20.8 | 20.7 | 52.1 | 52.3 |

| NIST 76a | Burnt refractories | 0.07 | 0.12 | 0.52 | < LLD | 38.7 | 39.0 | 54.9 | 54.9 |

| GBW 07114 | Dolomite | 0.03 | < LLD | 21.8 | 21.1 | 0.10 | 0.05 | 0.62 | 0.66 |

| GBW 03109 | Gypsum | 0.02 | 0.04 | 1.02 | 0.94 | 0.02 | 0.03 | 0.3 | 0.3 |

| BCS 517 | Iron ore | 0.01 | 0.12 | 0.05 | < LLD | 0.97 | 0.89 | 1.11 | 1.20 |

| NIST 692 | iron ore | 0.01 | 0.12 | 0.04 | < LLD | 1.41 | 1.33 | 10.1 | 10.3 |

| NIST 25d | Manganese Ore | 0.13 | 0 | 5.33 | 5.31 | 2.54 | 2.56 | ||

| NIST 120b | Phosphate rock | 0.35 | 0.24 | 0.28 | 0.22 | 1.06 | 0.98 | 4.68 | 4.95 |

| NIST 120c | Phosphate rock | 0.52 | 0.39 | 0.32 | 0.31 | 1.30 | 1.19 | 5.5 | 6.1 |

| NIST 70a | Potassium Feldspar | 2.55 | 2.33 | 17.9 | 17.9 | 67.1 | 67.4 | ||

| BCS 381 | Slag | 0.20 | 1.03 | 0.82 | 0.67 | 1.02 | 8.78 | 8.55 | |

| CRM | Type of material | K2O (wt-%) | CaO (wt-%) | TiO2 (wt-%) | Mn3O4 (wt-%) | ||||

| Crt

| Mea

| Crt

| Mea

| Crt

| Mea

| Crt

| Mea

| ||

| NIST 696 | Bauxite | 0.009 | <LLD | 0.02 | 0.03 | 2.64 | 2.63 | 0.005 | 0.003 |

| NIST 679 | Brick clay | 2.93 | 2.79 | 0.23 | 0.17 | 0.96 | 0.97 | 0.24 | |

| NIST 76a | burnt refractories | 1.33 | 1.27 | 0.22 | 0.18 | 2.03 | 2.00 | ||

| GBW 07114 | Dolomite | 0.04 | 0.04 | 30.0 | 30.9 | 0.02 | < LLD | 0.01 | 0.007 |

| GBW 03109 | Gypsum | 0.02 | 0.02 | 40.7 | 40.2 | 0.002 | < LLD | < LLD | |

| BCS 517 | Iron ore | 0.01 | 0.06 | 0.05 | 0.03 | 0.06 | 0.12 | 0.94 | 0.97 |

| NIST 692 | iron ore | 0.04 | 0.07 | 0.02 | 0.01 | 0.05 | 0.10 | 0.50 | 0.52 |

| NIST 25d | Manganese Ore | 0.93 | 0.83 | 0.05 | 0.06 | 0.14 | 0.22 | 71.9 | 73.7 |

| NIST 120b | Phosphate rock | 0.12 | 0.17 | 49.4 | 49.9 | 0.15 | 0.13 | 0.04 | 0.03 |

| NIST 120c | Phosphate rock | 0.15 | 0.19 | 48.0 | 47.8 | 0.10 | 0.08 | 0.03 | 0.02 |

| NIST 70a | Potassium Feldspar | 11.8 | 11.9 | 0.11 | 0.10 | 0.01 | 0.02 | ||

| BCS 381 | Slag | 0.09 | 49 | 48.7 | 0.35 | 0.37 | 3.39 | 3.36 | |

| CRM | Type of material | SO3 (wt-%)

| Fe2O3 (wt-%)

| P2O5 (wt-%)

| |||||

| Crt

| Mea

| Crt

| Mea

| Crt | Mea | ||||

| NIST 696 | Bauxite | 0.15 | 0.24

| 8.7 | 8.6 | 0.05

| 0.15 | ||

| NIST 679 | Brick clay | 0.06

| 12.9 | 13.0 | 0.02 | ||||

| NIST 76a | burnt refractories | 0.006

| 0.001 | 1.6 | 1.5 | 0.12

| 0.03 | ||

| GBW 07114 | Dolomite | 0.03 | 0.07

| 0.19 | 0.15 | 0.01 | 0.05 | ||

| GBW 03109 | Gypsum | 55.6 | 55.4

| 0.015 | < LLD | < LLD | |||

| NIST 692 | iron ore | 0.01 | 0.04

| 85.3 | 84.0 | 0.03

| 0.10 | ||

| NIST 25d | Manganese Ore | 0.062 | 3.91 | 3.98 | 0.25

| 0.17 | |||

| NIST 120b | Phosphate rock | 0.50 | 0.08

| 1.14 | 1.07 | 34.6

| 35.0 | ||

| NIST 120c | Phosphate rock | 0.76

| 1.08 | 1.01 | 33.3

| 33.2 | |||

| NIST 70a | Potassium Feldspar | 0.03 | 0.02

| 0.08 | 0.03 | ||||

| BCS 381 | Slag | 0.48 | 0.26

| 19.0 | 18.5 | 15.2

| 15.6 | ||

Table 3. Analytical accuracy: comparison of certified and measured values for eleven major and minor oxides in twelve CRMs of various types. Crt = certified, Mea = measured

Figure 1. Accuracy overview: comparison of measured and certified concentration for all compounds present in the 12 standards.

The results of the validation measurements are summarized and evaluated in Table 4. The results are shown for two groups; for all majors with concentrations above 1%, and for all minors with concentrations between 0.1% and 1%.

The WROXI application in combination with the Epsilon 4 is capable of analyzing most majors with a high accuracy, typically better than 3% relative.

| Na2O | MgO | Al2O3 | SiO2 | P2O5 | SO3 | K2O | CaO | TiO2 | Mn3O4 | Fe2O3 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Av. Ab. Diff. (wt%) | >1% | 0.4 | 0.8 | 0.2 | 0.4 | 0.1 | 0.5 | 0.0 | 0.9 | 0.4 | ||

| Max. Ab. Diff (wt%) | >1% | 0.8 | 0.2 | 0.6 | 0.5 | 0.1 | 0.8 | 0.0 | 1.8 | 1.6 | ||

| Av. Conc. (wt%) | >1% | 6.3 | 17.6 | 21.1 | 27.7 | 5.4 | 43.4 | 2.3 | 37.6 | 25.4 | ||

| Av. Rel. diff (%) | >1% | 5.6 | 4.8 | 0.9 | 1.3 | 2.0 | 1.1 | 0.8 | 2.5 | 1.7 | ||

| # of sample | >1% | 4 | 8 | 10 | 3 | 4 | 5 | 2 | 2 | 9 | ||

| Av. Ab. Diff. (wt%) | 0.1% < c < 1% | 0.09 | 0.52 | 0.35 | 0.02 | 0.09 | 0.24 | 0.06 | 0.04 | 0.03 | 0.02 | |

| Max. Ab. Diff (wt%) | 0.1% < c < 1% | 0.13 | 0.20 | 0.16 | 0.04 | 0.09 | 0.42 | 0.09 | 0.06 | 0.08 | 0.03 | |

| Av. Conc. (wt%) | 0.1% < c < 1% | 0.35 | 0.37 | 0.58 | 0.45 | 0.19 | 0.38 | 0.40 | 0.19 | 0.34 | 0.72 | |

| # of sample | 0.1% < c < 1% | 3 | 3 | 3 | 2 | 3 | 3 | 3 | 3 | 5 | 2 |

|

Table 4: Absolute and relative errors for a selection of oxides calculated from the set of CRMs. Data are presented for two concentration ranges: >1 % and between 0.1 and 1 %. To keep data representative a threshold was set so that data per evaluated compounds was defined by at least two samples in the relevant concentration ranges.

The data in this application note shows the versatility and power of the WROXI application for the analysis of 11 compounds in a variety of sample types. The combination of WROXI, Epsilon 4 and LeNEO offers a unique versatile solution for elemental analysis of minerals. Users will save time setting up and maintaining a set of different calibrations to handle a wide range of sample types. This reduces the need to purchase a large set of certified reference materials. And best of all, the solution gives highly accurate results independent of sample type. Users can start analyzing directly, with minimal knowledge about the expected composition.